Отзывы:

Нет отзывов

Похожие инструкции для 1364

JGR8850

Бренд: Jenn-Air Страницы: 28

DER244BSS

Бренд: Danby Страницы: 50

cr9204

Бренд: Caple Страницы: 52

800 Series RN8910GE

Бренд: Waldorf Страницы: 31

RGA520EW

Бренд: Hotpoint Страницы: 2

RH36C1W

Бренд: Toastmaster Страницы: 30

KEDS100

Бренд: KitchenAid Страницы: 26

KEDC205B

Бренд: KitchenAid Страницы: 43

KEDH207WHO

Бренд: KitchenAid Страницы: 52

KEDS100V

Бренд: KitchenAid Страницы: 21

NX58H5600S series

Бренд: Samsung Страницы: 120

NX58H5600S series

Бренд: Samsung Страницы: 252

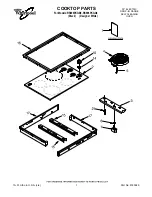

SF114PXSB1

Бренд: Whirlpool Страницы: 9

SF114PXSB0

Бренд: Whirlpool Страницы: 9

RY160LXTS0

Бренд: Whirlpool Страницы: 7

RY160LXT

Бренд: Whirlpool Страницы: 7

RS696PXGQ

Бренд: Whirlpool Страницы: 8

RS696PXGB9

Бренд: Whirlpool Страницы: 9