Assembly as Fig 7.

One end of insurance chain is inserted in jet pipe, vibrated freely and touched to the ground. Fig.5

Connect another end conducting wire, then fix conducting wire and insurance chain on bend pipe

by screw.

Fig 7.

OPERATION:

....... .......................................................................................................................

Check:

1. Check if there is loose of sparking plug, etc.

2. Check if the air cooling opening is blocked to avoid over-heating during rotation.

3. Check if air filter is dirty to avoid bad rotation and over-waste of fuel caused by quality of incoming gas.

4. Check if the gap of the sparking plug is 0.6-.07mm.

5. Pull the starter for 2—3times to see if engine is in normal operation.

Adding fuel:

1. Adding fuel must be done at the state of the engine stop

2. The gasoline should be No.70 or No.90; the oil must be two-stroke gasolin engine oil. The mixture’s ratio

between gasoline and oil is 25-30:1. Bad quality fuel will influence the engine’s performance and destroy the

gasoline engine. While adding fuel, fuel filter must not be removed in order to avoid dirty matter coming in

fuel tank.

Adding chemical:

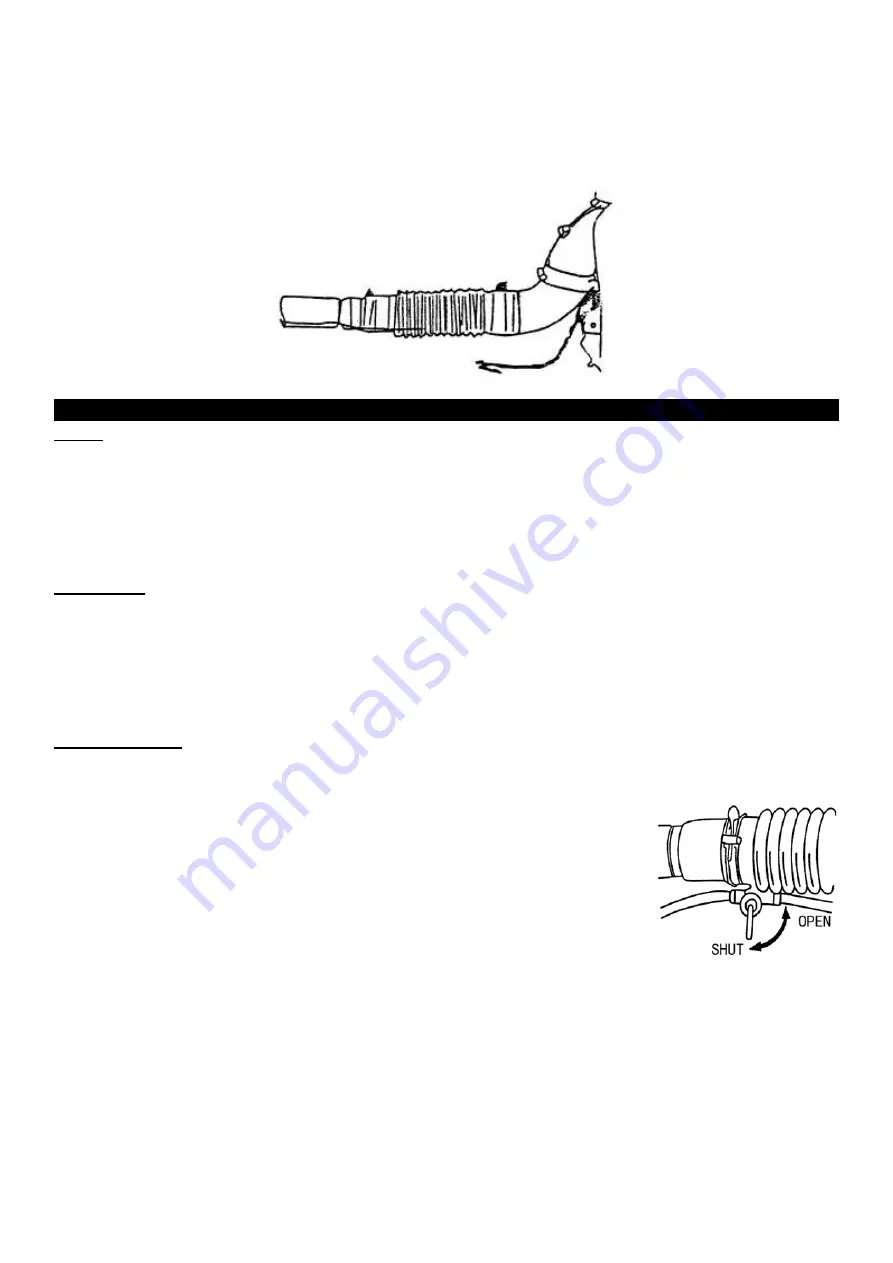

Fig 8.

1. During spraying operation, while adding chemical, the switch must be shut,

see Fig.8. During dusting operation, dusting value throttle and fuel lever should

be on the bottom position, otherwise, the machine will have chemical out.

2. As powder chemical can easily become block, so the chemicals should not be

in the chemical tank for a long time.

3. While spraying, the chemical tank lid should be turned on tightly. After adding

powder chemical, please clean the screw of chemical tank mouth, and then turn

on the lid tightly.