17

B. Assemble o-rings onto the spigot plungers

without

lubricant.

Then apply a thin film of sanitary lubricant

to the exposed surfaces of the o-rings.

1.

Insert the spigot assembly into the product outlet.

2.

Slide the spigot retaining clip into position.

C. Assemble the flavor bottles as follows:

1.

Replace the bottles in the flavor rack.

D. Install sani-tray and cover.

E. Replace the cup dispensers on the side of the

freezer by positioning the bracket on the dispenser

above the bracket on the side of the freezer and sliding

down.

3.7 MIX INFORMATION

It is essential to follow the mixing instructions on the

neutral base container carefully. The concentration of

ingredients in the product, which determines the "Brix"

(sugar level), is very important to the operation of the

freezer and the quality of the drink. When the proper

amount of neutral base is mixed with the proper amount of

water, the mixture should have a "Brix" reading between 11

and 13.

CAUTION

Follow proper mixing procedures. Do not pour the indi-

vidual ingredients (water or neutral base) directly in the

freezer and depend of the agitator to do the mixing. This

does not provide for adequate mixing and may cause

damage to the freezer.

Refer to the following steps for filling the freezer:

A. Follow instructions on the Slush Puppie neutral base

containers to mix neutral base with water. Then pour

into the freezer.

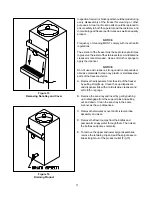

B. The product cylinder has a 10 gallon capacity, when

filled approximately 1" (2.54 cm) from the top of the

cylinder. When filling the cylinder, it is necessary to

remove all trapped air from below the divider plate.

Fill the product cylinder with mix to within 1" (2.54 cm)

from the top. Place a sanitary container under the

serving spigot and dispense small amounts of liquid by

pulling out and pushing in the spigot in a series of short

bursts. Each time the spigot is closed, bubbles will rise

to the top of the liquid in the product cylinder. When no

more bubbles rise to the top, the air trapped under the

divider plate has been removed. Pour the contents of the

container back into the product cylinder.

3.8 FREEZE DOWN AND OPERATION

A. With mixed Slush Puppie neutral base in the product

cylinder, start the freezing process by setting the

STIRRING ONLY-OFF-STIRRING & FREEZING switch

in the STIRRING & FREEZING position.

B. Although servable product can be obtained after the

freezer has been run for 1 hour, the best quality ice

crystals will develop after the freezer has been

running for several more hours.

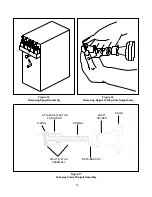

3.9 DISPENSING PRODUCT

To dispense product correctly, refer to the following steps:

A. Select the desired cup size.

B. Dispense flavor concentrate into the cup first, by

pushing the flavor pump down. Use one squirt of

flavor for small cups, two squirts for medium cups and

three squirts for large cups.

C. Place cup under and against the spigot.

D. Pull the spigot out.

E. Fill the cup. The gravity flow from the spigot will

automatically mix the flavor concentrate with the

neutral base mixture as it is dispensed.

F. When the cup is full, push the spigot in.

3.10 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm soapy

water or a mild alkaline cleanser and a soft cloth or sponge.

Do not use abrasive materials as they will mar the finish of

the freezer.

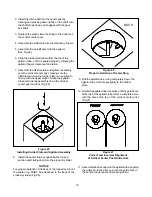

Refer to Figure 28 for all external parts of the freezer to be

cleaned.

3.11 PREVENTATIVE MAINTENANCE

It is recommended that the following maintenance sched-

ule be followed to keep the freezer clean and operating

properly.

WARNING

Hazardous Voltage

The stirring only-off-Stirring & Freezing switch must be

placed in the OFF position when disassembling for

cleaning or servicing. The freezer must be disconnected

from electrical supply before removing any access

panels. Only a qualified Service Technician may remove

access panels. Failure to disconnect power before

servicing could result in death or serious injury.

Содержание 100CA

Страница 1: ...Model 100FA 100CA 2217GA OPERATORS MANUAL Manual No 513653 Mar 2010...

Страница 2: ......

Страница 14: ...8...

Страница 26: ...20...

Страница 28: ...22...