8 | TA54 User Manual

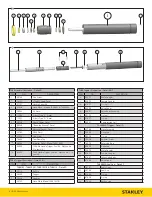

What is TA54 Hydraulic Tamper?

TA54 is a hand held hydraulic tool used to compact soil around utility poles,

signs and fence posts. TA54 requires an external hydraulic power supply

capable of supplying 3-9 GPM @ 1000-2000 PSI.

Specifications

Pressure

1000-2000 PSI (69-138 BAR)

Flow

3-9 GPM (11-34 LPM)

Hydraulic Circuit Type

Open Center

Max. Relief Pressure

2250 PSI (155 BAR)

Recommended Back

Pressure

250 PSI (17 BAR) or less

Couplers

3/8 Inch NPT Flush Face

Port Size

1/2 Inch SAE O-ring

Min. Hose Pressure Rating

2500 PSI (172 BAR)

Max. Hydraulic Oil Temp.

140°F (60°C)

Tool Weight

25 Lbs.

Tool Size

71 Inches x 4 Inches x 4 Inches

HTMA/EHTMA Category

Type I & II, Category C & D

Sound & Vibration Declaration

Measured A-Weighted sound power

108.38 dBA

Measured A-Weighted Sound Pressure

97.39 dBA

Values determined according to noise test code given in ISO 15744, 11203

and 3744. Test conducted by independent notified body to comply with

2000/14/EC:2006.

Trigger Handle

Measured Vibration Emission Value: 3-Axis

58.9 m/sec²

Uncertainty

13.2 m/sec²

Support Handle

Measured Vibration Emission Value: 3-Axis

59.6 m/sec²

Uncertainty

13.2 m/sec²

Values determined according to ISO 28927-6

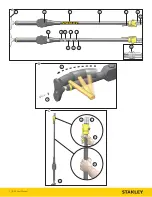

Parts of a TA54 - Detail A

1

Tamper Shoe

2

Serial Number & Year of Manufacture

3

STANLEY Logo Decal

4

Handle Tube

5

Trigger

6

Female Coupler

7

Male Coupler

8

Tool Name Tag

9

GPM Decal

10

Electrical Danger Decal

11

“Read the Manual” Decal

12

Sound Power Decal

13

Circuit Type “D” Decal

14

Circuit Type “C” Decal

15

CE Decal

16

Trigger - Model TA54603A

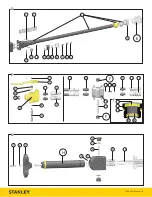

Tool Setup - Detail B

Do not install or change tool accessories while the

hydraulic power source is connected. Accidental

engagement of the tool can cause serious injury.

Disconnect the hydraulic power source before installing

or changing accessories.

1. Disconnect the tool from the hydraulic power source.

Install Tamper Shoe

Note: TT54 ships with a tamper shoe installed.

2. Lay TT54 on a workbench.

3. Remove the retaining bolt and washer from the bottom of the tamper

shoe.

4. Using a soft faced mallet, lightly strike the top of the shoe to remove it

from the piston.

5. Fit the new tamper shoe onto the piston.

6. Thread the retaining bolt through the tamper shoe and into the piston.

7. Torque to 41 Ft. Lbs. (54 Nm). Ensure the tamper shoe is locked into

place.

Never operate the tool unless the tamper shoe is

retained. Shoe can become a high velocity projectile.

Secure the shoe as shown in this manual.

Tool Operation - Detail C

Connect to a Hydraulic Power Source

1. Using a calibrated flow and pressure gauge, check the output of the

hydraulic power source. Ensure it matches the flow and pressure in

“Specifications” on page 8. Hydraulic fluid must be 50°F or above.

Preheat if necessary.

2. Ensure that the hydraulic power source is equipped with a relief valve

set to open at the maximum relief pressure. See “Specifications” on

page 8.

3. Wipe hose couplers with a clean, lint free cloth.

4. Connect the return hose to the male coupler.

5. Connect the pressure hose to the female coupler.

6. Ensure couplers are undamaged, properly connected and are tight.

Note: TA54 will rise quickly when hydraulic power is first turned on. Do not

stand over, or place any part of your body, over the tamper.

7. Power up the hydraulic power source.

Using the Tool

8. Place your dominant hand on the handle tube, over the trigger.

9. Place you non-dominant hand lower on the handle tube, where you

can best control the tool.

10. Place the tamper shoe on the ground to be compacted, at a 90° angle.

Apply down pressure.

Note: Maintain a balanced body position and secure footing while operating

tool. Do not put hands, feet or other body parts under the tamping shoe.

Personal injury could result.

11. Slowly squeeze the trigger to start compacting. Squeeze harder for fast

speed operation. Guide the tamper using both hands on the handle

tube.

Note: Hold the tool correctly and be ready to counteract normal or sudden

movements. Have both hands available.

12. Release the trigger to immediately stop the tool.

Note: If you encounter a breakdown or the tool stops for any reason, release

the trigger and power down the hydraulic power source.

Содержание TA54

Страница 2: ...2 TA54 User Manual 1 2 3 5 6 7 8 9 10 11 12 13 14 15 16 4 A B 3 4 C 4 5 8 10 9...

Страница 10: ......

Страница 11: ......