– 8 –

1.

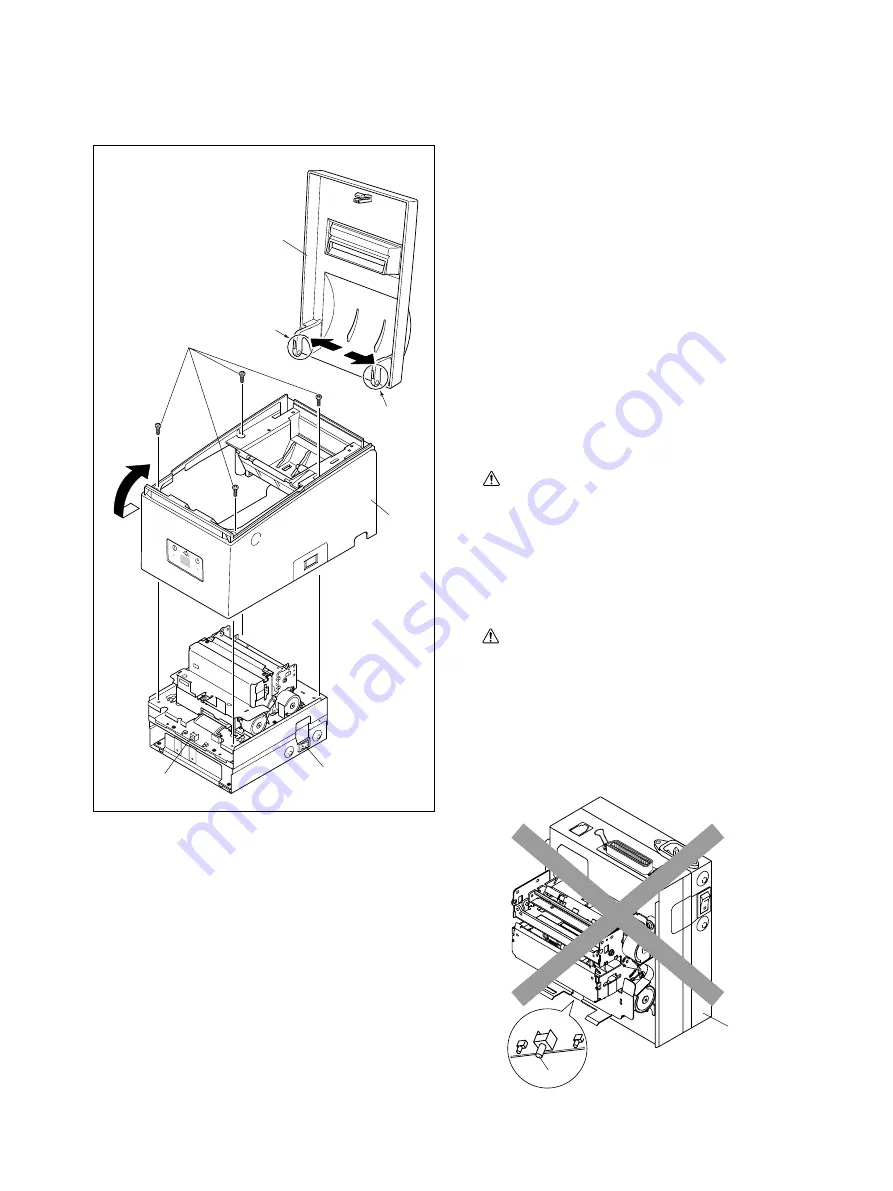

Case Unit

(1)

Turn off the power switch

1

, disconnect the power

cord from the wall outlet.

(2)

Lift up the front of printer cover

2

and open printer

cover.

(3)

Spread to the outside at points A (left / right) of printer

cover

2

and remove printer cover.

(4)

Remove

•

Four screws

3

•

Case unit

4

Lift the case unit

4

.

At this time, avoid the power switch

1

.

Caution 1:

When removing the case unit

4

, rotate it while pulling

it toward so that it does not hit the FEED switch

5

.

It is possible to damage the FEED switch if a strong

force is applied to it.

When remounting the case unit, be careful not to hit the

FEED switch

5

.

Caution 2:

After removing or before remounting the case unit,

absolutely never set the mechanical unit

6

with the

FEED switch facing downward.

The FEED switch can be pulled from the frame cause

a strong force to be applied to it which can result in its

becoming damaged.

ER

RO

R

ER

RO

R

PO

W

ER

PO

W

ER

FE

ED

FE

ED

1

5

3

2

4

A

A

6

5

Содержание SP500 Series

Страница 1: ...DOT MATRIX PRINTER SP500 Series TECHNICAL MANUAL FOURTH EDITION ...

Страница 24: ... 21 Fig 3 2 Lubricated Areas B C D E A A F G F G B C D E 1 7 6 8 0 A D A 2 3 9 5 4 B C C ...

Страница 25: ... 22 Fig 3 3 Screw Locking a b c d e e ...

Страница 42: ... 39 Main Logic Board Parallel Interface 3 4 ...

Страница 43: ... 40 Main Logic Board Parallel Interface 4 4 ...

Страница 44: ... 41 5 2 Component Layout ...

Страница 51: ... 48 Main Logic Board RS 232C Interface 3 4 ...

Страница 52: ... 49 Main Logic Board RS 232C Interface 4 4 ...

Страница 53: ... 50 6 2 Component Layout ...

Страница 60: ... 57 Main Logic Board USB Ethernet Wireless LAN Interface 3 4 ...

Страница 61: ... 58 Main Logic Board USB Ethernet Wireless LAN Interface 4 4 ...

Страница 62: ... 59 UPC358 7 2 Component Layout ...

Страница 67: ... 64 8 Power Supply Unit 8 1 Circuit Diagram ...

Страница 68: ... 65 8 2 Component Layout ...

Страница 71: ... 68 9 USB Interface Board 9 1 Circuit Diagram ...