2

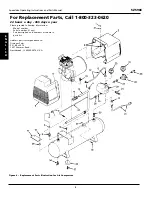

Speedaire Operating Instructions and Parts Manual

5Z598C

Speedaire

Portable Air Compressor

EXTENSION CORD

To avoid voltage drop and power loss

to the motor use extra air hose instead

of an extension cord. If an extension

cord must be used, be sure it is:

1.

A 3-wire extension cord that has a

3-blade grounding plug, and a 3-

slot receptacle that will accept the

plug on the product.

2.

In good condition.

3.

No longer than 50 feet.

4.

12 gauge (AWG) or larger. Wire

size increases as guage number

decreases. 10 AWG and 8 AWG

may also be used.

(DO NOT USE A

14 OR 16 AWG

.)

Compressor can be

operated on a 15

amp circuit if:

1. Voltage supply to circuit is

normal.

2. Circuit is not used to supply any

other electrical needs (lights,

appliances, etc.)

3. Extension cords comply with

specifications in owners

manual.

4. Circuit is equipped with 15 amp

circuit breaker or 15 amp time

delay fuse. Use a Type "T" time

delay fuse.

If any of the above conditions cannot

be met, or if operation of the compres-

sor repeatedly causes interruption of

the power, it may be necessary to

operate it from a 20 amp circuit. It is

not necessary to change the cord set.

GROUNDING INSTRUCTIONS

Improper

grounding can

result in electrical shock. In the

event of a short circuit, grounding

reduces risk of shock by providing

an escape wire for the electric

current. Air compressor must be

properly grounded.

10. Read labels and safety data for all

materials you spray. Follow all

safety precautions.

11. Use a mask or respirator if there is

a chance of inhaling toxic sprayed

materials. Masks and respirators

have limits and will only provide

protection against some kinds and

limited amounts of toxic material.

Read mask and respirator

instructions carefully. Consult a

safety expert or industrial hygienist

if you are not sure about the use of

a certain mask or respirator.

12. If the material you intend to spray

contains trichloroethane and

methylene chloride (read the label

or the data sheet), do not use

accessories that contain aluminum

or galvanized parts. You must

either change the material you

intend to spray, or use only

stainless steel spray equipment.

Trichloroethane

and methylene

chloride can also react with

galvanized components causing

corrosion and weakening of

equipment parts.

Installation

LOCATION OF AIR COMPRESSOR

Locate air compressor in a clean, dry,

well ventilated area. Air filter must be

kept clear of obstructions, which could

reduce air delivery of the air compres-

sor. The air compressor should be

located at least 12” away from the

wall or other obstructions that will

interfere with air flow. Air compressor

head and shroud are designed to allow

proper cooling. If humidity is high, air

filter can be installed to remove

excessive moisture. Follow air filter

instructions for proper installation.

General Safety Information

(Continued)

4.

Never use a motor with a higher

horsepower rating than the one

supplied.

5.

Never drill into, weld or modify air

tank.

Changing air tank

will cause it to

weaken. Tank may rupture or

explode.

6.

Do not repair a leaking tank, it

must be replaced. Never replace air

tank with a different model or

larger tank.

7.

Never point any nozzle or sprayer

toward a person or any part of the

body.

8.

Always wear safety goggles or

glasses when using air compressor.

9.

Check maximum pressure rating

for air tools and accessories.

Regulator outlet pressure must

never exceed maximum pressure

rating.

Damage may occur

to air tools and

accessories if too much air pressure

is applied.

Always unplug air

compressor prior

to maintenance or repair. Never use

air compressor outdoors when it is

raining.

Never directly

inhale the

compressed air produced by this

unit. Compressed air contains toxic

or irritating vapors which are

harmful if inhaled.

®

E

N

G

L

I

S

H