it off using pliers or chipping off with a chisel or scraping or grinding the finished cut as

needed and is generally only a minor inconvenience.

A combination of factors contributes to the build-up of dross. They include; material type,

material thickness, amperage used for the cut, speed of the torch across the work-piece,

condition of the torch tip, input line voltage, air pressure, etc. Generally there is an inversely

proportional relationship between output current and speed of cut. Do not use more output

current than is necessary and adjust speed of cut toward minimizing dross build-up on underside

of cut. Experiment with adjusting current and speed to minimize dross.

When dross is present on carbon steel, it is commonly referred to as either ‘high speed, slow

speed, or top dross’. Dross present on top of the plate is normally caused by too great a torch to

plate distance.

‘Top dross’ is normally very easy to remove and can often be wiped off with a welding glove.

‘Slow speed dross’ is normally present on the bottom edge of the plate. It can vary from a light

to heavy bead, but does not adhere tightly to the cut edge, and can be easily scraped off. ‘High

speed dross’ usually forms a narrow bead along the bottom of the cut edge and is very difficult

to remove. When cutting troublesome steel, it is sometimes useful to reduce the cutting speed to

produce ‘slow speed dross’. Any resultant clean up can be accomplished by scraping, not

grinding.

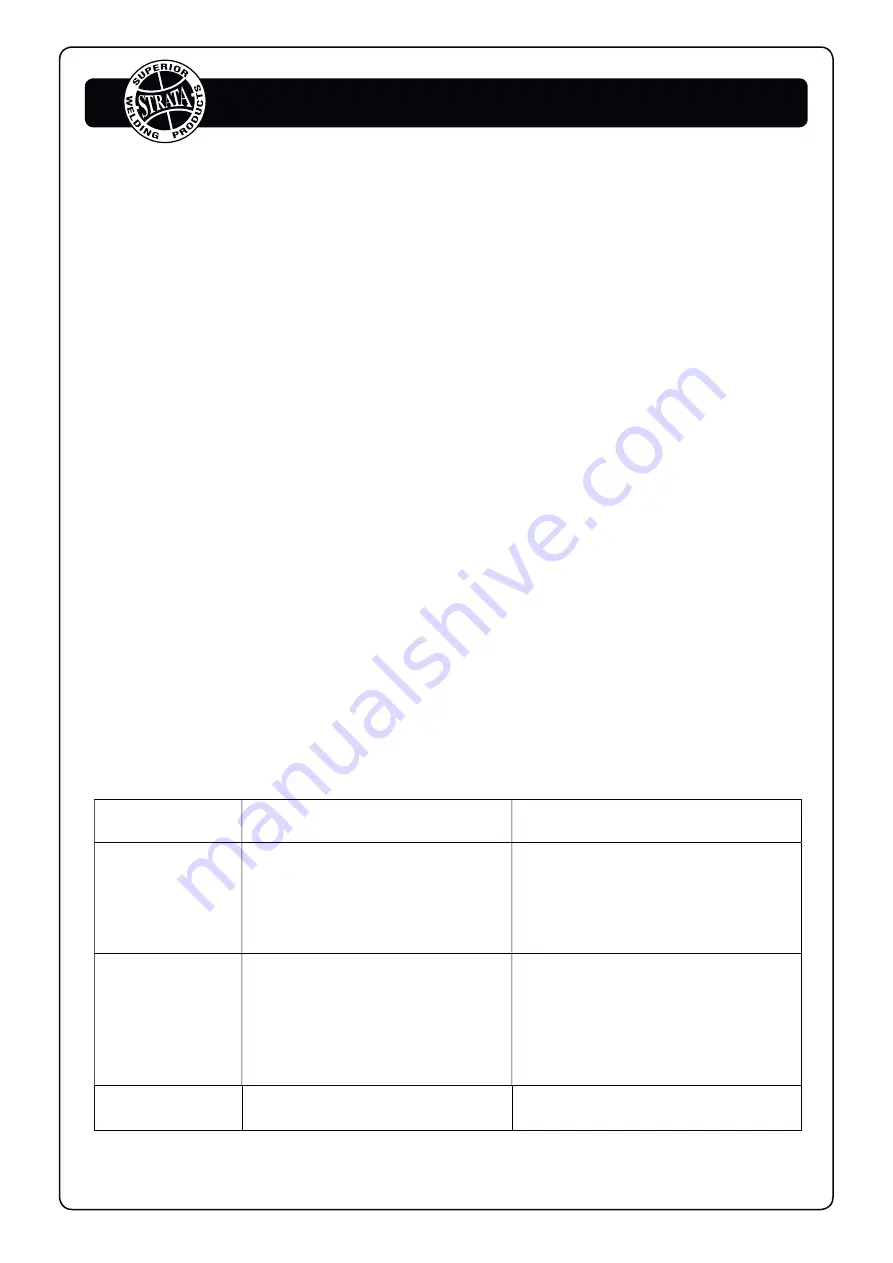

2.4 Troubleshooting

Trouble

Possible Reason

Suggested Remedy

Torch will not come

on

1.Power switch OFF

2.Air supply is not of sufficient volume or

pressure

3. Work piece ground clamp not attached.

1.Turn power switch to the ON position

2. Check air supply (60–80 PSI, 3.5cfm

required)

3. Attach to work piece or to steel table with

work piece securely clamped to table

Sparks are shooting

upward instead of

down through the

material.

1.Plasma torch is not piercing the

material

2. Torch may be too far away from the

work piece

3. Material may not be earthed properly

4. Travel speed too fast

1. Increase current

2. Decrease the distance of your torch to the

work piece

3. Check connections for proper earth

4. Reduce speed

Beginning of cut not

completely pierced

Possible earth connection problem

Check all connections

18

www.strata.co.nz

ADVANCECUT 75

Содержание ADVANCECUT 75

Страница 35: ...35 www strata co nz ADVANCECUT 75 ...