1

An unpleasant smell may be detected only where there is a bad compost (See "Trouble Shooting

your Compost") and then only when there is poor air flow such that insufficient air is being

sucked into unit.

-16-

Symptoms

Possible Causes

Remedies

POOR

AIR

FLOW

THROUGH

UNIT

Unit is in an air-tight

location and the fan

cannot pull air in.

Provide air supply.

Fan (110 Volt or 12V)

has failed.

Remove the bowl liner and reach back to flick the 110V fan

blades. Remove and try the same thing with the 12 V fan. If

this does not restart the fan, then the fan should be replaced.

Instructions are included with the replacement fan.

Device other than Sun-

Mar diffusor is installed.

Your device may be discouraging air movement. If so,

replace with a Sun-Mar diffusor.

Sun-Mar diffusor iced

up.

Diffusor is probably not needed in winter. Remove until

spring.

Vent has a water trap

where condensation is

collecting and causing a

partial or total blockage.

Re-install the 2" vent so there are no longer any low points

where condensate can collect. If re-installation is not possible,

drill a small hole in the bottom of the low point (preferably

outdoors) to allow condensate to drain. (Note; watch for icing in

winter).

2" vent stack has too

many bends and/or

horizontal lengths, or 4"

vent stack is not straight

enough.

1. Re-install the 2"vent stack to reduce number of bends/

excess horizontal lengths, or straighten 4" vent.

2. If the 2" vent stack cannot be further straightened,

remove the fan assembly and reduce the amount of

recirculating air by covering up the area between the fan

exhaust and the 90

o

vent intake elbow with duct tape or

similar. If 4" vent is not straight install a 12 Volt fan.

Blockage in stack

Check air movement at top of stack. If very little, and other

possible causes eliminated, disassemble stack until blockage

found. Re-assemble, and/or insulate if blockage caused by ice

build up.

UN-

PLEASANT

SMELL

Vent stack is leaking at

joints or is broken.

Make sure vent stack and fan assembly gaskets are air tight.

Seal joints/gasket with silicone to permit possible future

access. Vent joints away from the unit can be glued.

See "Poor Air Flow"

causes (above)

1

See "Poor Air Flow remedies (above).

Bad compost.

See earlier section on "Trouble Shooting Your Compost".

-5-

rear, and the 4" vent from the top of the toilet.

The partial vacuum which the fan creates within

the toilet ensures there can be no smell.

Meanwhile, when the 110 Volt fan is not

working, the 4" vent stack acts like a chimney

on a wood stove to provide negative pressure

and prevent odors.

In the 110 volt mode, in addition to a fan, the

evaporation process is further assisted by a

thermostatically controlled heating element

located in a sealed compartment under the

evaporating chamber. This heating element

maintains warmth in the evaporating chamber,

and the indirect warmth also assists the

composting process.

A safety drain at the rear of the composter exits

from both left and right at the rear. These drains

are supplied plugged, but if the unit is to be used

heavily or without 110 volt electricity, one exit

should be connected to drain off any excess

liquid.

Start Up and Use

The "EXCEL AC/DC” requires little

maintenance. To start, put 3-4 gallons of peat

moss mix and a quart of rich top soil in the

drum, (or use Sun-Mar Microbe Mix), moisten

with warm water, and spray "Compost Quick"

into the drum and evaporating chamber under

the drawer. Thereafter, a cupful of peat mix

should be added after every bowel movement.

Although the peat mix included with the unit is

specially formulated for optimum performance,

regular peat moss may usually be used as an

acceptable substitute.

Every third day while the toilet is in use, the

drum should be rotated to mix and aerate the

compost. The drum should be given 4-6

complete revolutions, by turning the handle in a

clockwise direction (Seven turns of the

handle is required for each drum rotation).

To extract compost into the finishing drawer,

pull the drum lock, to enable the handle to

turn anti-clockwise and the drum clockwise.

The drum should be rotated at regular speed,

and as it does so the drum door remains open,

and compost drops automatically into the

finishing drawer.

While it is entirely up to the user, we suggest

that under normal conditions electricity can be

disconnected if the toilet is not going to be

used for over a week.

Winter Use

Because "Sun-Mar" units are made of

fibreglass and high grade stainless steel;

freezing temperatures will not damage the

toilet. Composting action, however, decreases

as the temperature drops, so for extended

winter use attempts should be made to try and

keep the toilet above 60

o

F (15

o

C) if possible.

The vent stacks should be insulated to

minimize condensation in the pipe and avoid

ice blockages.

If the toilet is in an unheated space and 110

volt electricity is avaialable, it may be

necessary to keep the toilet plugged in, install

a fan speed control on the toilet so that the fan

is drawing in very little air, and put a blanket

over the toilet.

For periodic use in winter, even where the

compost in the drum is frozen, if there is

enough room in the drum, the toilet may be

used as a “holding tank”, until the compost

warms up and the microbes emerge from

dormancy.

Содержание EXCEL AC/DC

Страница 2: ...2 19...

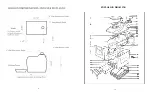

Страница 6: ...6 15 EXPLOSION DRAWING...