INTERMITTENT MOVEMENT

The intermittent movement is the mechanical heart of the Pro-35. Components are machined to near-

zero tolerances, and assembly, run-in, and testing are performed by trained personnel using special tools and

fixtures. For this reason, operator adjustments performed in the field are very limited.

Factory Rebuilt intermittent movements are available under a Repair/Exchange program. Contact an

authorized Strong International Dealer for details; do not return Pro-35 intermittent movements to the factory

without first acquiring a Return Authorization Number.

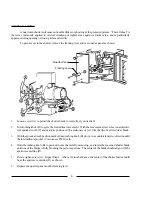

The outboard bearing assembly is accessible at the end of the intermittent sprocket shaft on the thread-

ing side of the projector. The purpose of the outboard bearing adjustment bolt (A) is to keep the ends of the

intermittent sprocket shaft (B) in contact with starwheel shaft (C), eliminating any end play at the intermittent

sprocket. Adjustment bolt (A) is the

only

field-adjustable element.

Adjust bolt (A)

fingertight only.

Correctly set, bolt (A) will keep shaft (B) in contact with shaft (C)

without end play or binding. DO NOT USE PLIERS OR ANY OTHER FASTENING TOOL.

NOTE: Possibly because of its accessibility, operators sometimes overtighten bolt (A). This action

causes DAMAGE in the bearing area (E) and applies stress on the starwheel bushing area (C) and coupling (D).

Excessive tension for prolonged periods may damage the ENTIRE MOVEMENT.

On the drive (off-operator) side of the mechanism, beneath the intermittent flywheel, the cam stop pin

and locknut assembly (F) is accessible. This assembly is considered field-adjustable only when the adjustment

is performed by QUALIFIED PERSONNEL. Consult the factory before attempting to change the setting of the

cam stop pin.

10

Содержание Ballantyne PRO-35

Страница 15: ......