k

p

q

⋅

=

k

p

q

=

( )

2

COLIBRI Free x

Tomelilla

Sweden

XXX

k = XX

k

p

q

TILLUFT / SUPPLY AIR

TILLUFT / SUPPLY AIR

FRÅ

NLU

FT /

EXTR

ACT AI

R

Installation

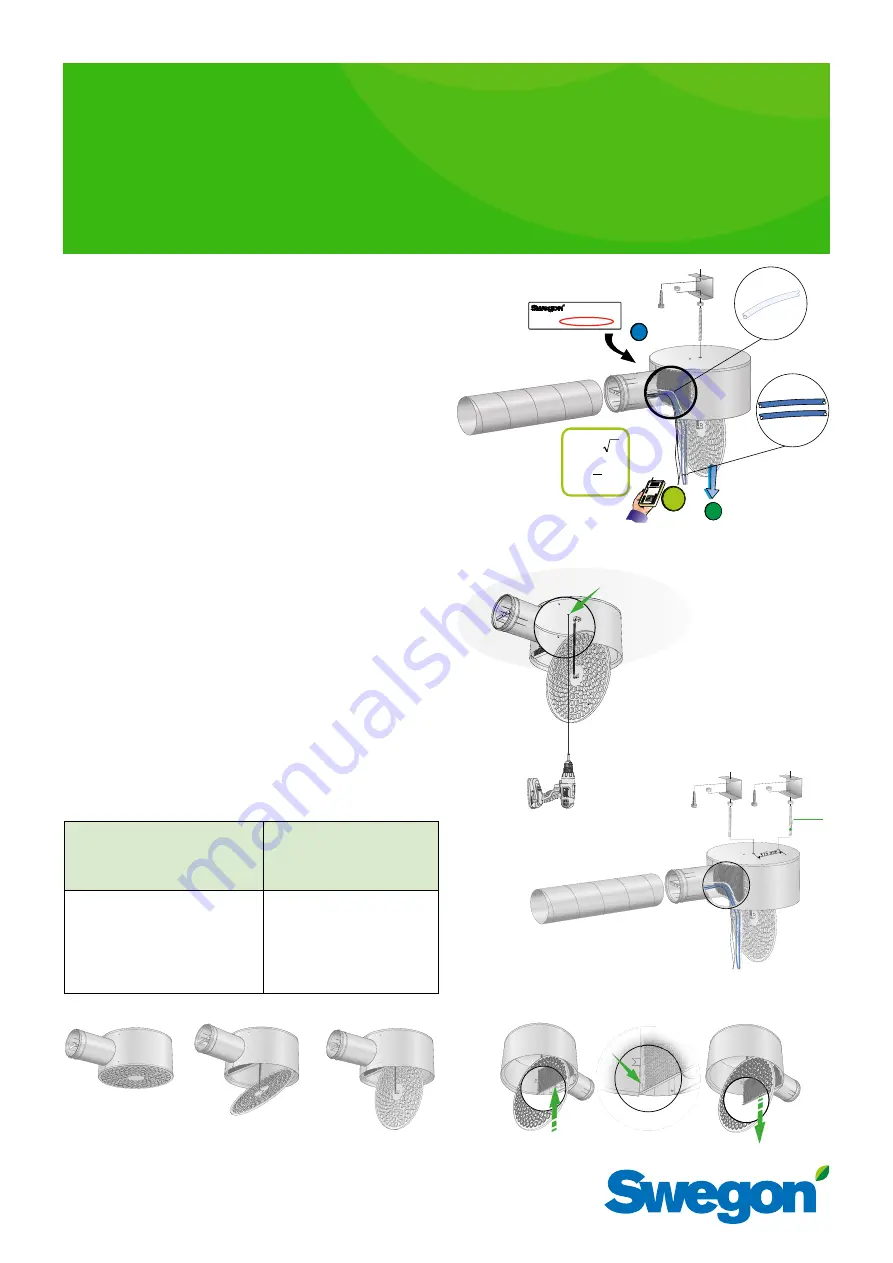

The air diffuser is normally suspended from the ceiling. An M8

pop nut, i.e. a threaded grommet that facilitates installation, is

in the centre of the top of the air diffuser. On the size 315 and

400 air diffusers, there are two M8 pop nuts for more stable

mounting, see figure 2 and 3.

Commissioning

Commissioning should be carried out with the diffuser face

mounted. Pull the measuring tubes and the damper adjustment

cords out of the air diffuser through one disc in the diffuser

face. Then connect the manometer to the correct measuring

tube(s): two blue tubes for supply air and one transparent tube

for extract air. The rated coefficient of performance of the air

register can be used in a calculation to determine the required

commissioning pressure. Conclude commissioning by adjusting

the damper to the correct blade position, tie a commissioning

knot in the damper cords to indicate the damper position. See

Figure 2. The K-factor is specified on the product’s identification

label and last in these instructions.

Maintenance

•

Clean the air diffuser if needed with lukewarm water and

dishwashing detergent added.

•

The duct system can be accessed and lightly pulling the

spring-loaded diffuser front downwards and then tilting,

see figure 1.

•

Dismantle the perforated air distribution plate located on

the inlet as shown in figure 4.

•

Loosen the damper in the inlet from its bayonet fastening

by rotating to the side.

Length of straight duct

Type of obstruction upstream of

Length of straight duct

upstream of the COLIBRI

Free

COLIBRI Free

m

2

= 5%

m

2

= 10%

One 90° bend

3 ·Ød

2 ·Ød

Two 90°bends in the same plane

4 ·Ød

2 ·Ød

Two 90° bends in alignment at

right angles to one another.

4 ·Ød

2 ·Ød

One 45° damper

6 ·Ød

3 ·Ød

One T-piece

4 ·Ød

3 ·Ød

m

2

= accuracy of the method according to NVG’s report T32:1982

Figur 1. Spring-loaded diffuser front.

Figure 4. Dismantling of the perforated air distribution plate.

Figure 3a. Alternative installation.

k-factor

q

= flow reading l/s

p

= current pressure reading (Pa)

k

= commissioning factor

Figure 2. Installation. Commissioning. Maintenance.

Applies only for

size 315 & 400

Figure 3b. Extra M8 pop nut, size 315 and 400.

COLIBRI

Free a

Installation – Commissioning – Maintenance

20181004