27

10.Inspection and maintenance before riding

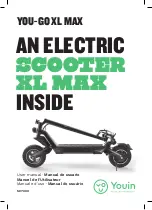

CHECKING THE SPARK PLUG

Remove the cap of high tension cable. (Use a plug wrench in tool

box to remove the spark plug by turning it counterclockwise.)

Check the electrode if it is dirty or fouled by carbon deposits.

Remove the carbon deposits on the electrode with steel wire, and

clean the spark plug with gasoline, then, wipe dry with a rag.

Check the electrode, and adjust its gap to 0.6~0.7mm. (Check it

with a feeler gauge)

Hand tight the spark plug as far as it can go and then tighten it

another 1/2~3/4 turns with a wrench.

WARNING:

The engine is very hot after running. Pay attention

not to get burned.

※

Use only spark plugs suitable for the engine specifications of

this scooter recommended by the manufacturer. (Refer to

specifications.)

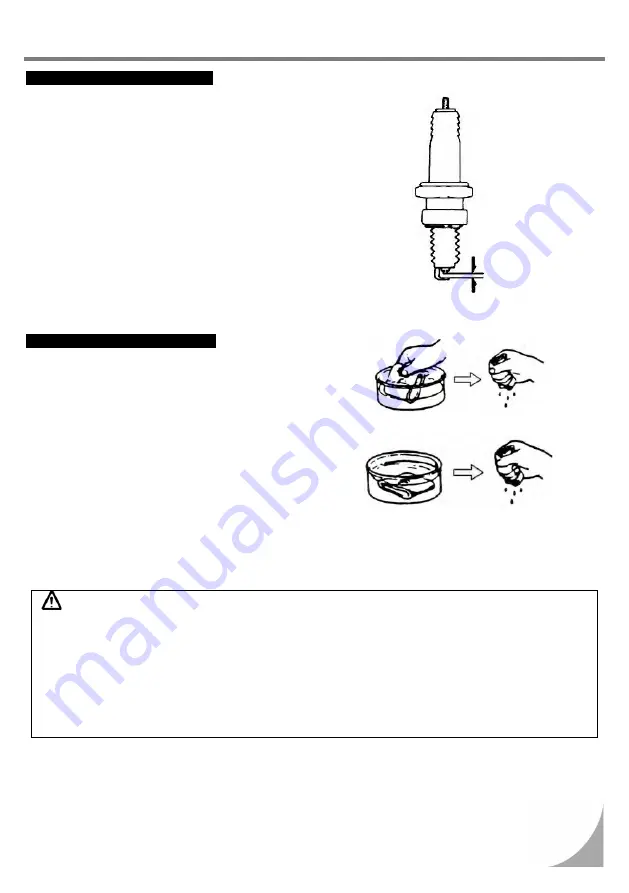

CHECKING THE AIR CLEANER

《

DISASSEMBLE PRCEDURE

》

1. Remove the screw of air cleaner cover.

2. Remove the air cleaner cover and then the

cleaner’s element.

3. Clean or replace the element.

(For checking interval please refer to

maintenance schedule.)

4. Refer to figures shown on the right for air

cleaner element cleaning steps.

Procedures for cleaning air cleaner element:

1.cleam.

2.squeeze dry.

3.soak in engine oil.

4.squeeze dry

《

ASSEMBLE PRCEDURE

》

Assemble the air cleaner in reverse order of disassemble.

CAUTION:

Dust deposit is one of the major causes of reducing output horsepower and increasing fuel

consumption.

Change the air cleaner element more frequently to prolong the engine’s service life if the scooter is

driven on dusty roads very often.

If air cleaner is installed improperly, dust will be absorbed into cylinders, which may cause a

premature wear and reducing output power and engine life.

Be careful not to soak the air cleaner when washing the scooter. Otherwise, it will cause engine

hard to start.

0.6~0.7mm

Содержание JET 100 series

Страница 1: ...OWNER S MANUAL...