5-28

SEL24105G

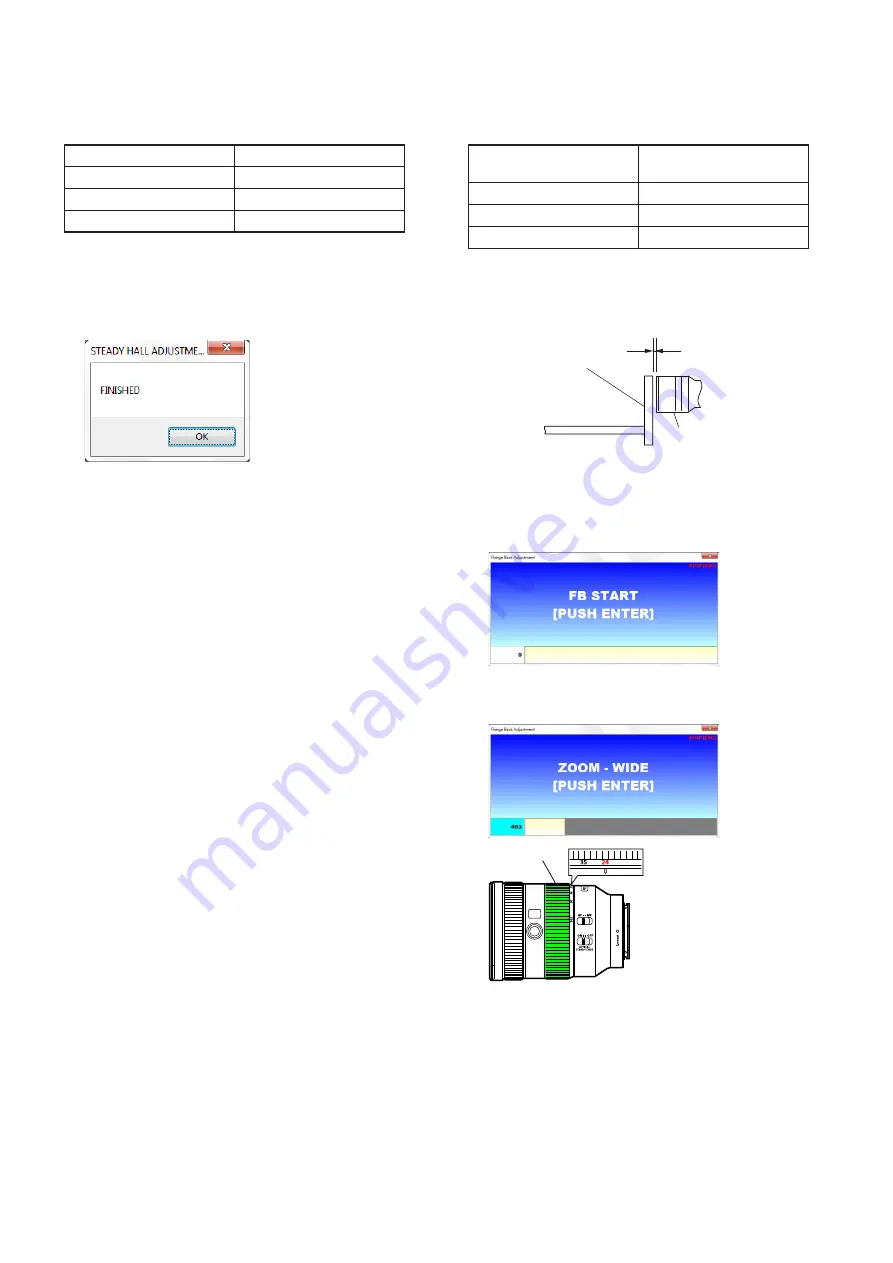

(5) Flange Back (S)

• Adjust the flange back of inner focus lens.

Subject

Flange back adjustment jig

+ FB adjustment chart

Operation on Lens side

• Zooming ring

Type of the camera

ILCE-5000

Shooting Mode of the camera P mode (Program Auto)

Preparation

Attach the FB adjustment chart to the flange back adjustment jig, and

set the flange back adjustment jig as shown in the following figure.

Flange back

adjustment jig

Within 10 mm

Lens to be tested

Zoom: TELE end

Adjusting Method

1. Click the [Flange Back (S)] button in the Adjustment and Inspec-

tion.

2. The START screen is displayed, after the preparation of adjust-

ment is completed, press the ENTER key.

3. “ZOOM - WIDE” is displayed, set the zooming ring to the WIDE

end (focal length: 24 mm).

Zooming ring

4. When the ENTER key is pressed, automatic adjustment of WIDE

end is started.

– Continued on next page –

(4) Steady Hall (S)

• Adjust the position detection hall element for shake compensation.

Subject

Not required

Operation on Lens side

Not required

Type of the camera

ILCE-5000

Shooting Mode of the camera P mode (Program Auto)

Adjusting Method

1. Click the [Steady Hall (S)] button in the Adjustment and Inspec-

tion, the adjustment will start.

2. “FINISHED” is displayed when the adjustment is completed,

then click the [OK] button.

Содержание FE 24-105mm F4 G OSS

Страница 15: ...2 12 SEL24105G 2 2 14 ZMR ASSY 2 ZMR assy 1 two screws M1 7 u 3 5 rear mount side front lens side ...

Страница 23: ...2 20 SEL24105G 2 3 5 ZMR ASSY 1 ZMR assy 2 two bosses 3 two screws M1 7 u 3 5 rear mount side front lens side ...

Страница 74: ...Revision History SEL24105G Ver Date History Contents 1 0 2017 10 Official Release ...