1. Mount Protium-1000 securely in 1 of the 2 recommended orientations.

2. Connect your Hydrogen gas supply to the

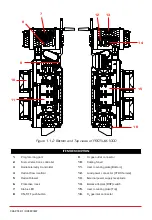

H2 gas inlet connector

. Make sure that your Hydrogen gas

supply is OFF at this stage.

3. Connect the purge tubing to the

H2 gas outlet connector

.

Caution:

Channel the purge tubing to

the back of the cooling fans and far away from the oxidant blower inlet.

4. Connect an external power supply to the

external power supply receptacle

. Make sure that it is

turned OFF at this stage. Set the

BOP switch

to 0 if you want the external power supply to continue

powering PROTIUM-1000 BOP throughout the entire operation.

5. Connect your load to the

Load power connector.

Tip

: check that the polarity is correct. It is

also advisable to put an ON/OFF switch at your load and ensure that it is turned OFF at this

time.

6. Turn on your PC and connect the communication USB cable to a USB port. Download the Spectronik Data

Acquisition (DAQ) GUI PC application from the Protium-1000 product webpage. Install the app and follow

the instructions in its user guide.

Tip:

You can also use any serial data application like Hyperterminal. Set the parameters (57600

baud rate, 8 data bit, No parity, 1 stop bit).

Reminder:

Ensure that all gas tubing and electrical wire connections are firm and secure.

PROTIUM-1000 is now ready to turn on.

CHAPTER 3 | OPERATING PROCEDURES

3

OPERATING PROCEDURES

3.1 SETTING UP PROTIUM-1000

3.2 TURNING ON PROTIUM-1000

1. Turn on the external power supply. Wait for 5s. A welcome header should appear in the GUI. LED will blink

at 10%.

2. In the GUI, click the “start” command or type the word “start” and <enter> using the keyboard function.

Alternatively, press and hold on

ON/OFF push button

for more than 2s. PROTIUM-1000 will enter its

“Starting Phase” and the message “Low H2 supply” should appear.

3. Turn on your Hydrogen gas supply.

Caution:

Ensure that the gas delivery pressure is 0.5-

0.7barg.

Insufficient delivery pressure may cause cell flooding and drop in performance, while excessive pressure

may rupture the fuel cell membrane, causing dangerous gas leakage and irreversible cell damage. Ensure

that your pressure regulator can provide Hydrogen gas flow rate of more than 15L/min.

4. PROTIUM-1000 will do a series of gas purging and internal diagnostic checks. If everything is normal, the

fuel cell will enter its “Running Phase” – indicated by the message in the GUI and a solid white LED.

PROTIUM-1000 is now ready to power your application.