GB.TBXZ342.130915

Registered design. The company reserves the right to make changes without prior notice.

2 www.swegon.com

2. Installation

2.1 Pipework Package.

1. Install the pipework package at a suitable location in

the fan room.

Wall mounting

Remove the wall mounting bracket from the pipework

package and secure it to a suitable place on a wall. In

order to reach and unfasten the wall mounting bracket,

you must first dismantle the front panel of the sheet-metal

casing.

Floor mounting

A stand for floor mounting, TBXZ-2-43, is available as an

accessory, see illustration to the right. Secure the stand to

a suitable spot on the floor. In order to reach the pipework

package and secure it to the stand with screws, you must

first dismantle the front panel of the sheet-metal casing.

2. Mount the pipework package onto the wall mounting

bracket/floor stand.

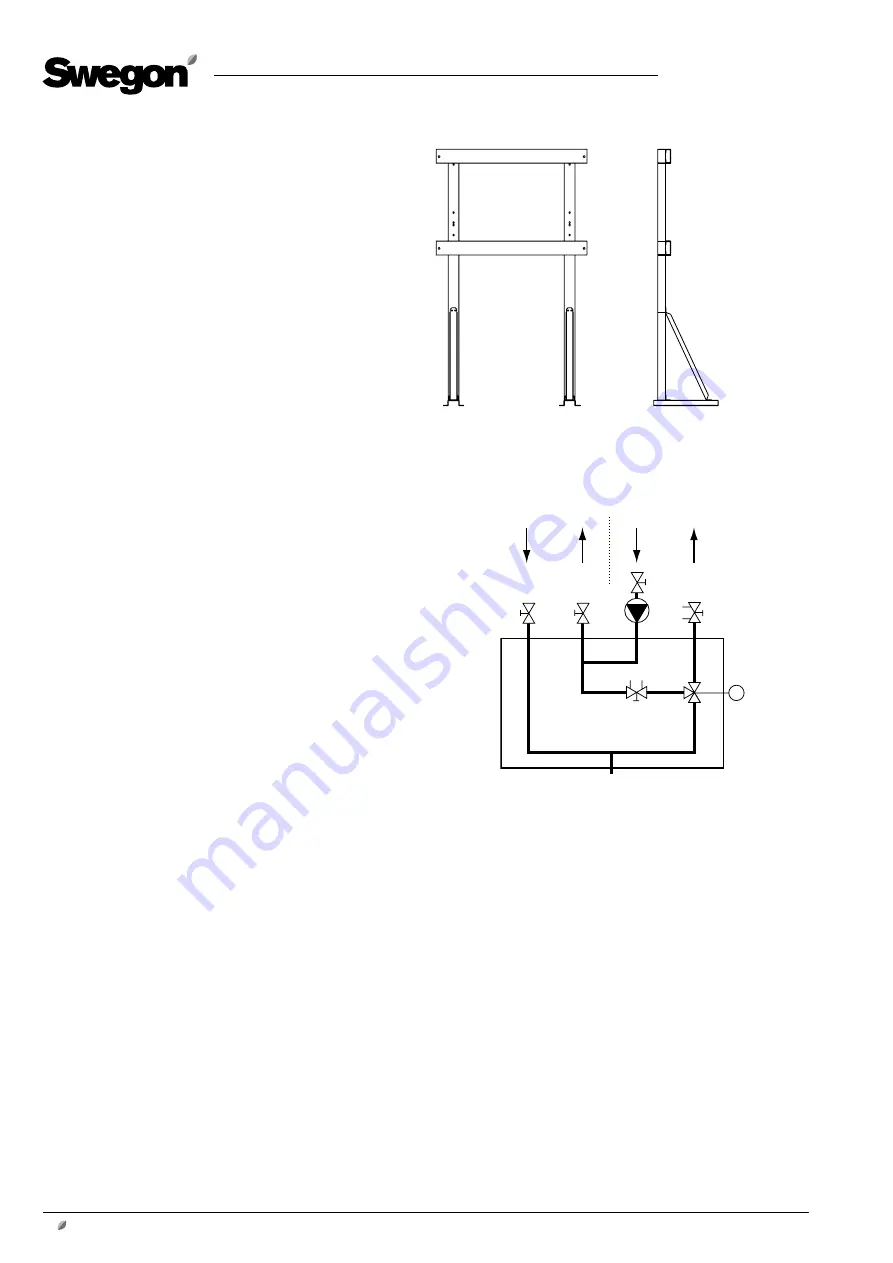

3. Fit the pump to the pipework package. Give careful

attention to the direction of flow. See the label on the

front of the pipework package and the illustration to the

right. It may be necessary to dismantle the drive side of

the pump and turn it so that the electrical terminal box

will be positioned upward. This can be done after remov-

ing four socket head cap screws.

4. Mount the shut-off valve + pipes onto the pump.

5. Mount the pressure expansion vessel and accessories.

2.2 Control unit.

The control unit is designed for wall mounting should be

mounted at an appropriate location. Make sure that you

position the safety isolating switch on the control unit 0.6

– 1.9 metres above floor level.

2.3 Installing the pipework

The pipework between the heat exchanger coils and the

pipework package should be installed and insulated in a

professional manner by a ventilation and sanitation fitter,

according to customary trade standards and regulations.

Connect the heat exchanger coils for counter-flow cir-

culation according to the arrows on the coil connection

branches. Incorrect connection may cause a reduction in

efficiency. Make sure that the pipework package and the

connecting pipework do not block inspection of the other

functional sections.

Check that the deadweight of the pipework and/or the

expansion forces will not be applied to liquid connections.

Use an appropriate sealing/jointing compound for sealing

the threads on the heat exchanger connections.

Connect the safety valve, appropriately using a hose, to a

collecting vessel (not supplied by Swegon ).

M

Supply air

Extract air

The height from

floor level to the

thermometers on

the installed pipe-

work package is

1480 mm.

2.4 Temperature sensor

A type strap-on temperature sensor is supplied with the

pipework package. Secure the sensor onto the return

pipe, as shown in the basic circuit diagram on page 1, for

instance by means of a bundling strap. The sensor is used

as a limiting sensor to counteract freezing.

Wire the temperature sensor leads to terminals 107-108 in

the control unit of the pipework package.