25

5) Specification

6) Caution

①

Before using, make sure to check voltage.

(This machine is set for both 100/220voltage but set for 220V upon shipment.

To use 110V, adjust Switching switch under the machine)

7) Troubleshooting

①

When the machine doesn’t work, check and replace fuse or switch.

②

When the bobbin shaft doesn’t stop, replace parts of volume or “TR1” on board.

③

When the machine doesn’t start or stop, replace start switch or IC.

④

When the voltage is not suitable, the machine may not work with sound of ‘click’.

At that time, replace parts of “Q1” on board.

Model

BW-02

(Bobbin Winder)

3,200rpm

AC 110/220V

50/60Hz

10W

420

×

155

×

125

3.9kg

450

×

190

×

170

4.5kg

Speed

Power Supply

Machine Weight

Package Weight

[ Fig. 25 ]

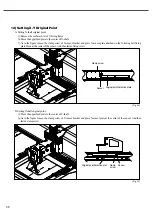

10) Adjusting the Height of the Presser Foot

①

Unfasten presser foot screw

①

with the needle bar at the lowest

position.

②

Adjust the height so that the presser foot botton comes

0.5mm(the thickness of the thread used)above the sewing

material. Then, tighten the screw.

[ Caution ]

After adjusting the height of presser foot, confirm the position

of wiper.

·

Too excessive gap can cause jumping.

·

Insufficient gap can cause a failure in thread adjustment.