Manual 2100-707D

Page

21 of 39

However, three phase compressors will rotate in either

direction depending upon phasing of the power.

Since there is a 50-50 chance of connecting power

in such a way as to cause rotation in the reverse

direction, verification of proper rotation must be made.

Verification of proper rotation direction is made by

observing that suction pressure drops and discharge

pressure rises when the compressor is energized.

Reverse rotation also results in an elevated sound level

over that with correct rotation, as well as substantially

reduced current draw compared to tabulated values.

Verification of

proper rotation

must be made at the time

the equipment is put into service. If improper rotation

is corrected at this time, there will be no negative

impact on the durability of the compressor. However,

reverse operation for over 1 hour may have a negative

impact on the bearing due to oil pump out.

NOTE:

If compressor is allowed to run in reverse

rotation for an extended period of time, the

compressor’s internal protector will trip.

All three phase compressors are wired identically

internally. As a result, once the correct phasing is

determined for a specific system or installation,

connecting properly phased power leads to the same

Fusite terminal should maintain proper rotation

direction.

The direction of rotation of the compressor may be

changed by reversing any two line connections to the

unit.

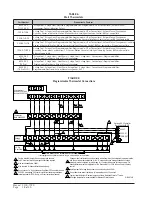

Phase Monitor

All units with three phase scroll compressors are

equipped with a three phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal (call for cooling) is present at the

phase monitor and phases are correct, the green LED

will light.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit.

Do not reverse any of the unit factory

wires as damage may occur.

Condenser Fan Operation

NOTE:

Certain models may be equipped with a low

ambient control (LAC), and if so, the condenser fan

motor will have a delayed start until system refrigerant

operating pressure builds up. After starting, the fan

motor may or may not cycle depending upon ambient

conditions. This is normal operation.

Service Hints

1. Caution owner/operator to maintain clean air filters

at all times and also not to needlessly close off

supply and return air registers. This reduces airflow

through the system, which shortens equipment

service life as well as increasing operating costs.

2. Check all power fuses or circuit breakers to be sure

they are the correct rating.

3. Periodic cleaning of the outdoor coil to permit full

and unrestricted airflow circulation is essential

.

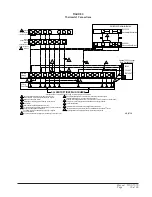

Sequence of Operation

Circuit R-Y1 makes at thermostat pulling in compressor

contactor, starting the compressor and outdoor motor.

(See

NOTE

under

CONDENSER FAN OPERATION

concerning models equipped with low ambient control.)

The G (indoor motor) circuit is automatically completed

by the thermostat on any call for cooling operation or

can be energized by manual fan switch on subbase for

constant air circulation. On a call for heating, circuit

R-W1 makes at the thermostat pulling in heat contactor

for the strip heat and blower operation. On a call for

second stage heat, R-W2 makes bringing on second

heat contactor, if so equipped.

Balanced Climate

TM

Mode

Balanced Climate™ is a great comfort feature that can

easily be applied under any normal circumstances. If

the air conditioning system is being set up in a typical

environment where 72°F is the lowest cooling setpoint,

remove the Y1/Y2 jumper and install a 2-stage cooling

thermostat. This will increase the humidity removal

up to 35% and provide a much more comfortable

environment.

If the application is likely to require air conditioning

operation below 60°F outdoor conditions, a low

ambient control (LAC) kit must be installed.

The LAC

kit is equipped with an outdoor temperature switch

that disables Balanced Climate mode when the outdoor

temperature drops below 50°F. This prevents potential

evaporator coil freeze up issues. The LAC kit also

comes with an evaporator freeze protection thermostat

that cuts out the compressor if the evaporator begins to

freeze up.

If the unit is being installed with any ventilation

package, an LAC kit must be installed.

Failure to utilize

an LAC with any air conditioner can cause coil freeze

up.

Balanced Climate can readily be applied to duct-free

(supply and return air grille) applications. It may also

be applied to ducted applications with

limited static

of 0.20" ESP (total including both supply and return

statics)

. Consult Bard Application Engineering for

details prior to implementation.

CAUTION:

Balanced Climate is not a replacement for

a dehumidification (hot gas reheat) unit for extreme

applications, but rather an enhancement feature for

limited climates and applications.