Release 00 - 03/2018

Engine TRE 224

page 37

Workshop Manual

14. ENGINE BLOCK - External operations

14.4 Overhauling the cylinder head and valves

NOTE: These paragraphs describe all the

operations for checking and overhauling the

cylinder head;

it is left to the operator to assess the advisabi-

lity of performing all the operations described

or only part of them, depending on the type

of engine problems encountered.

1 - Dismount the cylinder head

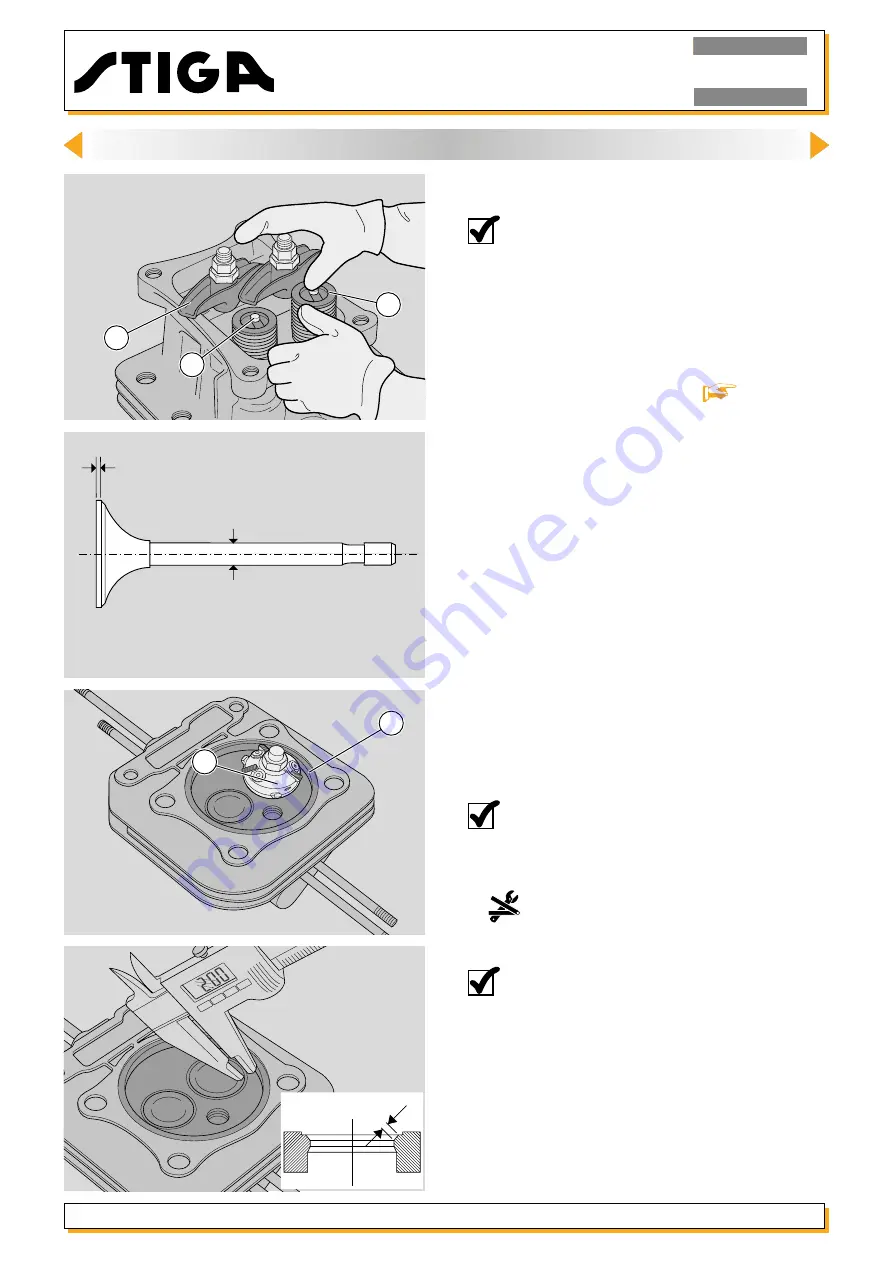

2 - Move the rocker arms (17); press down the spring

seal cap (18) and move it sideways to remove from

the valve stem (19).

IMPORTANT - The inlet and exhaust valves are diffe-

rent from each other and can be identified by the

marking «IN» (YI - inlet) and «EX» (YE - exhaust), on

the valve head.

3 - Use an emery cloth to remove all incrustations

from the valve head and check the thickness of the

rim (A); the valve must be replaced if the margin (A)

is less than 0,5 mm (inlet - IN/YI) or 0,5 mm (exhaust

- EX/YE) or if it shows signs of burning.

4 - Check the diameter of stem (B) in several points

and replace the valve if it is less than the following,

even if only in one point:

5,32 mm (inlet - IN/YI)

5,27 mm (exhaust - EX/YE)

NOTE: The valve seats must be ground by

hand, using a special grinding tool with an

angle of 45°.

5 -

Insert the pin (20) in the cylinder head valve

uide and then the grinding tool (21).

NOTE: Grinding must be done taking care to

remove as little material as possible.

6 - Use a caliper gauge to check the depth of the

valve seat (C), which must be 2,0 mm; the cylinder

head must be replaced if a greater value is mea-

sured.

A

B

18

17

YI

C

20

21

19

<< BACK >>

INDEX

Содержание TRE 224

Страница 2: ......

Страница 55: ...Release 00 03 2018 Engine TRE 224 page 55 Workshop Manual BACK INDEX ...