10

ENGLISH

(Original instructions)

Installing and Removing the Battery Pack from

the tool

Warning!

Make certain the lock-off button is engaged to

prevent switch actuation before removing or installing battery.

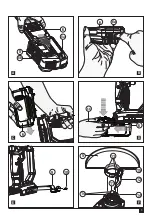

To install battery pack (Fig. C)

u

Insert battery pack firmly into tool until an audible click is

heard as shown in figure C. Ensure battery pack is fully

seated and fully latched into position.

To remove battery pack (Fig. D)

u

Depress the battery release button (6b) as shown in

figure D and pull battery pack out of tool.

Storage hook (Optional extra) (Fig. E)

Warning!

To reduce the risk of serious personal injury,

place the forward/reverse button in the lock-off position or

turn tool off and disconnect battery pack before making

any adjustments or removing/installing attachments or

accessories. An accidental start-up can cause injury.

Warning!

To reduce the risk of serious personal injury, ensure

the screw (10) holding the storage hook is secure.

Note: When attaching or replacing the storage hook (9),

use only the screw (10) that is provided. Be sure to securely

tighten the screw.

If the hook is not desired at all, it can be removed from

the tool.

To move the storage hook, remove the screw (10) that holds

the storage hook (9) in place.

Note: Various trackwall hooks and storage configurations

are available.

Please visit our website www.stanley.eu/3 for

further information.

Fitting and removing the guard (Fig. F, G)

The tool is supplied with a guard intended for grinding

purposes. Ensure you use the correct guard specific for the

intended operation. If the unit is intended to perform cutting

off operations, a guard (16, Fig G) specific for this operation

must be fitted .

Fitting

u

Place the tool on a table, with the spindle (11) facing up.

u

Release the clamping lock (12) and hold the guard (5)

over the tool as shown.

u

Align the lugs (13) with the notches (14).

u

Press the guard down and rotate it counterclockwise to

the required position.

u

Fasten the clamping lock (12) to secure the guard to

the tool.

u

If required, tighten the screw (15) to increase the

clamping force.

Removing

u

Release the clamping lock (12).

u

Rotate the guard clockwise to align the lugs (13) with the

notches (14).

u

Remove the guard from the tool.

Warning!

Never use the tool without the guard.

Switching on and off

u

To switch on, slide the lock off switch (1) forward then

press and hold the trigger switch (2).

u

To switch off, release the trigger switch (2).

Warning!

Do not switch the tool on or off while under load.

Warning!

Always slide the lock off switch (1) backwards to the

locked position when the tool is not in use.

Hints for optimum use

u

Firmly hold the tool with one hand around the side handle

and the other hand around the main handle.

Surface grinding with grinding wheels

u

Allow the tool to reach full speed before touching the tool

to the work surface.

u

Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Grinding rate is greatest

when the tool operates at high speed.

u

Maintain a 20˚ to 30˚ angle between the tool and

work surface.

u

Continuously move the tool in a forward and back motion

to avoid creating gouges in the work surface.

u

Remove the tool from work surface before turning tool off.

Allow the tool to stop rotating before laying it down.

Edge grinding with grinding wheels

Wheels used for cutting and edge grinding may break or kick

back if they bend or twist while the tool is being used to do

cut-off work or deep grinding. To reduce the risk of serious

injury, limit the use of these wheels with a standard

Type 27 guard to shallow cutting and notching (less than

13 mm in depth). The open side of the guard must be

positioned away from the operator. For deeper cutting with a

Type 1 cut-off wheel, use a closed Type 1 guard.

u

Allow the tool to reach full speed before touching the tool

to the work surface.

u

Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Grinding rate is greatest

when the tool operates at high speed.

u

Position yourself so that the open-underside of the wheel

is facing away from you.

u

Once a cut is begun and a notch is established in the

workpiece, do not change the angle of the cut. Changing

the angle will cause the wheel to bend and may cause

wheel breakage. Edge grinding wheels are not designed

to withstand side pressures caused by bending.

Содержание Fatmax SFMCG400

Страница 1: ...www stanley eu SFMCG400 2 1 4 5 3 7 6 ...

Страница 2: ...2 English original instructions 4 ...

Страница 3: ...3 6 8 8b 8a A 6 6a B 6 C 6 6b 9 10 D E 5 14 13 15 12 14 11 F ...