– 3 –

SECTION 1

GENERAL

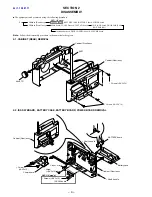

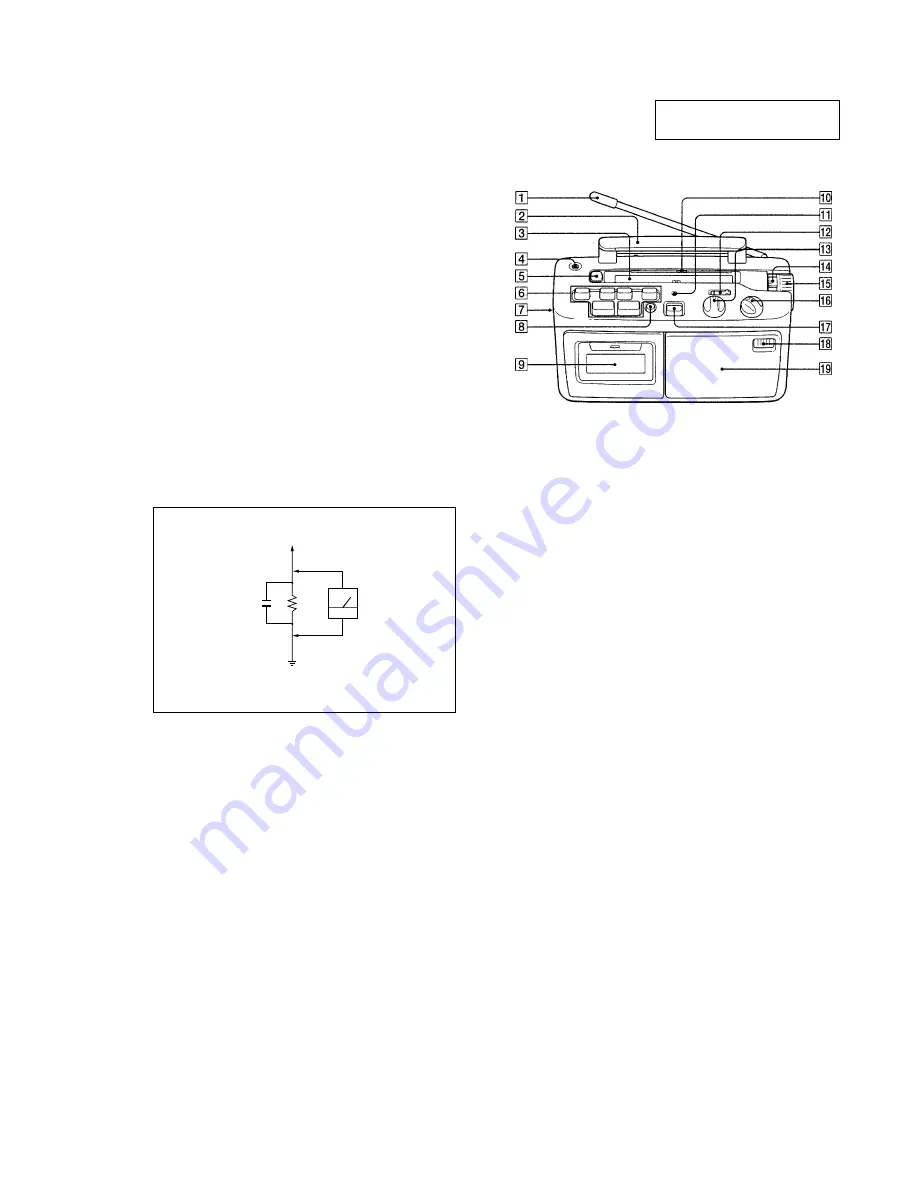

LOCATION AND FUNCTION OF CONTROLS

This section is extracted from

instruction manual.

1

FM telescopic aerial

2

Carrying handle

3

Dial scale

4

@

(earphone) jack (mini jack)

5

LIGHT (Dial scale light) button

6

Tape operation buttons

7

EARPHONE POCKET box

8

SLOW PLAYBACK button

9

Cassette compartment lid

!º

Frequency marker

!¡

OPR/BATT indicator

!™

EASY LISTENING ADJUSTMENT switch

!£

EASY LISTENING ADJUSTMENT control

!¢

BAND switch

!

∞

TUNING control

!§

VOLUME control

!¶

FUNCTION switch

!•

Built-in microphone

!ª

Speaker

SAFETY CHECK-OUT

After correcting the original service problem, perform the follow-

ing safety check before releasing the set to the customer :

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is

0.75V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a pas-

sive VOM that is suitable. Nearly all battery operated digital

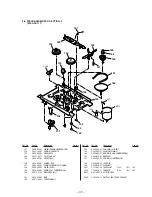

multimeters that have a 2V AC range are suitable. (See Fig. A)

AC

voltmeter

(0.75V)

To Exposed Metal

Parts on Set

Earth Ground

0.15 F

µ

1.5k

Ω

Fig. A. Using an AC voltmeter to check AC leakage.