5

INSTALLATION

The TankJet 80 or TankJet 80H is easy to install as it has a

single 1-1/2" female pipe thread connection (NPT or BSPT). It

may be installed on a tripod, suspended from a pipe, manhole

cover, etc., but the unit must be VERTICAL. In all installations

a suitable strainer should be used (such as a 20 Mesh “Y”

strainer) to prevent dirt or scale from clogging the waterways

or openings.

WARNING: In closed tanks, provisions should be made for

adequate venting during operation to allow the escape of

any gases or volatile vapors which may be produced during

operation.

OPERATION

To start the unit, turn on the fluid. An in-line valve is required

for a slow build-up of liquid pressure in the unit to prevent

“water hammer”. To stop the unit, turn off the liquid. The unit

should always be handled with caution. Make sure nozzles

are screwed on the body and hold TankJet 80 by its nozzle not

the body. The nozzle hub will rotate freely and bevel gears can

pinch skin and/or fingers. If the unit is dropped or maltreated

it may cause internal damage to the drive assembly, which in

turn can affect the performance of the unit.

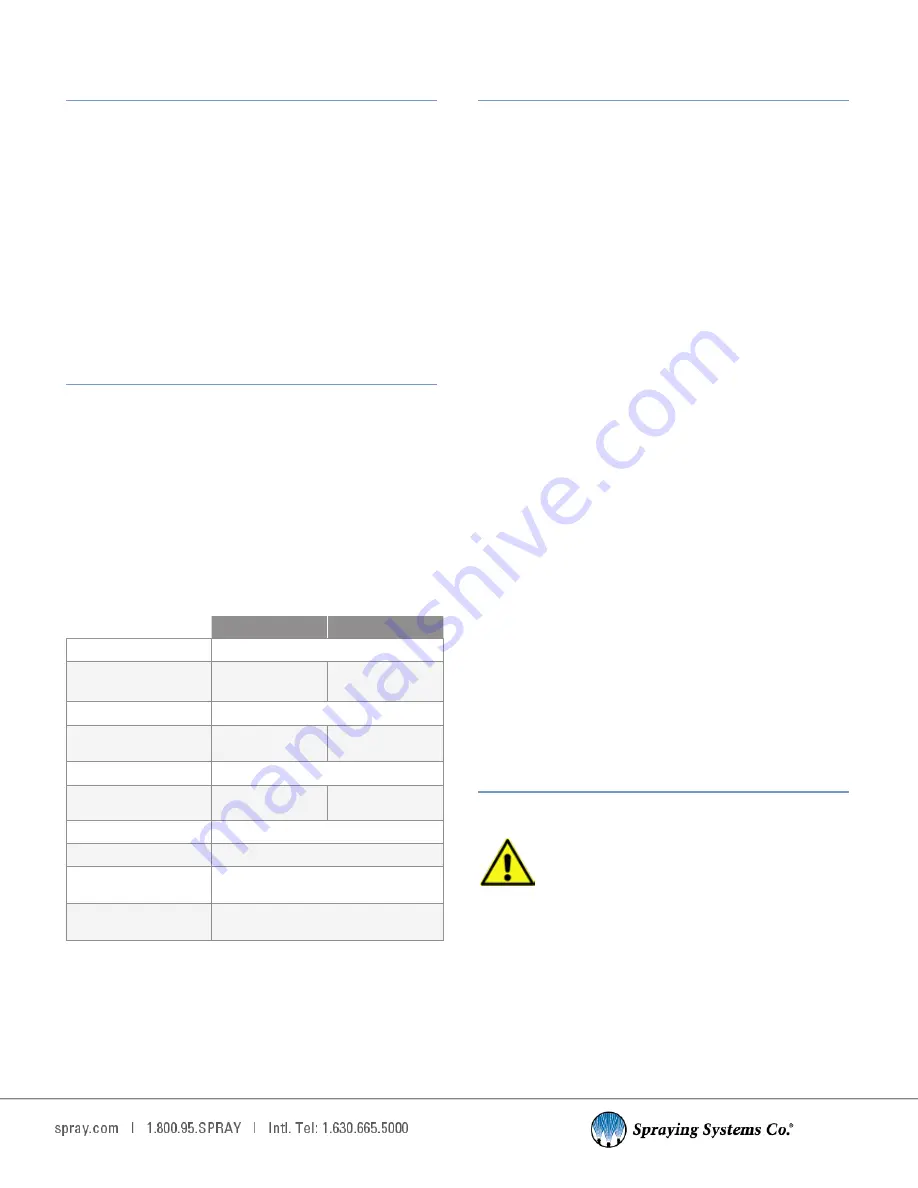

OPERATION & SPECIFICATION

TankJet 80

TankJet 80H

Pipe Connection:

1-1/2" Female NPT or BSPT

Operating Pressure

Range:

60 - 200 psi

(4.1 - 13.8 bar)

60 - 200 psi

(4.1 - 13.8 bar)

Max. Operating Temp:

250° F (121° C)

Flow Capacity:

50 - 125 gpm

(189 - 473 lpm)

60-135 gpm

(227 - 511 lpm)

Head Rotation Speed:

3 - 20 RPM

Effective Cleaning Dia.:

To 50 ft. max.

(15.3 m)

To 50 ft. max.

(15.3 m)

Nozzle Quantity

2 or 3

Approximate Weight:

15 lbs (6.8 kgs)

Material of

Construction:

316 Stainless Steel, PTFE, UHMW-PE

Recommended Strainer:

(not included)

20 Mesh (1/32 openings)

TROUBLE SHOOTING

Due to the simplicity of the unit, very few problems should

occur. If any trouble should arise, the following steps may be

taken: Refer to the Parts List.

A . Check units for external damage, look for evidence of

mishandling that may have damaged shafts, bearings, or

alignment .

B . If the nozzle body fails to rotate and no liquid passes:

1. Check for liquid pressure and volume at the unit.

2. Check strainer for filter blockage.

3. Remove unit and check for clogged jet holes.

4. With the nozzle removed, recheck for flow through

the unit.

5. Remove the inlet cap and check the holes of the

inlet disc. Check to see that no foreign material is

preventing the unit from rotating.

C . If the unit fails to rotate and sufficient liquid passes:

1. Check for freedom of rotation, by hand, in the

vertical and rotational axis.

2. If no visible abnormalities are discovered, the unit may

have been dropped and internal damage is suspect.

3. If the unit still does not rotate, check for:

a. Contamination in the unit.

b. Wear of any one of the following parts:

The bushings, washers, and the rotor.

c. Galling and straightness of the shaftsand gear.

REPLACE ALL DEFECTIVE PARTS. NO LUBRICATION!

SERVICING

REPLACEMENT PARTS:

When the machine requires replacement parts, only

Spraying Systems Co. recommended components

should be used to maintain proper machine

operation and safety.

Содержание TankJet 80

Страница 1: ...TankJet 80 80H Tank Cleaners USER GUIDE MI TJ80 TJ80H spray com...

Страница 7: ...7 TANKJET 80 PARTS LIST...

Страница 8: ...8 TANKJET 80H PARTS LIST...

Страница 11: ......