EN - 7

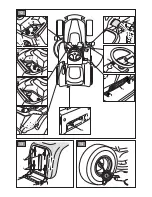

4.2 STEERING WHEEL ASSEMBLY

1.

Put the machine on a flat surface

and straighten the front wheels.

2.

Link the connector (Fig. 3.A) to the hour

meter (Fig. 3.B) fixed in the rear part

of the dashboard cover (Fig. 3.C).

3.

Mount the hub (

fig. 4.A)

on the shaft

(

fig. 4.B)

, making sure that the plug (

fig. 4.C)

is correctly fitted into the hub seat.

4.

Fit the dashboard cover (

fig. 4.D)

clicking

the seven fasteners into place.

5.

Fit the steering wheel (

fig. 4.E)

onto

the hub (

fig. 4.A)

with the spokes

directed towards the seat.

6.

Fit the spacer (

fig. 4.F

) and fasten the

steering wheel in place using the screws

supplied (

fig. 4.G)

in the indicated order.

7.

Fit the steering wheel cover (

fig. 4.H)

by clicking the fasteners into place.

4.3 SEAT ASSEMBLY

Fit the seat (fig. 5.A) onto the plate (fig. 5.B) using

the screws (fig. 5.C).

4.4 MOUNTING AND CONNECTING

THE BATTERY

The battery (fig. 6.A) is housed under the seat

and secured by a spring (fig. 6.B).

1.

First connect the red wire (

fig. 6.C)

to

the positive pole (+) and then the black

wire (

fig. 6.D)

to the negative pole (–),

using the screws supplied as shown.

2.

Apply silicone grease to the terminals

and check that the protective cap for

the red wire (fig. 6.E) is in place.

IMPORTANT

Always fully charge the battery

according to the instructions in the battery book

-

let.

IMPORTANT

To prevent the safety device in

the electronic circuit board from cutting in, never

start the engine until the battery is fully charged!

4.5 MOUNTING THE REAR BUMPER

1.

1a.

For type "l" bumpers only -

Mount the front

bumper (fig. 7.A) on the bottom of the frame

(fig. 7.B) using the four screws (fig. 7.C).

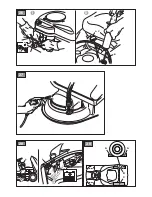

1b.

For type “II” bumpers only

1.

Fit the two brackets

(fig. 8.A)

and

(fig.

8.B) to the bottom of the frame

(fig. 8.C)

following the direction of assembly

indicated in the figure: R= right; L= left.

2.

fully tighten the screws (

fig. 8.D)

.

3.

Attach the front bumper (fig. 8.E) to the

brackets (fig. 8.A) and

(

fig. 8.B) using

the screws (

fig. 8.F) and nuts

(

fig. 8.G).

4.6

MOUNTING THE CUTTING-

MEANS ASSEMBLY SIDE

REINFORCEMENTS

(IF FORESEEN).

Complete the mounting of the cutting-means

assembly by fitting the side reinforcements

on the cutting-means assembly profile

using the screws supplied (fig. 9)

4.7 MOUNTING THE SIDE GUARDS

OF THE CUTTING DEVICE

ASSEMBLY (IF ANY)

Mount the safety panels (fig. 10.A)

using the screws (fig. 10.B) and

nuts (fig. 10.C) supplied..

4.8 SIDE DISCHARGE CHUTE ASSEMBLY

1.

From the inside of the side discharge chute

(fig. 11.A), fit the spring (fig. 11.B) by

inserting the terminal (fig. 11.B.1) into the

hole and turning it so that both the spring

(fig. 11.B) and the terminal (fig. 11.B.2)

are securely positioned in their seatings.

2.

Position the side discharge chute (fig.

11.A) in line with the cutting-means

assembly brackets (fig. 11.C). Using a

screwdriver, turn the second terminal (fig.

11.B.2) of the spring (fig. 11.B) to bring

it outside the side discharge chute.

3.

Fit the pin

(fig. 11.D)

in the holes on the

brackets

(fig. 11.C)

and on the side discharge

chute, so that it passes through the coils

of the spring

(fig. 11.B)

and the drilled end

comes out of the inner most bracket.

4.

Insert the cotter pin

(fig. 11.E)

in the pin

(fig. 11.D)

hole

(fig. 11.D.1)

and rotate the

pin until it is possible to bend the two ends

(fig. 11.E.1)

of the cotter pin, (with the aid

of a pair of pliers), so it cannot slide out

and cause the pin to fall out

(fig. 11.D)

.

Check that the spring works

correctly and keep the side discharge

chute securely lowered. Make sure that

the pin is fitted properly to prevent

it from falling out accidentally.

IMPORTANT

For models with optional side

unloading: make sure that the side unloading

guard (Fig. 15.A) is lowered and locked by the

safety lever (Fig. 15.B).

Содержание SDNSL 108 Hydro

Страница 2: ......

Страница 3: ...ITALIANO Istruzioni Originali IT ENGLISH Translation of the original instruction EN ...

Страница 5: ...5 3 A B C D E A F G H A A B C 4 B C C A 6 A B C D E ...

Страница 6: ...7 I II A C C B OK NO A B C D D E F F G G 8 9 ...

Страница 7: ...10 A B B C C 11 B 2 A C B 2 A D C B D 1 E D E 1 A B B 1 B B ...

Страница 8: ...12 J A B C D E E 1 F G H I L E F II I 13 14 A A ...

Страница 9: ...15 A B 16 B A 17 A H H 30 mm H 10 mm H 20 mm H 0 mm A C B D 18 max 10 17 19 A 20 1 3 21 A B ...

Страница 10: ...22 A 23 24 25 B C A ...

Страница 11: ...27 A B C A B C A 26 I II A A 28 29 A A B C ...

Страница 12: ...A 110 mm 30 31 32 33 B A C C 34 A D B C 35 A B A A B C ...

Страница 13: ...36 A A 37 38 B C D A2 ...

Страница 38: ...STIGA S p A Via del Lavoro 6 31033 Castelfranco Veneto TV ITALY Type s n Art N stiga com ...