13

Operating the Tractor

General Operating Safety

Be sure to read all information in the Safety and

Operation sections before attempting to operate this unit.

Become familiar with all of the controls and how to stop

the unit.

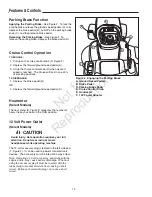

Adding Fuel

To add fuel:

1. Remove the fuel cap (A, Figure 3).

2. Fill the tank. Do not overfill. Leave room in the tank for

fuel expansion. Refer to your engine manual for

specific fuel recommendations.

3. Install and hand tighten the fuel cap.

Starting The Engine

1. While sitting in the operator’s seat, fully depress the

brake pedal or set the parking brake.

2. Make sure that your feet are not depressing the

ground speed control pedals and that the cruise

control lever is in neutral.

3. Disengage the PTO clutch.

4. Set the throttle to FULL.

5. Close the choke.

NOTE: A warm engine may not require choking.

6. Insert the ignition key and turn it to START.

7. After the engine starts, move the engine throttle

control to half speed. Warm up the engine by running

it for at least 30 seconds.

8. Set throttle to FULL.

NOTE: In the event of an emergency the engine can be

stopped by simply turning the ignition switch to STOP.

Use this method only in emergency situations. For

normal engine shut down follow the procedure given in

STOPPING THE TRACTOR.

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is still hot from recent operation. Do not

allow open flame, smoking or matches in the

area. Avoid over-filling and wipe up any spills.

Do not use gasoline containing METHANOL,

gasohol containing more than

10% ETHANOL, gasoline additives, or white

gas because engine/fuel system damage

could result.

SAFETY INTERLOCK

SYSTEM TESTS

This unit is equipped with safety interlock switches and

other safety devices. These safety systems are present

for your safety: do not attempt to bypass safety

switches, and never tamper with safety devices. Check

their operation regularly.

Operational SAFETY Checks

Your unit is equipped with a seat switch safety system.

Check the seat switch operation every fall and spring

with the following tests.

Test 1 — Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

• The cruise control lever is NOT in NEUTRAL.

Test 2 — Engine SHOULD crank and start if:

• Operator is sitting in seat, AND.

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

• The cruise control lever is in NEUTRAL

Test 3 — Engine should SHUT OFF if:

• Operator rises off seat.

Test 4 — Blade Brake Check

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned OFF (or operator rises off seat). If mower

drive belt does not stop within five seconds, see your

dealer.

Test 5 — Reverse Mow Option (RMO) Check

• Engine should shut off if reverse travel is attempted if the

PTO has been switched on and RMO has not been

activated.

• RMO light should illuminate when RMO has been

activated.

WARNING

If the unit does not pass a safety test, do not

operate it. See your authorized dealer. Under

no circumstance should you attempt to defeat

the purpose of the safety interlock system.

Not

for

Reproduction

Содержание ELT18540

Страница 2: ...N o t f o r R e p r o d u c t i o n...

Страница 29: ...N o t f o r R e p r o d u c t i o n...

Страница 30: ...N o t f o r R e p r o d u c t i o n...

Страница 31: ...N o t f o r R e p r o d u c t i o n...