M

EDIUM

D

UTY

C

OUNTERLINE

O

PERATION

O

PERATOR

’

S

M

ANUAL

1178822

REV

3

P

AGE

13

OP

E

R

ATIO

N

CHARBROILER MODELS

Each 12"-wide charbroiler section has a knob on the front panel that directly controls the flow of gas, and so

the heat. Turn the knob clockwise to increase the heat; turn it counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

To light the pilot of a charbroiler section, do the following:

1. Turn all control knobs to the “OFF” position.

2. Light the pilot tube located next to each burner. The pilot flame can be adjusted by turning the screw on

the end of the pilot fitting.

3. Turn burner knobs to “HI” position. The burners should have a 1/2" to 5/8" steady blue flame. Adjust if

necessary.

4. To turn burners off, turn knob to “OFF” position.

OPEN-TOP BURNER MODELS

Each 12"-wide open-top burner section has two knobs on the front panel that directly control the flow of gas

to the section’s two burners, and so control the heat. Turn a knob clockwise to increase the heat; turn it

counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

To light the pilots of an open-top burner section, do the following:

1. Turn all gas valves to the “OFF” position.

2. Check to make sure pilots are in the correct position.

3. Light the pilots.

4. Adjust the pilot flame as necessary.

5. Turn burner knobs to “HI” position. Each burner flame should be steady blue and impinge on the

underside of a pot placed on the support grate. Adjust if necessary.

6. To turn burners off, turn knob to “OFF” position.

OVERNIGHT SHUTDOWN

Turn knobs to the “OFF” position to turn the burners off.

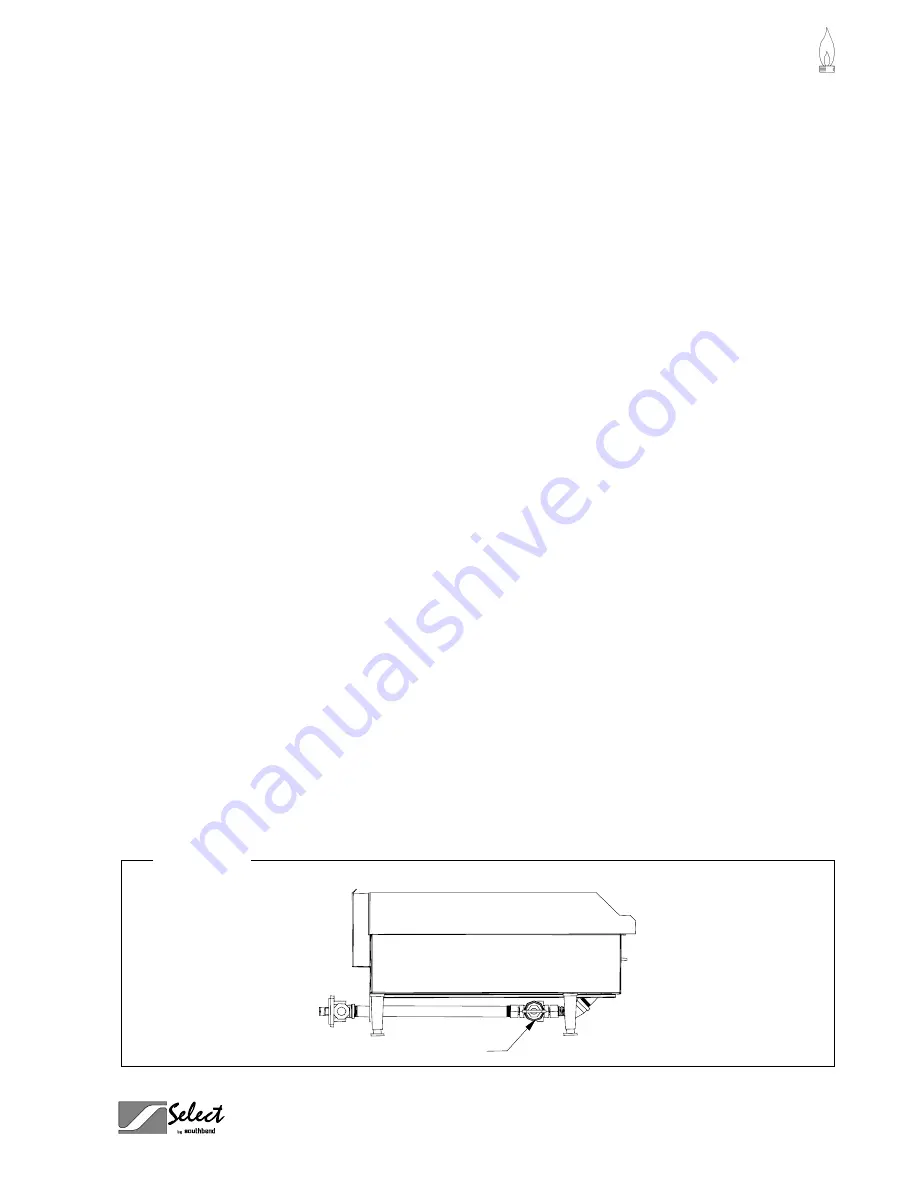

EXTENDED-PERIOD SHUTDOWN OF THERMOSTATIC GRIDDLE

To shut down a thermostatic griddle for an extended period (or before disconnecting the gas supply), turn all

manual gas valves and pilots “OFF,” then turn the main gas supply valve to “OFF” (see Figure 5 below).

Figure 5

Main Gas Supply Valve