Lit. No. 70451, Rev. 06

20

November 1, 2018

OPERATING THE SPREADER

VIBRATOR FUNCTION

A heavy-duty vibrator is standard equipment on the

model VX-1500 spreader. Turn the vibrator ON as

needed to keep dense material

fl

owing and prevent

bridging of material in the hopper.

A second vibrator can be added. Accessory vibrator

kits are available through your authorized dealer.

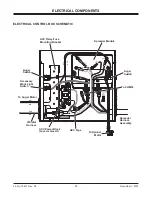

CONTROLLING THE FLOW OF MATERIAL

Inverted V and Discharge Baf

fl

e

The V-Maxx™ 1500 hopper spreader uses an

inverted V baf

fl

e design over the auger area. This

baf

fl

e is used to reduce the load to the auger drive

train. It must not be removed unless servicing the unit.

This spreader also uses a discharge baf

fl

e to reduce

material leakage. Do not remove the discharge baf

fl

e

unless servicing the unit.

Baf

fl

e Extension

The baf

fl

e extension is intended to be used with very

dry products that free-

fl

ow with little effort. The baf

fl

e

is designed to keep these types of materials from

leaking out.

• If using damp/wet materials, remove this baf

fl

e by

removing the self-drilling screws.

• If using a sand/salt mixture, remove the baf

fl

e

extension.

AUTO-REVERSE (Ar) FEATURE

The spreader is automatically able to sense and clear

material jams. The sensitivity level of the auto-reverse

feature is adjustable.

Adjusting the Auto-Reverse (Ar) Setting

1. With the spreader connected and the control

powered up in the READY mode, press and hold

the BLAST button. After 5 seconds, a number will

appear on the status display (factory default is 20).

2. Continue to hold the BLAST button and turn

the right-hand knob to control the material

fl

ow

setting (range is 2–30). Turn the knob clockwise to

increase the

fl

ow. Turn the knob counterclockwise

to decrease the

fl

ow.

3. Release the BLAST button.

4. Press the ON/OFF button twice (turning the

spreader ON, then OFF) to save the setting.

5. If auto-reverse is too sensitive or not sensitive

enough, repeat Steps 1–4 and adjust the value. If

the value is set to 30, the auto-reverse feature will

be disabled

.

Auto-Reverse (Ar) Sequence

The

Ar

sequence will begin automatically, and consist

of a series of reverse-then-forward movements of the

auger.

The

Ar

sequence will make up to

fi

ve attempts to

clear the jam. The status display will

fl

ash

Ar

then a

number, and repeat as it counts down from 5 to 1. If

the jam is cleared, the auger will automatically return

to normal operation at the previous control settings.

If auto-reverse is unsuccessful, then the operator must

extract the material that is causing the problem. Follow

all warning directions when clearing jams.

CAUTION

Disconnect electric power and tag out, if

required, before servicing or performing

maintenance.

Baffle

Extension

Self-Drilling

Screws

Discharge

Baffle

Inverted V