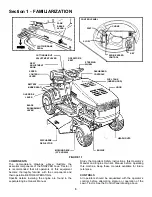

12

Section 3 - MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the Tractor, use genuine SNAPPER

replacement parts only. Contact a local SNAPPER dealer

for parts and service assistance. For the correct part or

information for a particular Tractor, always mention the model

and serial number. SNAPPER recommends returning the

Tractor to an authorized SNAPPER dealer annually for

inspection and addition of any new devices, which might

upgrade the safety of the Tractor. For the nearest

SNAPPER dealer in your area, check the yellow pages

under the heading LAWN MOWERS. For engine parts and

service, look for the engine manufacturer’s dealers under the

heading, ENGINES - gasoline.

3.2 SERVICE - AFTER FIRST 5 HOURS

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blades running. STOP blades.

STOP engine. Set park brake. Remove key. Remove

spark plug wire from spark plug and secure wire away

from spark plug. Engine and components can be

extremely hot. Avoid burns by allowing engine and

components sufficient time to cool.

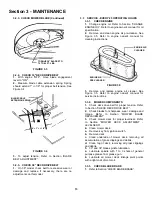

3.2.1. CHANGE ENGINE OIL

The engine is equipped with a Fastex

™

oil drain.

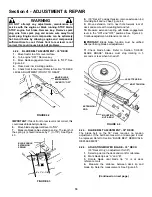

1. Rotate drain body counterclockwise and pull out to

open drain. See Figure 3.1.

2. Drain oil into a 2 quart container placed beneath

end of oil drain.

3. After all oil has drained, push drain body "IN" and

rotate clockwise to close.

4. Fill engine with new motor oil as specified in engine

owner's manual.

WARNING

The following procedure requires the engine and

blades to be operated. Exercise extreme caution. Clear

area of loose parts & tools first. Only operate blades

when seated in the operator’s seat.

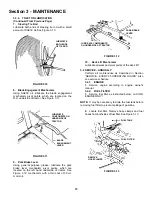

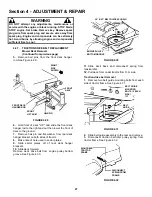

3.2.2. CHECK BLADE BRAKE

1. Check blade brake for proper function. Blades

should stop rotating in 5 seconds or less after moving

the blade engagement lever down to the OFF position.

2. If blades continue to rotate longer than 5 seconds

do not operate machine. Refer to Section “BLADE

BRAKE ADJUSTMENT” or contact your SNAPPER

dealer for assistance.

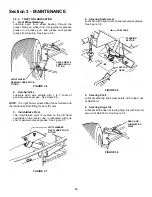

3.2.3. CHECK MOWER BLADE

1. Remove deck from tractor.

2. Carefully position deck to access blade.

3. Check blade for sharpness, wear and damage.

Refer to Section “BLADE WEAR LIMITS”.

4.

Check blade for straightness. Refer to Section

“ADJUSTING MOWER BLADE”.

5.

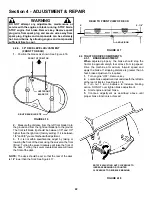

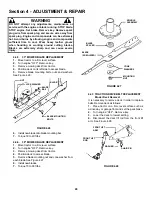

Check torque of blade mounting bolts. Torque to:

33” deck – 30 to 40 ft. lbs. See Figure 3.2.

38” deck – 70 to 80 ft. lbs. See Figure 3.3.

FIGURE 3.1

FIGURE 3.2

WARNING

Blades must stop rotating in 5 seconds or less after

blades have been turned off. DO NOT operate machine

until blade brake has been adjusted and functioning

properly. Contact your SNAPPER dealer for assistance.

OIL

FILLER

TUBE

ROTATE COUNTER-

CLOCKWISE AND PULL

OUT TO OPEN.

PUSH IN AND ROTATE

CLOCKWISE TO CLOSE.

FASTEX™

OIL DRAIN

TORQUE 33” BLADE TO

30 TO 40 FT. LBS.

NOTE: BRIGGS &

STRATTON ENGINE

PICTURED

Содержание LT145H33GBV

Страница 38: ...38 PRIMARY MAINTENANCE...

Страница 39: ...39 PRIMARY MAINTENANCE...

Страница 40: ...40 PRIMARY MAINTENANCE...

Страница 41: ...41 PRIMARY MAINTENANCE...