www.SuperiorFireplaces.US.com

126903-01A

8

INSTALLATION

Continued

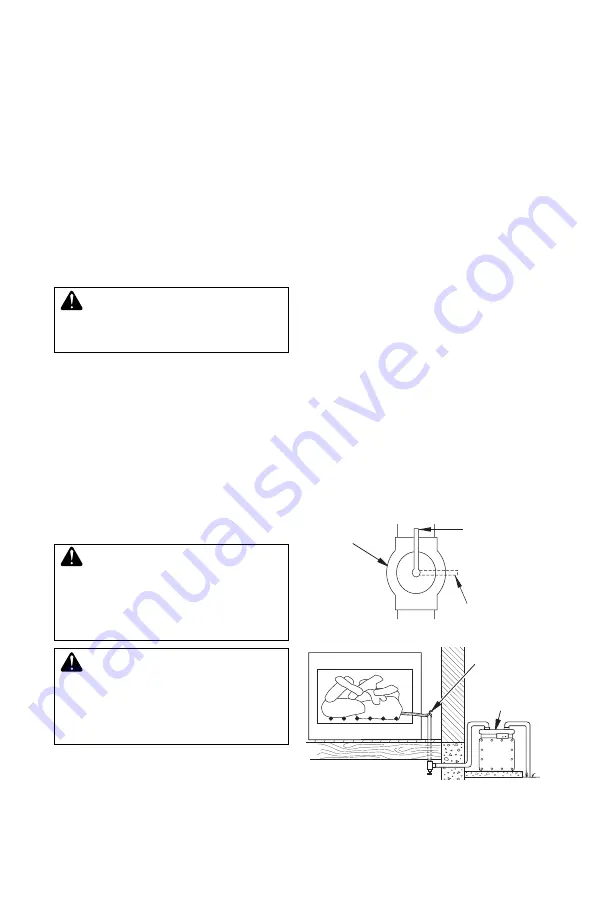

Installation must include an equipment shutoff

valve, union and plugged 1/8" NPT tap. Locate

NPT tap within reach for test gauge hook up.

NPT tap must be upstream from log set (see

Figure 4).

IMPORTANT:

Install equipment shutoff valve

in an accessible location. The equipment

shutoff valve is for turning on or shutting off

the gas to the appliance.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant from

going into pipe. Excess sealant in pipe could

result in a clogged burner injector.

WARNING: Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

We recommend that you install a sediment

trap (not supplied with log set) in supply line

as shown in Figure 4, page 7. Locate sediment

trap where it is within reach for cleaning. Install

in piping system between fuel supply and ap

-

pliance. Locate sediment trap where trapped

matter is not likely to freeze. A sediment trap

captures moisture and contaminants. This

keeps them from going into log set controls.

If sediment trap is not installed or is installed

wrong, log set may not run properly.

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply a

noncorrosive leak detection fluid

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

Pressure Testing Gas Supply Piping

System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance

main gas valve (control valve) and equip-

ment shutoff valve from gas supply piping

Figure 6 - Checking Gas Joints

Gas Meter

Equipment

Shutoff

Valve

system. Pressures in excess of 1/2 psig

3.5 kPa) will damage appliance regulator.

2. Cap off open end of gas pipe where equip

-

ment shutoff valve was connected.

3. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4. Check all joints of gas supply piping sys

-

tem. Apply noncorrosive leak detection

fluid to gas joints. Bubbles forming show

a leak.

5. Correct all leaks at once.

6. Reconnect log set and equipment shutoff

valve to gas supply. Check reconnected

fittings for leaks.

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Fig-

ure 5).

2. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

3. Check all joints from gas meter to equip

-

ment shutoff valve (see Figure 5). Apply

mixture of liquid soap and water to gas

joints. Bubbles forming show a leak.

4. Correct all leaks at once.

www.fmiproducts.com

115425-01F

8

INSTALLATION

Continued

Figure 6 - Checking Gas Joints

Gas Meter

Equipment

Shutoff Valve

HEARTH KIT ASSEMBLY AND

INSTALLATION

Kit Assembly - Ramp Pan Burner

1. Determine which side gas line feeds into

fireplace.

This log set is factory set up for

right side (facing) gas feed. If your gas line

is on the right side, go to

Installation and

Gas Connection

. If your gas line is on the

left side of

fireplace,

proceed with steps 2

through 4 below.

2. Remove nuts securing gas inlet venturi to

bottom of burner.

3. Remove venturi from pan taking care not to

damage gasket between venturi and pan.

4. Reverse direction of venturi and reattach

to bottom of pan using factory nuts.

Figure 7 - Venturi Gas Connection

Burner Orifice

(Factory Installed)

Burner Inlet Venturi

(Attached to Pan

Bottom)

Gas Connector

Tube

Adapter

Fitting

Burner Inlet Fitting

(Factory Installed)

Installation and Gas Connection

1. Place ramp burner assembly in center

of

fireplace

floo

r. Make sure front of pan

faces forward.

2. Thread gas supply

fitt

ing to

fi

replace gas

supply pipe. Use thread sealant.

3. Install gas connector tube to gas supply

fitting.

Carefully shape tube to attach to

adapter

fitting.

Be careful not to cause

kinks in tube.

4. Attach opposite end of gas connector tube

to gas inlet fitting on end of venturi.

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Fig-

ure 5).

2. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

3. Check all joints from gas meter to equip-

ment shutoff valve (see Figure 6). Apply

noncorrosive leak detection

fluid

to gas

joints. Bubbles forming show a leak.

4. Correct all leaks at once.

TESTING BURNER FOR LEAKS

1. Generously apply noncorrosive leak

detection

fl

uid to all connections.

WARNING: Never check for

gas leaks with ope

n fl

ame.

2. Light burner with shutoff valve no more

than half open and holding a match

slightly in front of pan (see

Lighting In-

structions

, page 10).

3. Inspect all connections for bubbles, raw

gas odor, or

fl

ame from any area other than

burner (leaks). If leaks are detected, shut

off gas valve immediately. Tighten, or reas-

semble loose connection(s) using pipe joint

compound until burner system is leak free.

4. When burner is tested and leak free, ob-

.

r

e

n

r

u

b

n

o

e

m

a

fl

f

o

s

e

u

g

n

o

t l

a

u

d

i

v

i

d

n

i

e

v

r

e

s

Make sure all ports are clear and producing

fl

ame evenly across burner. If any ports

appear blocked, clear by removing burner

manifold and reaming ports with a modi

fi

ed

paper clip or other suitable tool.

5. When

finished

testing, turn gas shutoff

valve OFF to extinguish all flames.

Figure 5 - Equipment Shutoff Valve

Open

Closed

Equipment

Shutoff

Valve