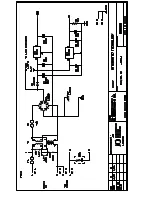

COIN MECHANISM

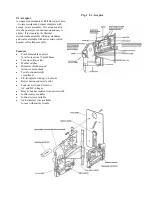

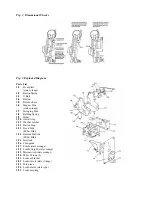

Refer to figs. 1,2, and 3

This section is intended to help the user get the most from the S1 acceptor mechanism. It discusses the adjustments

and maintenance of the acceptor and related components. No applications section can be complete, however, and

customers are always very welcome to contact us direct.

The frontplate (1/1) is the first check. This prevents entry of oversize, bent or badly distorted coins. The coin

passes onto the run-down track formed by the magnet side (1/6) and the swinging side (1/7) which are held together

by the bulldog clip (1/8). This track is inclined 14º from the horizontal to permit the coins to run down due to

gravity, and 5º from the vertical, so as to check for diameter. As the coin enters the track it passes the washer

catcher (1/11). This has a tooth which engages in the hole in a washer preventing further travel of the washer. At

this point, the coin passes an over diameter stop on the adjustable slider (1/9), which stops the passage of slightly

oversize coins.

If the coin is not over diameter, it passes further to an under diameter check. Here the coin is tilted an extra 4º from

vertical against the under diameter ridge on the slider. Under diameter coins fall past this ridge to be rejected.

The base of the track has an under thickness gate, where thinner coins fall through to reject. The coin deflecting

cones stop over thickness coins in the track by forcing the coins against the under diameter ridge in the slider.

These coins are returned by pressing the reject button (1/4) which splits the track. When the reject button is

released, it is returned to its original position by the button spring (1/2), allowing the acceptor to close up again.

Rejected coins then either exit through a chute at the bottom of the acceptor (indirect reject) or are guided via the

return chute (1/5) through the reject slot in the frontplate, and come to rest in the u-bolt (1/3).

The magnet positioned in the 'magnet-side' (1/6) of the rundown stops all ferromagnetic blanks. These can be

stripped clear by the swinging side (1/7), by pressing the reject button (1/4). The anti-tilt leg (1/10) prevents

cheating the acceptor by tilting the machine to gain acceptance of under diameter coins. If the machine is tilted, the

leg swings across the track and prevents entry of all coins.

The final test is in the black marinyl cradle (1/13 to 1/20). This incorporates a diameter check in the form of a

cradle (1/17) and weight (1/18). Under diameter coins fall straight through the cradle and fail to actuate the

microswitch (1/19). The true coin then passes through an interlock mechanism (1/15) prior to actuating the

microswitch. This interlock prevents 'coin-on-cotton' cheating and fishing. The coin guide (1/16) is adjusted to

ensure that the coin hits the microswitch arm in the correct position.

If the optional lock out assembly (1/21 to 1/25) is fitted, the lockout arm (1/24) will prevent entry of coins into the

mechanism. To enable coin acceptance, the correct voltage must be applied to the lock out coil (1/22) which will

then withdraw the lock out arm from the coin path.

ADJUSTMENT

The S1 mechanism can be adjusted both for diameter and thickness. The thickness adjustment is done first as this

effects the diameter setting. It is often impossible to do this adjustment whilst the mechanism is still within the

machine. It is therefore advisable that a spare fixed side be carried by a service engineer, so that the swinging side

can be removed from the machine (by removing the bull-dog clip), and temporarily attached to the spare. This will

allow the swinging side to be adjusted outside the machine.