33

MSH/MPH series

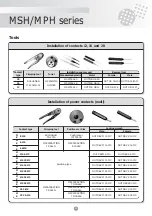

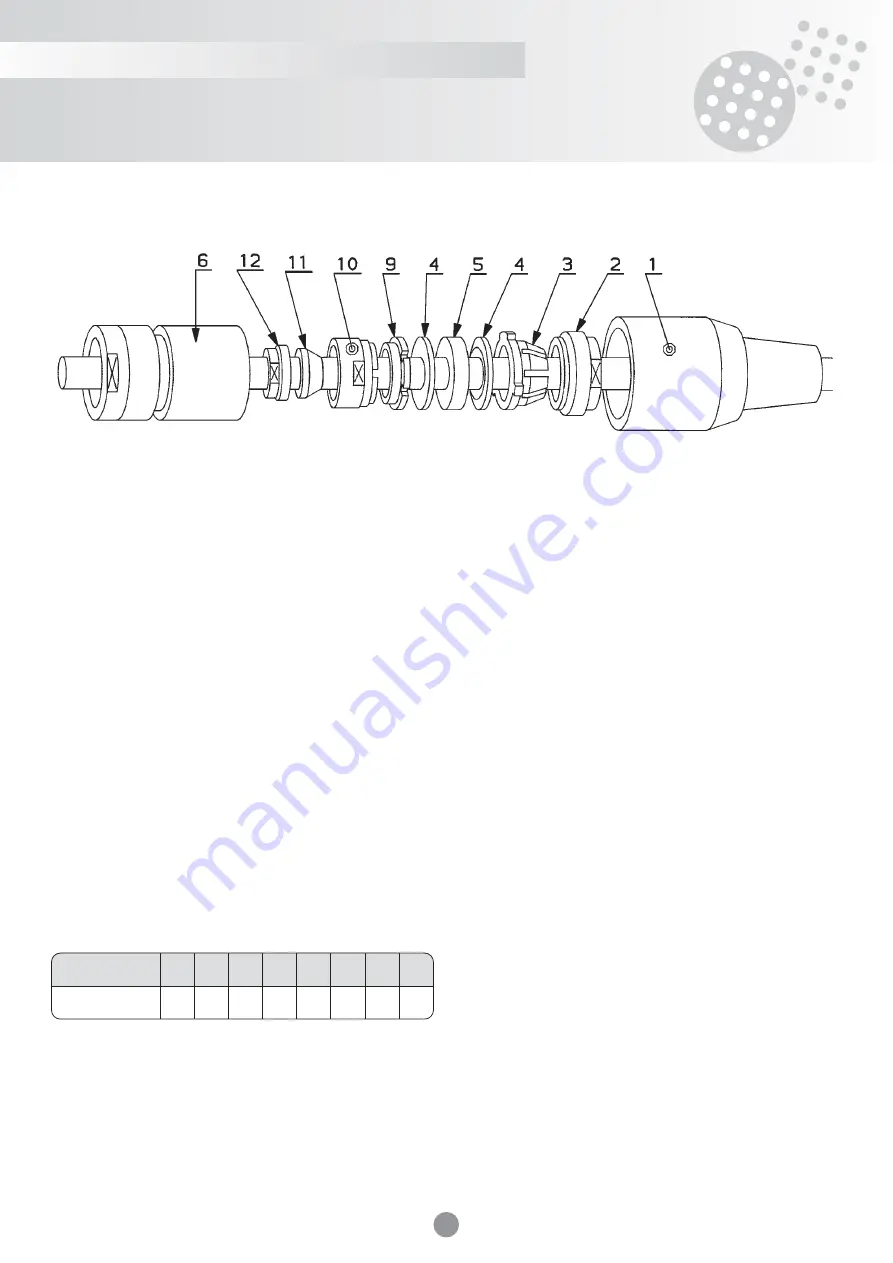

Assembly

Thread the following onto the wire, in the order shown in fig.2:

• the cable boot (1)

• the locking screw (2)

• the crimping tool (3)

• the support washer (4)

• the sealing washer (5)

• the front support washer (4)

• the slotted nut (9)

• the grip bush (10)

Strip the cable in accordance with the table above and fig.4.

Move the braid aside, and slide the cone (11) under the braid.

Bring the grip bush (10) up to the cone (11) and firmly tighten the screw

(12) into the grip bush (10).

Crimp the contacts to the end of the conductor wires. Before each crim-

ping (or each soldering in the case of soldering contacts), check that the

conductor wire is clearly visible in the sight hole (Fig. 1).

Insert the cable into the connector, having taken care to bundle the

contacts using adhesive tape or another suitable system.

• Insert the contacts in accordance with the procedure described above.

• Move the connector forward, and tighten the nut, checking that the

toothing is functioning correctly (position elbow connectors according

to direction; nuttorque following table here after).

It is advisable to fit the plug to a dummy receptacle for all screw and nut

tightening operations.

Connecting nut torque

Fig. 5

Shell size

16

17

18

20

22

24

26

28

Torque (mN)

10

13

16

20

22

25

28

30

Содержание MPH Series

Страница 1: ...Connectors for Navy Applications and Heavy Duty Industries MSH MPH SERIES...

Страница 2: ......