6. Do not leave your tool unattended while switched on.

7. Do not use or store your tool in damp or wet conditions.

USEFUL HINTS & TIPS

1. Your rotary tool will become warm after prolonged use and so must be switched off and allowed

to cool down.

2. To ensure smooth running, the spindle should be oiled periodically.

3. Do not apply too much radial pressure to the accessory bits while polishing, cleaning, sanding or

grinding. By doing this you will put a strain on the spindle and adversely affect the precision of the

tool.

4. Always work with a sensitive touch so as not to impede the efficiency of your mini tool.

5. When drilling metal, always mark the drilling point with a centre punch first, so that your rotary

tool does not slip.

6. Always ensure that you have maximum contact between the accessory shaft and the collet chuck.

7. Vary the speed on the tool for the work in hand, eg. Low speed for polishing & cleaning and high

speed for engraving

PLACING ACCESSORIES INTO THE TOOL

Always switch the tool off first. Hold the locking button at the front of the tool down and undo the

collet chuck (anti-clockwise). Insert the collet that matches the shaft size of the accessory to be

used. Place the collet nut over the collet and then insert the accessory shaft into the collet chuck

ensuring maximum shaft contact. Then tighten up the collet nut. (DO NOT USE PLIERS).

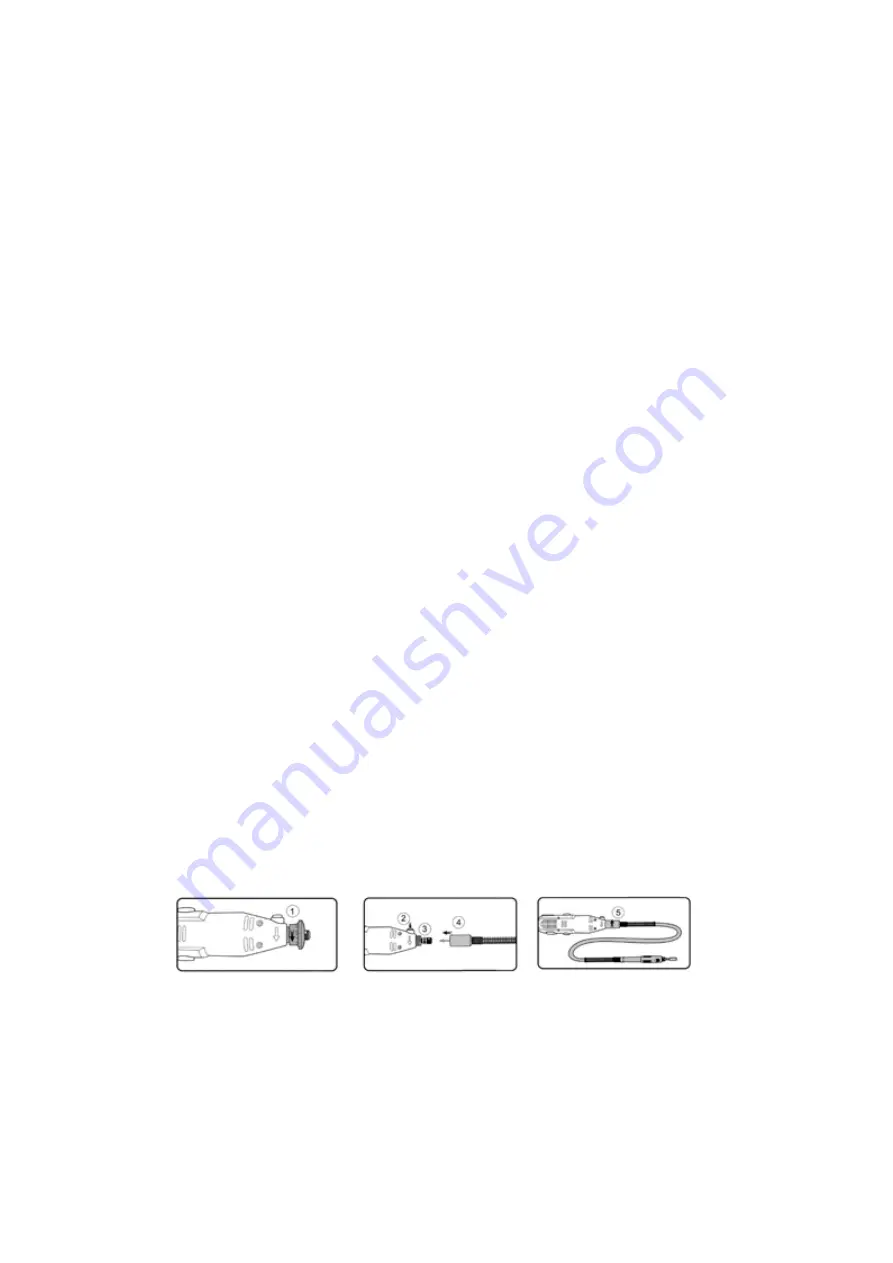

FLEXYDRIVE ASSEMBLY

Remove the front ring nut from the tool by turning in an anti-clockwise direction. Partially unscrew

the blocking ring nut from the spindle . Partially extract the internal transmission cable from the

flexydrive. Insert the flexydrive transmission cable into the spindle of the tool pushing it in as far as

possible. Keep the spindle block button pressed in and screw the spindle blocking ring nut turning it

in a clockwise direction. Tighten using the spanner for this purpose. Screw the threaded end of the

flexydrive onto the body of the tool and tighten, screwing in a clockwise direction

CHANGING THE INSERT AND ACCESSORIES ON THE FLEXYDRIVE

To change the insert or to install accessories on the flexydrive, follow the same general procedure

for insert change and for accessory assembly on the attachment. To block the spindle, turn it until

the hole in the shaft is in line with the hole on the handle of the flexydrive Insert a 1/8” drill bit in

the aligned holes to block the shaft.

Содержание red line MG 1440

Страница 11: ......