SummaSign Pro SL D-series Cutters

User’s Manual

Operation

2-19

2.5.1

TANG. KNIFE CALIBRATION

The purpose of the knife calibration procedure is to detect and, if necessary, to

correct problems related to the concentricity of the TANGENTIAL knife blade.

This procedure should only be run when required. If cut quality problems are

apparent when a new knife is installed, perform a knife calibration test as

described in the following paragraphs.

During the knife calibration procedure, the cutter will cut a series of test

patterns that will allow you to identify errors in knife rotation and concentricity.

Corrective measures can then be taken using the control panel keys.

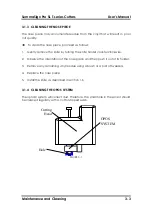

Knife calibration errors may result from the following causes (see Fig. 2-5):

•

Concentricity misalignment

. The knife tip is slightly rotated in relation to its

theoretical 0

°

angle. This error can be corrected by means of the ADJUST

ORIGIN test procedure.

•

Horizontal misalignment

. The knife tip deviates from its theoretical

longitudinal center. This error can be corrected by means of the ADJUST

LONG. test procedure.

•

Vertical misalignment

. The knife tip deviates from its theoretical lateral

center. This error can be corrected by means of the ADJUST LAT. test

procedure.

LONGITUDINAL deviation

LATERAL deviation

Theoretical centre

of the knife

Theoretical 0º

angle of the knife

ORIGIN deviation

FIGURE 2-5:

POSSIBLE KNIFE CALIBRATION GROUNDS

The calibration settings entered during the knife calibration procedure are

automatically stored in the cutter’s memory and will be maintained after power

down.