Step 6. If the Tank continues to run-on, push down lightly on the Flush Valve Actuator. If the water stops running, it is an

indication that the Flush Valve Cartridge requires tightening (clockwise). If water still runs on while pushing down on the

actuator, the Flush Valve Cartridge requires loosening (counter-clockwise).

NOTE:

Adjust the Flush Valve Cartridge Assembly in quarter to half turn increments until the water stops running. Always turn

the water supply off for all adjustments. Flush Valve Cartridge turns the water off.

Step 7. If replacement of the Flush Valve Cartridge is necessary, follow the instructions in Step 5.

CONDITION:

Weak or Sluggish Flush.

Step 1. Check the water pressure (20psi - 125 psi recommended). If OK,

then check the Flush System by removing the tank Cover and tripping

the Actuator. While the unit is flushing, gently raise the Actuator. Water

should flow freely and wash away any debris in the supply line and

Vessel.

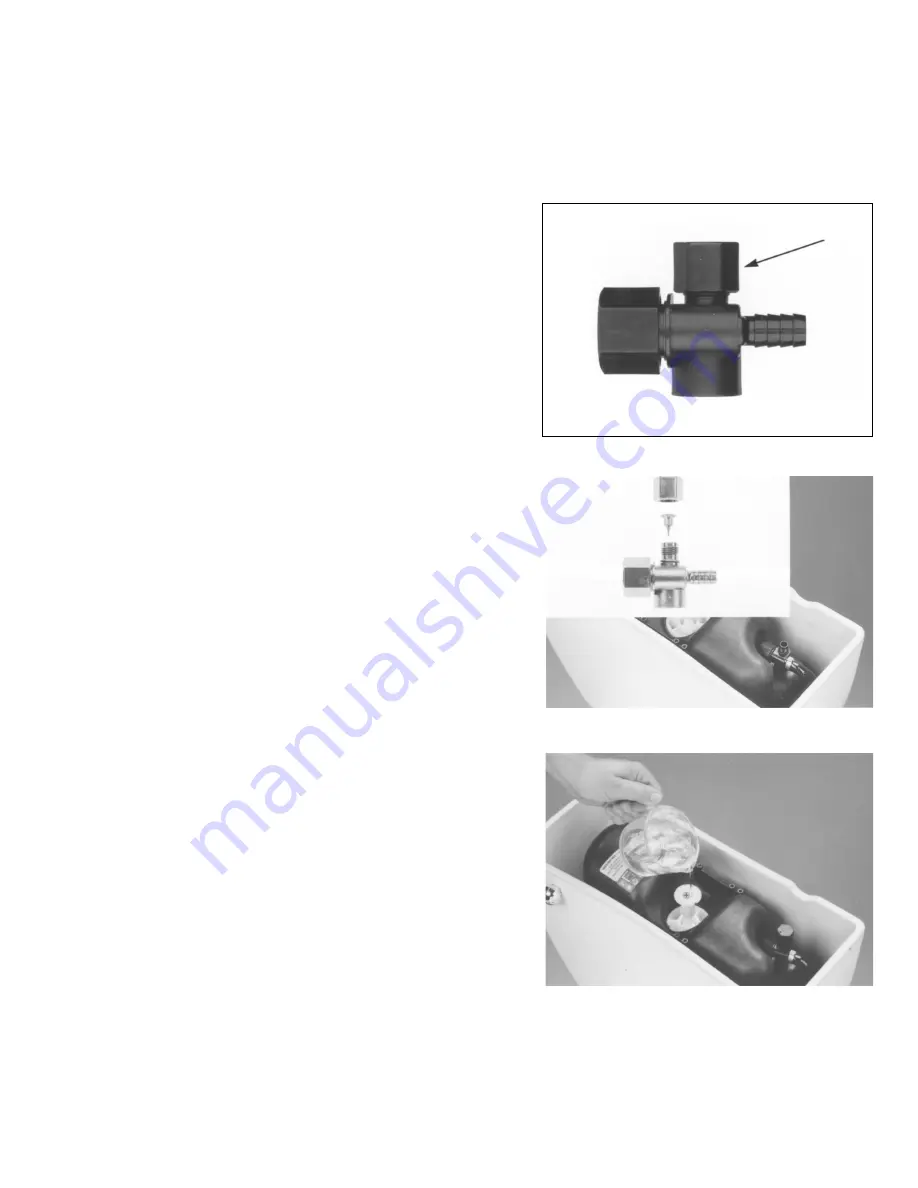

Step 2. Check the Air Inducer for sufficient air draw. The Air Inducer is

designed to draw air during the refill cycle. To test the Air Inducer, place

a small amount of water (2 to 3 drops) in the orifice of the Air Inducer

cap and flush the toilet. If the Air Inducer is functioning properly the

water will be drawn in. If not, it will need to be cleaned and tested again.

TO CLEAN AIR INDUCER:

(Figures 3 & 4)

a) Turn off the water supply and trip the Actuator.

b) Unscrew the Air Inducer Cap, clean thoroughly and remove

any obstructions. Reassemble. (Hand-tighten ONLY.)

c) Turn on water supply. Wait for the Vessel to refill (30 to 60

seconds.) Repeat

Step 2 above. If the Air Inducer does not

function properly, replace the Upper Supply Assembly.

Step 3. Check the Flush Valve Cartridge for leaks. Turn the water supply

off and drain the vessel by tripping the Actuator and holding it down

until completely drained. Next, pour a cup of water onto the Cartridge

Housing area as shown in Figure 5. Turn on the water supply. If a leak is

detected (a steady flow of bubbles from the center of the Cartridge

Area), the Cartridge should be replaced.

Step 4. Check Lower Supply. Turn the water off and relieve the Vessel

pressure by flushing the toilet. Remove the supply line connection to the

shank. Remove any obstruction in the supply shank screen. If

necessary, you can use a small brush to gently brush the screen.

Reattach the supply line to the supply shank and observe connections to

assure no leakage.

IMPORTANT:

If you are still experiencing a weak or

sluggish flush after this point, it is recommended you replace the entire

Lower Supply group.

Step 5. Check the following:

1. water line pressure (20-125psi)

2. obstruction in the bowl trapway

3. obstruction in the drain

4. proper drain ventilation

Consult a professional for recommendations if any of these conditions

exist. If the drain and drain vent are clear, and the flush has not been

improved, replace the Lower Supply Assembly.

FIGURE 3

FIGURE 4

FIGURE 5

Air Inducer Cap