5

INSTALLATION

Installation of filter should only be done by qualified, licensed personnel.

Filter mount must:

• Provide weather and freezing protection.

• Provide space and lighting for easy access for routine maintenance. (See

Figure 1 and Table II, Page 6, for space requirements.)

• Be on a reasonably level surface and provide adequate drainage.

• Be as close to pool as possible to reduce line loss from pipe friction.

Piping:

• Piping must conform to local/state plumbing and sanitary codes.

• Use Teflon tape or Plasto-Joint Stik' on all male connections of plastic pipe

and fittings.

DO NOT use pipe compounds on plastic pipe; it will cause the

pipe to crack. Do not use sealant on unions—assemble them dry and hand

tight.

• Support pipe independently to prevent strains on filter or valve.

• Use 2” (51mm) pipe to reduce pressure losses as much as possible.

NOTICE:

Filter may be located away from pool, but for adequate flow larger

pipe may be needed. Check local codes for remote installation.

• Fittings restrict flow; for best efficiency use fewest possible fittings.

• Keep piping tight and free of leaks: pump suction line leaks may cause

trapped air in filter tank or loss of prime at pump; pump discharge line leaks

may show up as dampness or jets of water.

•

NOTICE:

Overtightening can crack filter ports.

Valves:

• A check valve installed ahead of filter inlet will prevent contaminants from

draining back into pool.

• A check valve installed between filter and heater will prevent hot water

from backing up into filter and deforming internal components.

• Install Sta-Rite Two Position Slide Valve or Multiport Selector Valve with fil-

ter. See Table I.

• Filter ports and valve ports are furnished with union connections.

DO NOT use pipe sealants on union collar (nut).

• Use care before assembly not to damage union sealing surfaces or O Ring.

• To allow recirculation during precoat (if precoat pot is used), install a recir-

culation line with shut-off between pad return line and pump suction.

Electrical

• All wiring, grounding and bonding of associated equipment must meet local

and/or National Electrical Code standards.

1

Lake Chemical Co., Chicago, IL

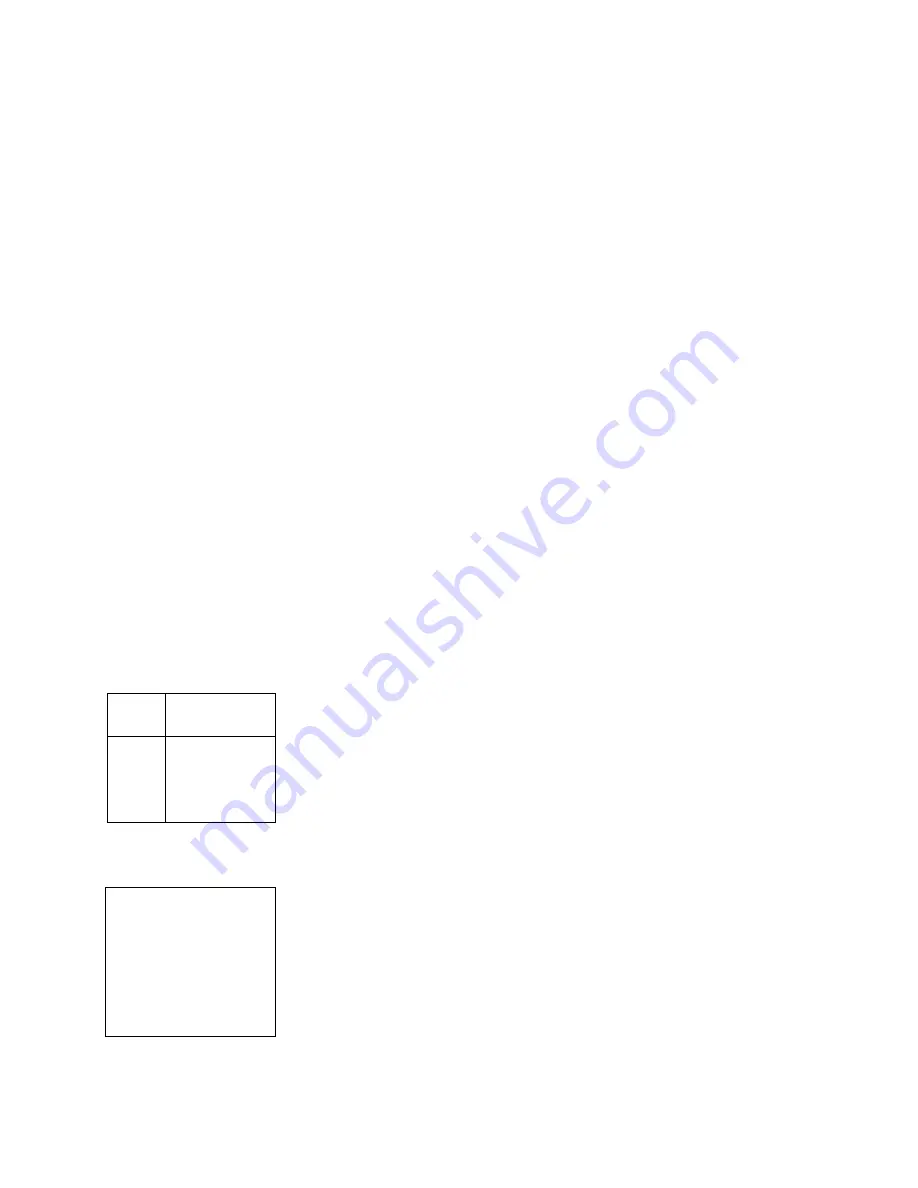

Port

Part

Size

Number

Multi-port

2"

18201-0200*

Plastic Slide

2"

WC212-134P*

TABLE I - Sta-Rite valves for

use with DE filters

NOTICE:

Use of valves

other than those listed

above could cause

reversed water flow

through filters and

damage to internal fil-

ter components.

* Recommended for best energy

conservation.