11

Service

OPERATION

Before operating this machine, become familiar with all controls and functions of this unit and the tow vehicle.

Also complete all maintenance requirements and read all safety warnings. By knowing both machines thor-

oughly, how it operates and by doing the prescribed maintenance steps, you can expect relatively trouble-free

operation for years to come.

TOW VEHICLE

You will need a 22HP minimum tow vehicle, with a 2600 lb. minimum load capacity.

1. Clevis Hitch - You will need a

3

/

4

diameter by 4" pin with some type of lock.

2. Ball Hitch - You will need a 2" ball and a locking pin for the coupler.

3. 5th Wheel Hitch - You will need the 5th wheel hitch mechanism mounted on your tow vehicle.

4. After the sweeper is hooked to the tow vehicle, you must raise the jack then turn it so that the foot of the

jack is under the tongue of the sweeper.

DAILY CHECKLIST

1. Check engine oil level. Add as needed. DO NOT OVERFILL.

2. Tire pressure should be 18 psi (1.3 bar) on Sweep Star V62 tires and 20 psi (1.4 bar) on castor wheels.

3. Inspect electrical system for loose connections or frayed wiring, including battery cables. Replace any

faulty equipment or tighten if loose.

4. Check hardware for loose or missing nuts, bolts, screws, etc., and tighten or replace as needed.

5. Inspect hydraulic lines for damage or leaks. Never use hands to inspect leaks.

6. Check hydraulic oil level in right side tank. The level should be 2" to 2

1

/

2

" (5-6.4 cm) from top of tank when

fluid is cold. If level is low, add SAE 10W-40 API Service SJ or higher motor oil.

7. Check controls for smooth, proper working operation. Lubricate as needed.

8. Check and clean all debris from engine compartment.

9. Check coolant tank level. Fill as needed.

STARTING ENGINE

1. Make sure the fuel flow valve, located on the fuel tank, is “ON.”

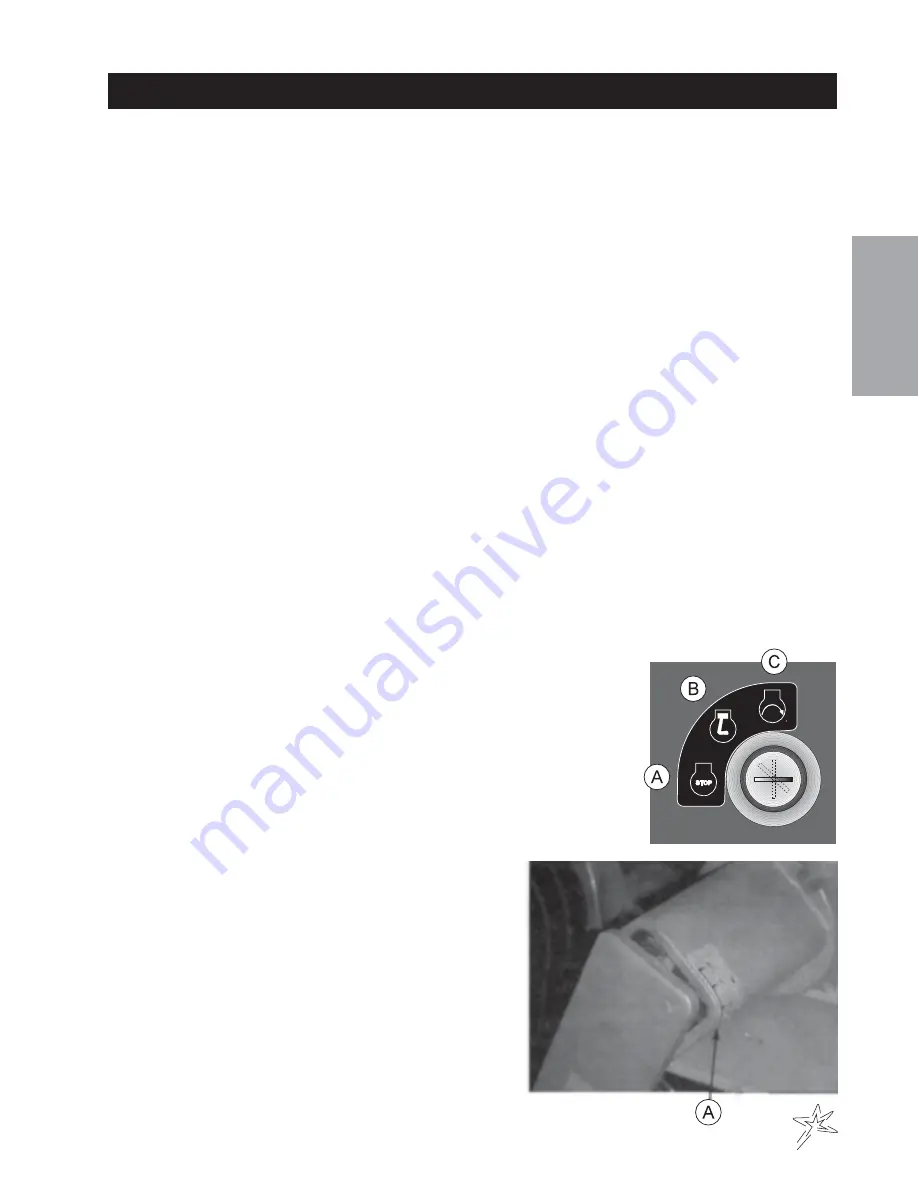

2. The ignition switch is located on remote operator control panel. Insert key

(A) and turn clockwise until engine starts (C). Release key and it will return

to run position (B). Use choke and hand throttle as necessary.

3. Allow engine to idle and warm up a few minutes.

4. Be sure the jack is all the way up and will clear all

ground obstacles.

ADJUSTMENT OF BELT TENSIONER

There are two belt tensioners on the Sweep Star V62. One

controls the tension on the belt from the engine to blower

shaft the other controls the belt on the finger or brush reel.

The proper tension of the idler should be 12 to 15 as per the

gauge (A) on the side of the tightener. Over tightening the belt

will shorten the life of the belt and the machine may not per-

form to the best of its ability. To adjust belt tensioner, loosen

bolt holding tensioner. Bring idler pulley tight to belts and turn

tensioner into belts to 15°. Tighten holder bolt.

Содержание 78-200-B

Страница 16: ...14 Diagrams WIRINGDRAWING...

Страница 18: ...16 Diagrams HYDRAULICDRAWING...