19

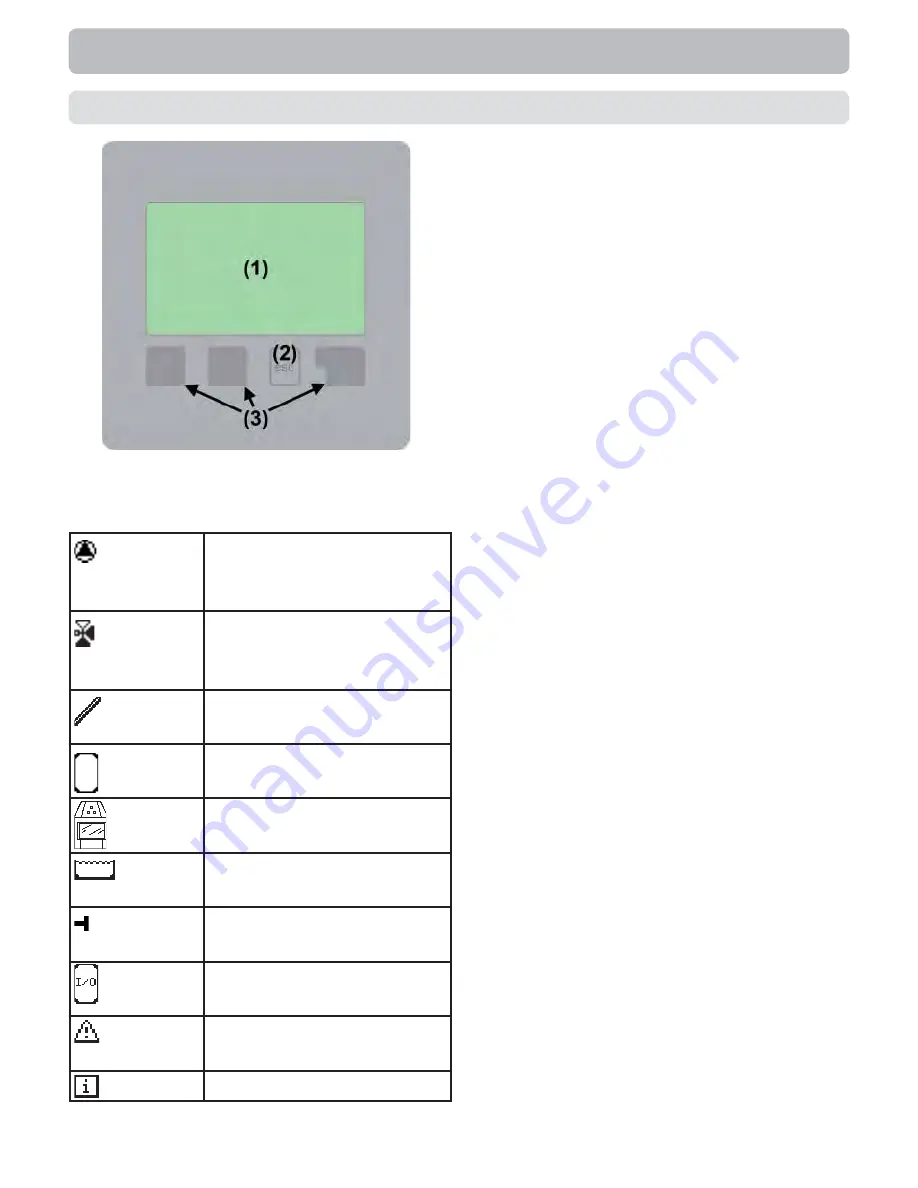

The display (1), with its extensive text and

graphics mode, is almost self-explanatory,

allowing easy operation of the controller.

Entries are made using four keys (2+3),

which are assigned to different functions

depending on the situation. The “esc” key

(3) is used to cancel an entry or to exit a

menu.

If applicable there will be a request for

confi rmation as to whether the changes

which have been made should be saved.

The function of each of the other three

keys (3) is shown in the display line di-

rectly above the keys; the right-hand key

generally has a confi rmation and selection

function.

Examples of key functions:

+/-

= increase/reduce values

▼

/

▲

= scroll menu down/up

yes/no = approve/reject

Info

= additional information

Back = to previous screen

ok

= confi rm selection

Confi rm = confi rm setting

Operation

E.1

Display and Input

Display symbols:

Pump

(rotates in operation)

Valve

(direction of fl ow black)

Collector

Storage tank

Solid fuel boiler

Swimming pool

Temperature sensor

Thermostat On / Off

Warning / error message

New information available