Operating Instructions:

This unit can be operated with the engine on or off.

It operates like any other battery powered tool drawing power from

the battery. Its performance will vary with the battery’s state of

charge. Actual operating time available with the engine off will vary

depending on your battery’s size, age, temperature and state of

charge. Typically with the engine running the charging system will

provide slightly more voltage to the unit thereby increasing the unit’s

performance.

Unpack the unit and completely un-wrap the power cord and inspect

for damage.

Place the unit on a dry, level surface.

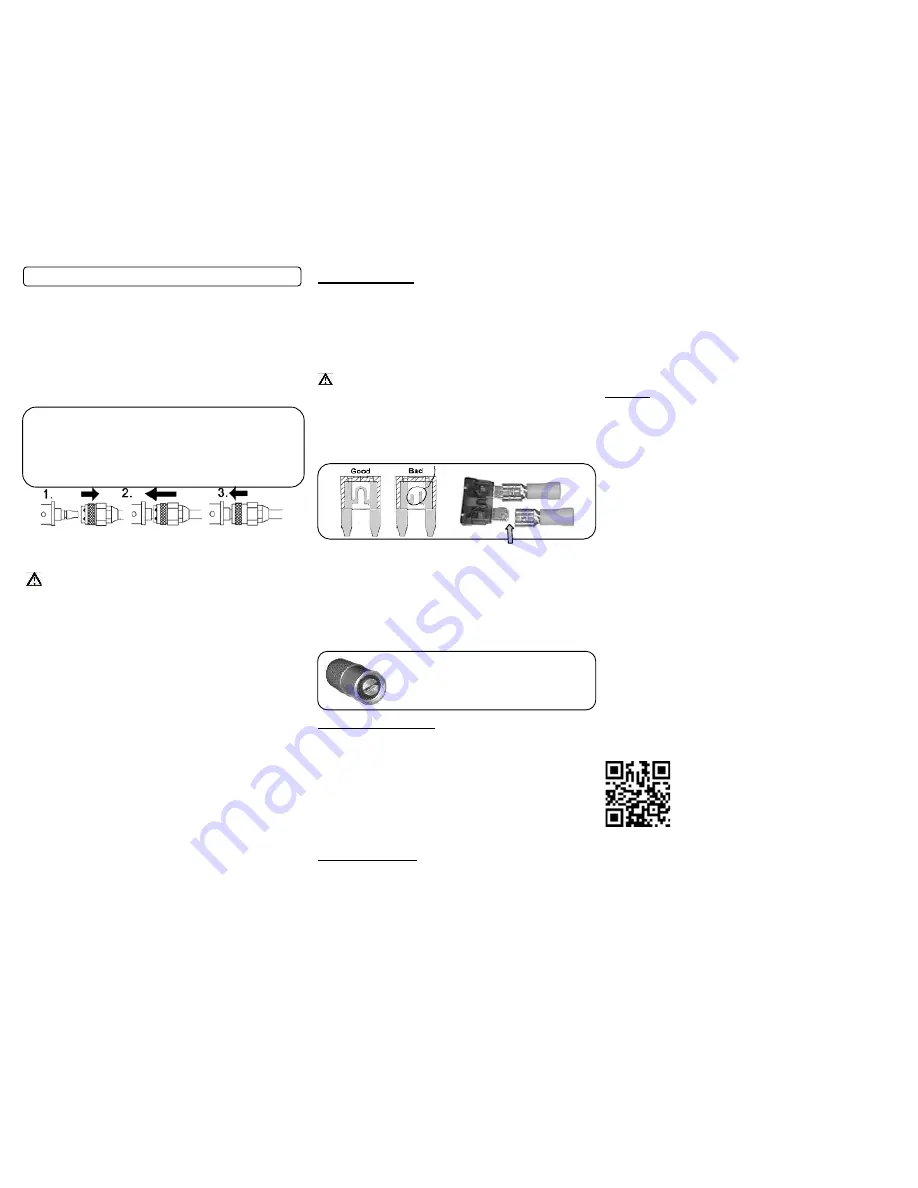

Connect the air supply hose to the unit using the quick connect

fitting as shown in Fig. 3 below.

1. Slide the retaining snap ring back.

2. Slide the fittings together firmly.

3. While holding fittings together firmly slide the outer ring forward to

lock . See image below.

4. Install the red air filter housing as shown below. Only tighten by

hand.

WARNING

This compressor connects directly to a 12-Volt power source. It is

recommended that you

ALWAYS CONSULT YOUR OWNERS

MANUAL FOR VEHICLE SPECIFIC INSTRUCTIONS FOR

LOCATING THE CORRECT ATTACHMENT POINTS

.

Take care to avoid moving parts such as fan blades

.

5. Identify the battery posts as either POSITIVE (+) or NEGATIVE

(-). Positive posts or terminals are typically bigger than negative

posts or terminals. Some vehicles have a positive terminal to hook

the cable to that is not actually on the battery itself. Connect the

positive cable to the positive terminal of the battery.

6. Attach the black / negative cable to the engine block or alternator

mounting-bracket of the vehicle, as far from the battery as possible.

Do not connect the negative cable to the negative terminal of the

discharged battery, as this can generate a spark, which could cause

the battery to explode.

7. Test the connections by switching the compressor to “on” and air

will begin to flow.

8. Connect the valve adapter to the threaded section of the tire valve

or one of the accessories provided in Fig 2.

9. Switch the unit “On” to begin inflating. Switching the unit off to

observe the gauge will provide the most accurate pressure reading.

Remove the inflator from the item when the manufacturer’s

recommended pressure has been achieved. Confirm the pressure is

correct with a second gauge.

10. Allow the unit to cool, remove the hose and Air filter. Repack in

the original box to prevent damage during storage. Store in a dry

location.

Troubleshooting:

In the event the unit fails to operate:

Check your connections

:

Be sure the battery clips are seated securely with a firm “bite” on

the battery terminal and connection point.

Inspect the fuse:

WARNING:

Disconnect the cables from battery prior to inspection and removal

of the fuse. Located on the power cord you will find a black plastic

fuse holder containing a ATC 20A Standard Blade Automotive type

fuse. Carefully remove the cover. Remove and visually inspect

the fuse. If it's blown, you'll see a melted

"bridge"

going between

the two blades. See the circle in the image below. Replace if

necessary.

Read this it’s very important

: When replacing the fuse be sure

both metal blades are inserted into the metal connectors inside the

fuse holder not alongside.

Air leaking from EZ twist inflator:

Inspect the end of the inflator for dirt and check your valve stem for

damage. Also check that the rubber seal inside the inflator end is

not damaged.

Seen here is how your inflator end should look.

Note the rubber seal around the air slot.

California's Proposition 65

WARNING:

This product contains chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm. This product and its components should not come in contact

with food or drinking water. Please wash your hands with soap and

water after touching this product or its components.

For complete information regarding Proposition 65 please visit the

following CA.gov site.

http://oehha.ca.gov/prop65/background/p65plain.html

Limited Warranty:

This portable High Volume Air Compressor is warranted by Q

Industries, Inc., to be free of defects in materials and workmanship

for a period of 2 years from date of original purchase.

This warranty does not cover units damaged by abuse or operated

above recommended pressures. There is no other warranty,

hereunder, either expressed or implied. In the event of a defect, the

air compressor will be repaired or replaced at our option. Please

contact Q Industries, Inc. by email or telephone to obtain a return

authorization number and a shipping address. Q Industries, Inc. shall

not be responsible for any other incidental, contingent, or

consequential charges or damages. This warranty gives you specific

legal rights, and you may also have other rights which vary from State

to State. Some States do not allow limitations on how long an implied

warranty lasts or the above limitations or exclusions may not apply to

you.

Service:

In the event you do have a problem we’re here to help. We pride

ourselves on customer service and will do our best to help you out.

Do Not

return this product to the store. Contact customer service first.

They are available M-F 9 to 5 Arizona time, which is like California

except in the winter when we’re an hour earlier.

The fastest way is to contact us via Email. No web? Don’t worry.

Phone, Fax or Mail us. If you choose to call the line goes right to

voice mail. Calls are returned by the next business day. Please

remember to include your name, address and phone number.

Believe it or not sometimes people forget.

You can find replacement hoses, parts and accessories at:

www.SuperFlowAir.com

E Mail:

Warranty registration:

Go to SuperflowAir.com

Phone:

954-689-2263

Fax:

303-568-7700

Mailing Address:

Paper mail only please.

This corporate address cannot accept packages, only paper mail.

Do not ship items

for service to this address. Contact customer

service for the return shipping address.

Q Industries Inc.

4727 E Bell Road

Suite 45-202

Phoenix AZ. 85032

www.SuperFlowAir.com