Swimming Starting Block / OSB 11

Version 1.7

3454.504.02

Page 13

5 PREVENTION AND MAINTENANCE

Equipment installed in aquatic complex, often sealed with a high moisture level, require special attention in

regards to their maintenance. In fact, the stainless steel parts found on ladders, fences or swimming starting

blocks can have corrosion if they are not frequently cleaned.

Stainless steel is an excellent product that needs to be very clean to keep its stainless quality.

MAINTE

NANC

E

When you receive your new equipment, it is important to establish a maintenance program to

avoid the stainless steel parts to deteriorate. Indeed, lack of maintenance can make the

chromium oxide film inefficient, which could cause corrosion on your equipment. A dirty

surface is the biggest ally of corrosion and your biggest enemy.

Dirt, grease and deposit left by users or by contaminated water deposit must be removed by cleaning the

surface with

fresh water

(do not use the pool’s water) and wiped, if possible, with a clean dry cloth.

A

basic cleaning

of the starting blocks’ inner and outer surfaces (without disassembling) must be done

regularly,

preferably every week

.

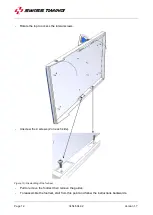

A

thorough cleaning

with removal of the top (see manual) must be done

regularly

, several times a

year, depending on the degree of contamination of the stainless steel. You must pay extra attention to

the RBD (Relay Break Detection) and the handles (backstroke ledge).

Concerning dismantling, it is imperative to use tools that are specially designed for stainless steel.

Applying a hydrophobic (insoluble in water) silicone type B 431 also increases the protection of the

sensitive areas of the OSB14 against corrosion.

A tube of this silicone is provided with each mounting set and must be used in case it is dispersed and

after each thorough cleaning or rehabilitation.

RE

M

E

DIAT

IO

N

If your equipment is already showing significant dirt deposits, you need to get rid of them in

order that the oxygen from the air gets in contact with the chromium in the stainless steel to

form the protective chromium oxide film.

A thorough cleaning with fresh water

should be sufficient. If some dirt remains, rub with a nylon pad

or a cotton cloth. Make sure the pad you use is not rough to prevent it damaging the protective film or the

aesthetic finish of the product.

After a

thorough cleaning

, clean the stainless steel with fresh water

twice a week

during a few months

and then decrease the frequency.

Never use a metal brush, steel wool, emery paper or any abrasive material to clean. Indeed, stainless

steel would be contaminated by a large quantity of undesirable particles which inevitably would cause

rust stains.

OSB properly maintained

OSB poorly maintained

Содержание SWISS TIMING 3454.013

Страница 1: ...3454 504 02 Version 1 7 Edition March 2020 OSB 11 Swimming Starting Block User s Manual...

Страница 4: ......

Страница 20: ...Page 16 3454 504 02 Version 1 7 NOTES...