COSMOS 302X series servo drives / inverters

Installation, use and maintenance manual - EN

Ver. 1.01

25

5.3.2 Motor wiring

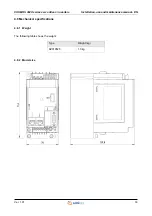

The power wiring must be made by means of a 6-pole terminal board; the following picture shows the pin con-

figuration.

Here are the specifications of the cables to be used for wiring:

The terminal board contacts must be tightened by means of a flat-blade screwdriver (blade width: 3.5 mm) or

by means of a cross-head screw-driver (PH 0); the recommended tightening torque is 0.55 Nm ±10%.

The conductor section size depends on the maximum current; in case of installation in the electrical panel of

a machine, please consider that the EN 60204-1 Standard does not allow the use of cables with a cross-section

smaller than 0.75 mm2 inside the housings and 1.0 mm2 outside (0.75 mm2 for multicore cables). To connect

the motor, a shielded multicore cable with a cross-section of 0.75 mm2 may be an excellent choice in most

applications.

The motor must be connected as shown in the following picture:

Minimum cross-section of solid conductor * **

0.75 mm

2

Maximum cross-section of solid conductor * **

2.5 mm

2

Minimum cross-section of flexible conductor * **

0.75 mm

2

Maximum cross-section of flexible conductor * **

2.5 mm

2

*= Use 60/75 °C wires only (UL)

**= Use Copper Conductors only (UL)

Motor wiring

Label

Signal

W1

Phase output W - motor 1

V1

Phase output V - motor 1

U1

Phase output U - motor 1

W2

Phase output W - motor 2

V2

Phase output V - motor 2

U2

Phase output U - motor 2