12

electrIcal data

General

Check the boiler model and rating plate information against the

characteristics of the branch circuit electrical supply. Do not connect

the boiler to an improper source of electricity.

Voltage applied to the boiler should not vary more than + 5% to -10%

of the model and rating plate marking for satisfactory operation.

Do not energize the branch circuit for any reason before the boiler is

filled with water. Doing so may cause the heating elements to burn

out. Such damage is not covered under the terms of the warranty.

The branch circuit is connected to the block through an opening

provided on top of the boiler.

The boiler should be connected to a separate, grounded, branch

circuit with overcurrent protection and disconnect switch. These are

part of the electrical supply system not components of the boiler,

as such they are obtained locally. The boiler should be grounded in

accordance with national and local codes.

Branch cIrcuIt

The branch circuit wire size should be established through reference

to the National Electrical Code or other locally approved source in

conjunction with boiler amperage rating. Branch circuit wiring which

connects to the boiler terminal block should be temperature rated

at 75°C. For convenience, portions of the wire size tables from the

Code are reproduced here. It is suggested the electrician size the

branch circuit at 125 percent of the boiler rating and further increase

wire size as necessary to compensate for voltage drop in long runs.

Branch circuit voltage drop should not exceed 3% at the boiler.

calculatInG aMperaGe/

oVercurrent protectIon

The boiler is factory wired for connection to three wire single-phase

or three and four wire three-phase branch circuits. In addition, a

ground conductor may be required.

A diagram of the wiring “as built” is furnished with the boiler for the

electrician’s use. An amperage table is on pages 7 & 12 of this manual.

The boiler model and rating plate provides full load amperage data.

Typical or Standard wiring diagrams are provided on pages 13 & 14

of this manual.

The rating of the overcurrent protection should be computed on the

basis of 125 percent of the total connected load amperage. Where the

standard ratings and settings do not correspond with this computation,

the next higher standard rating or setting should be selected.

BoIler cIrcuIts

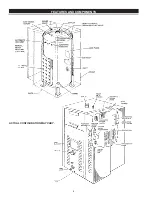

The boiler’s electrical components are pictured and identified on

page 8. The model and rating plate illustration on page 9 identifies the

electrical characteristics. Basically, there are two electrical circuits:

• The control circuit, where the temperature control directly or

indirectly operates the contactor coils.

• The power circuit, which is operated by the control circuit, carries

the electrical load of the heating elements.

The following describes the circuits and includes typical wiring diagrams.

All circuits are designed for 60 or 50 Hertz alternating current.

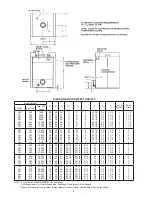

Refer to ELECTRICAL CONFIGURATION TABLE, below, and wiring

diagram provided with your boiler before completing connections to

electrical supply.

NOTE: Wiring diagrams in this manual are typical examples. The

specific wiring diagram “as built” for your boiler is typically attached to

the “inner side” of the control panel.

control cIrcuIt

All control circuits are operated on single-phase 120V. A transformer

is used in the control circuit.

Control circuit wiring is 14 Awg, THHN or THWN type, rated 600

volts, 105°C.

Seperate instructional literature is provided with the boiler for step control.

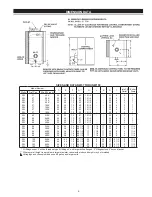

portion of table 310-16

Allowable Ampacities of Insulated

Copper Conductors

Not more than three conductors in

raceway or cable or direct burial

(based on ambient temperature of

30°C, 86°F.)

portion of table 310-16

Allowable Ampacities of Insulated

Aluminum and Copper-Clad

Aluminum Conductors

Not more than three conductors in

raceway or cable or direct burial

(based on ambient temperature of

30°C, 86°F.)

size

temperature

rating of

conductor. see

table 310-13 in

code

size

temperature

rating of

conductor. see

table 310-13 in

code

awG

McM

75°c (167°f)

types rh,

rhw, ruh (14-

2), thw, thwn,

Xhhw, use

awG

McM

75°c (167°f)

types rh,

rhw, ruh (12-

2), thw, thwn,

Xhhw, use

18

16

14

12

10

8

- - - - -

- - - - -

15

20

30

45

12

10

8

6

4

3

15

25

40

50

65

75

6

4

3

2

1

1/0

65

85

100

115

130

150

2

1

1/0

2/0

3/0

4/0

90

100

120

135

155

180

2/0

3/0

4/0

250

300

350

175

200

230

255

285

310

250

300

350

400

500

600

205

230

250

270

310

340

400

500

600

700

750

800

900

335

380

420

460

475

490

520

700

750

800

900

1000

1250

1500

375

385

395

425

445

485

520

1000

1250

1500

1750

2000

545

590

625

650

665

1750

2000

545

560

These capacites relate only to conductors

described in Table 310-13 in Code.

For ambient temperatures over 30°C, see

Correction Factors, Note 13 in Code