Page

/ Bulletin 30-21

OPERATION

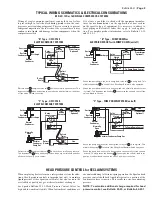

“B” TYPE

NORMAL (OUTDOOR) CONDENSER - De-energized

See Figure 1. With the pilot valve de-energized, high side pressure

is prevented from entering the cavity above the piston assembly.

At the same time, the upper pilot port is open to suction pressure.

The resulting pressure differential across the piston moves the

piston-seat assembly to close the reclaim condenser port (upper

main port). In this mode, the refrigerant flows to the normal con-

denser. The pilot valve opens the cavity above the piston to suc-

tion. This allows the reclaim condenser to be pumped out through

a small bleed hole in the piston. The pump out process reduces the

reclaim condenser to suction pressure. Once suction pressure is

reached, the flow through the bleed hole in the piston stops. There

is no high to low side bleed with continued operation in the nor-

mal condenser mode. For a more efficient pump out of the reclaim

condenser, a normally open solenoid valve can be added to the

lowest physical location of the reclaim coil to remove liquid.

“C” TYPE

NORMAL (OUTDOOR) CONDENSER - De-energized

With the pilot valve de-energized, high side pressure is prevented

from entering cavity above the piston-seat assembly. At the same

time the upper pilot port is opened to suction pressure. The result-

ing pressure differential across the piston moves the piston-seat

assembly to close the reclaim (upper) main port, thereby eliminat-

ing high to low side bleed and the resulting capacity loss with the

system in the normal condenser mode.

“B” AND “C” TYPE

RECLAIM (REHEAT) CONDENSER - Energized

When the pilot valve is energized, high side pressure is permitted

to flow through the lower pilot port at the same time the upper

pilot port is closed to suction. High side pressure build up on top

of the piston moves the piston-seat assembly to close the normal

condenser port and open the reclaim (upper) main port. With the

upper pilot port closed, there is no high to low side bleed and

resulting capacity loss with the system in the reclaim mode.

Valves using the MKC-1 coil may be used on fluids or gases where

the temperature does not exceed 240°F, while the valve ambient is

120°F. The coil is Underwriters Laboratory Class F rated.

TYPES B5D, 8D, 12D & 16D 3-WAY HEAT RECLAIM VALVES

Bulletin 30-21, April 2007 supersedes Bulletin 30-21, June 2001 and all prior publications. © 2007 by Sporlan Division, Parker Hannifin Corporation

Type

Port

Size

Connection

ODF Solder

Inches

A

B

C

D

E

F

G

H

J

B5D5B

B5D5C

5/8

5/8

5.00 4.36 3.22 3.22 0.79 3.84 0.50 2.94

1.64

8D7B

8D7C

3/4

7/8

5.18

5.06

3.44 3.44 1.13 2.63

0.75

2.89

8D9B

8D9C

1-1/8

5.13

0.91

12D11B

12D11C

1-1/4

1-3/8

6.87 6.94 4.19 4.19 2.38 4.25

0.97

12D13B

12D13C

1-5/8

1.09

12D17B

2-1/8

1.25

16D17B

16D17C

2

2-1/8

8.18 9.53 5.47 5.47 3.50 5.44 1.25 3.17

NOT FOR USE WITH HAZARDOUS OR CORROSIVE FLUIDS

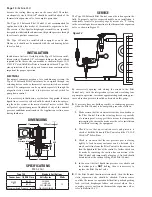

INSTALLATION

PIPING SUGGESTIONS

Valves must be installed in a horizontal or vertical position with

the coil level with or above the valve body. Install Heat Reclaim

Valves so the connections are in the proper flow direction as

shown in Figure 2.

Figure 3, page 4, shows piping schematics only to illustrate the

general installation of the Heat Reclaim Valves. Sporlan recom-

mends that recognized piping references be consulted for assis-

tance in piping procedures. Sporlan is not responsible for system

design, any damage resulting from system design, or for misap-

plication of its products.

Proper support of heat reclaim valves is essential. Concentrated

stresses resulting from thermal expansion or compressor vibra-

tions can cause fatigue failure of tubing, elbows and valve fittings.

Fatigue failures can also result from vapor propelled liquid slug-

ging, and condensation induced shock. The use of piping brackets

close to each of the three way valve fittings is recommended.

Suction

Reclaim

Condenser

Compressor

Discharge

Normal

Condenser

1/4” SAE

A

B

D

C

E

G

Optional 1/2”

Conduit Boss

J

F

Figure 2

H

Compressor

Discharge

Suction

Reclaim

Condenser

Bleed Hole

Figure 1

“B” TYPE

RECLAIM CONDENSER

PUMP OUT

DIMENSIONS – Inches