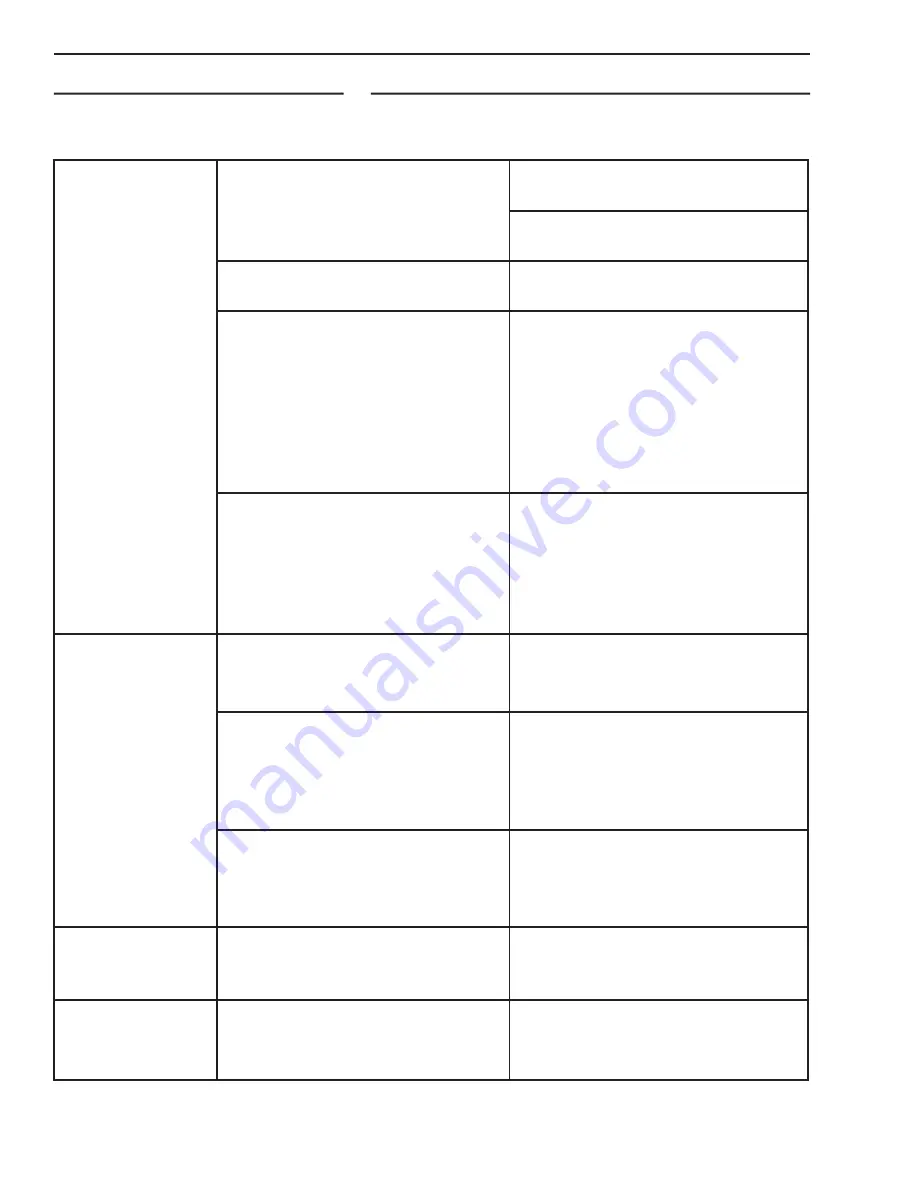

12

Fluid Restriction in hose or valve.

Excess back pressure.

continued

Troubleshooting

Low drilling torque.

continued

Fluid not warmed-up. Preheat

system.

Trigger mechanism blocked.

Do not separate modules. Clean

trigger area. Adjust trigger.

Tool runs too fast.

Priority flow control valve is

malfunctioning.

See your authorized service dealer

for replacement.

Symptom

Possible Cause

Solution

Trigger operation

erratic.

Control difficult.

Hydraulic flow reversed.

Correct the tool hoses,

IN

and

OUT

per instructions and if the power

supply valve is reversible, reconnect

the tool return hose to the oil cooler

or to the filter directly.

Incorrect hydraulic flow.

Check that hydraulic power source

is not producing over 13.2 / 50 lpm

at 950-2000 psi / 66-149 bar.

Priority valve faulty.

Do not separate modules. Remove

inspect and replace priority valve if

necessary. See your authorized

service dealer for replacement.

Hoses too long for hose I.D. Use

shorter hose.

Flow reversed through hoses.

Correct the power source control

valve position. Prevent reverse flow

by using only one port from the

valve for pressure, the return tool

hose to the cooler and the filter line.

Correct the quick-disconnect male/

female routing per instructions and

the arrows on the fittings.

Too low slip clutch torque.

Inspect and replace slip clutch

washers if necessary. Set torque to

20±1,5

Nm, 15±1 lbf.ft.

Do not overload drill to avoid wear

of slip clutch.

See your

authorized service dealer for repair.

Motor capscrews loose.

Tighten to recommended torque (10

Nm = 7, 5 lbf.ft).

Fluid leak at air

gap between motor

and valve housing.

continued