43

MAINTENANCE

5.10

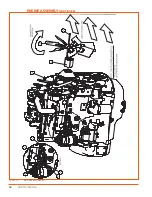

AIR INTAKE FILTER

Check daily, every 10 hours of operation or on rent return. Replace every 1,000 hours or 6 months. Replace

more frequently in dusty conditions. Empty the evacuator valve (dust boot) daily.

5.10.1 REMOVAL AND INSPECTION

1.

open the locking devices to remove air filter cover.

2.

Remove and inspect the used primary element by turning counter-clockwise to unscrew.

3.

Remove and inspect the secondary filter. The air filter elements should be thoroughly inspected for

holes by placing a lamp inside the element and carefully checking for areas of bright light passing

through the element and seal.

5.10.2 INSTALLATION

1.

Screw the new filter(s) into place by turning clockwise

2.

Place cover back on air filter andclose locking devices.

5.11

OIL RETURN LINE

Check the oil return line periodically to make sure that it does not become clogged. A clogged line results in

excessive oil consumption and oil in the service lines.

5.11.1 INSPECTION

Inspect oil return line for clogging.

5.11.2 CLEANING

If clogging is indicated, check and clean the entire line, including the orifice fitting at the compressor end,

and the siphon tube inside the separator. blowing with a reverse flow of compressor air will clean the line.

5.12

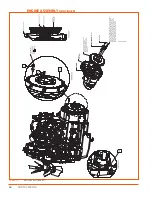

AIR/OIL SEPARATOR

Replace the air/oil separator every 2,000 hours, annually, or when differential exceeds 10 psi. The air/oil

separator employs a unitized element.

The separator element is a single piece unit, which requires replacement when it fails to remove the oil from

the discharge air. Prior to replacing the separator element be sure to check the oil return line and orifice for

plugging or restrictions.

WARNING!

Prevent separator flash or fire. Maintain the separator element in proper condition and do not allow it to

become plugged with dirt and oxidized oil; be certain that the sump lid is properly grounded to the sump

when installing a new separator. DO NOT REMOVE THE GROUNDING STAPLES IN SEPARATOR GASKET.

The combination of a build-up of dirt and oxidized oil can clog the element causing an increase in air

velocity at narrow points on the element media. Elevated temperatures at these points can result in

ignition of the fluid in the oil sump.

5.12.1 REMOVAL

1.

Relieve sump pressure to zero pressure.

2.

Disconnect oil return line. loosen fitting and pull siphon tube up out of separator.

3.

Remove service air piping from minimum pressure valve.

4.

Mark and disconnect necessary tubing at separator cover and then remove cover.

5.12.2 INSTALLATION

WARNING!

Failure to properly ground the sump lid and separator can result in the build-up of an electric charge

leading to ignition inside the sump. DO NOT REMOVE THE GROUNDING STAPLES IN SEPARATOR GASKET.

Failure to comply with this warning may cause property damage and serious bodily harm or death.

1.

Remove and replace element.

WARNING!

Lid and sump tank top must be clean to ensure proper grounding between element and tank. Make sure

grounding staples are in top and bottom gasket.

2.

Replace separator cover; tighten bolts gradually in an opposing manner until required torque is reached.

Refer to

.

Содержание D260UJD4PTOW

Страница 4: ......

Страница 6: ...vi About This Manual ...

Страница 14: ...6 Safety ...

Страница 21: ...13 Specifications 2 6 PTO SAE A DRIVE Figure 2 5 Power Take Off Auxiliary Drive Specs ...

Страница 22: ...14 Specifications ...

Страница 32: ...24 Component Description ...

Страница 44: ...36 Installation and Operation ...

Страница 58: ...50 Troubleshooting ...

Страница 125: ...117 Parts Catalog ...

Страница 134: ...NOTES ...

Страница 135: ...NOTES ...