16E / 16E-H / 16E-P Spray Gun

66

MAN 96150 EN 01

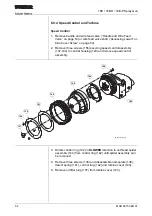

3. Install torsion spring (81) in flange of gas head subassembly (85).

The spring’s longer free end fits in the slot of the flange and the

shorter free end points downward.

4. Install spring bushing (80) on torsion spring (81).

5. Slide torsion ring (79) over spring bushing (80) and torsion spring

(81). Torsion ring is cut to fit precisely over spring and bushing.

Slide torsion ring all the way to the flange (clears pawl).

6. Slide end cap (77) onto valve core (82) so that pin in end cap

mates with slot in torsion ring (79).

7. Make sure gas valve is in closed position (handle forward).

8. Grasp torsion ring (79) firmly and apply tension to spring by rotat-

ing counterclockwise 1/2 turn.

9. Insert end cap pin (78) into end cap (77). Make sure the end cap

pin is oriented so that the hole in end cap pin will line up with the

hole in end cap. Once the end cap pin is all the way through the

valve core shaft, release the torsion ring.

10. Using a small screwdriver, align holes in end cap pin (78) and end

cap (77) and install screw (76).

11. Install torsion ring cover (75) and secure with three screws (74).

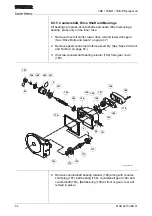

12. With spray gun inverted, install o-ring (96) in (larger) air valve port

of gas head subassembly (85).

13. Install two o-rings (97) in fuel and oxygen ports of gas head subas-

sembly (85).

14. Install o-ring (94) on air plunger (95).

16e_tortion

180º CCW

CAUTION

The valve plungers are

radiused and keyed for

orientation to mate with

the valve core. The o-

rings between the

plungers and valve core

(96, 97) are special. Do

not substitute o-rings

with non-Sulzer Metco

parts. Do not clean o-

rings with solvent. Use

only Krytox® on all o-

rings.