23

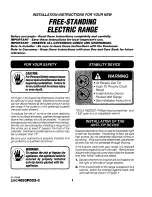

Installation Instructions

LOCATION

Do not locate the range where it may be subject to

strong drafts. Any openings in the floor or wall behind the

range should be sealed. Make sure the openings

around the base of the range that supply fresh air for

combustion and ventilation are not obstructed by

carpeting or woodwork.

Your range, like many other household items, is heavy

and can settle into soft floor coverings such as

cushioned vinyl or carpeting. Use care when moving the

range on this type of flooring. It is recommended that

the following simple and inexpensive instructions be

followed to protect your floor.

The range should be installed on a sheet of plywood (or

similar material). When the floor covering ends at the

front of the range, the area that the range will rest on

should be built up with plywood to the same level or

higher than the floor covering.

This will allow the range to be moved for cleaning or

servicing. Also, make sure your floor covering will

withstand 180°F. (Seethe Installation Safety Instructions

section.)

Make sure the cabinets and wall coverings around your

range can withstand the heat generated (up to 200°F)

by the range. (See the Installation Safety Instructions

section.)

IMPORTANT!

Remove all tape and packaging. Make sure the burners

are properly seated and level.

Take the accessory pack out of the oven and/or

drawer.

Check to be sure that no range parts have come loose

during shipping.

PROVIDE ADEQUATE GAS SUPPLY

Your range is designed to operate at a pressure of 5" of

water column on natural gas or, if designed for LP gas

(propane or butane), 10" of water column.

Make sure you are supplying your range with the type of

gas for which it is designed.

This range is convertible for use on natural or propane

gas. If you decide to use this range on LP gas,

conversion must be made by a qualified LP installer

before attempting to operate the range on that gas.

For proper operation, the pressure of natural gas

supplied to the regulator must be between 6" and 13" of

water column.

For LP gas, the pressure supplied must be between 11"

and 13" of water column.

When checking for proper operation of the regulator,

the inlet pressure must be at least 1" greater than the

operating (manifold) pressure as given above.

The pressure regulator located at the inlet of the range

must remain in the supply line regardless of whether

natural or LP gas is being used.

A flexible metal appliance connector used to connect

the range to the gas supply line should have an I.D. of 1/

2" and be 5 feet in length for ease of installation. In

Canada, flexible connectors must be single wall metal

connectors no longer than 6 feet in length.

1

Содержание PRO246SS

Страница 30: ...30 ...