4

SX80/185T & SX100/185T External sternthruster assembly

1.0.5 - 2016

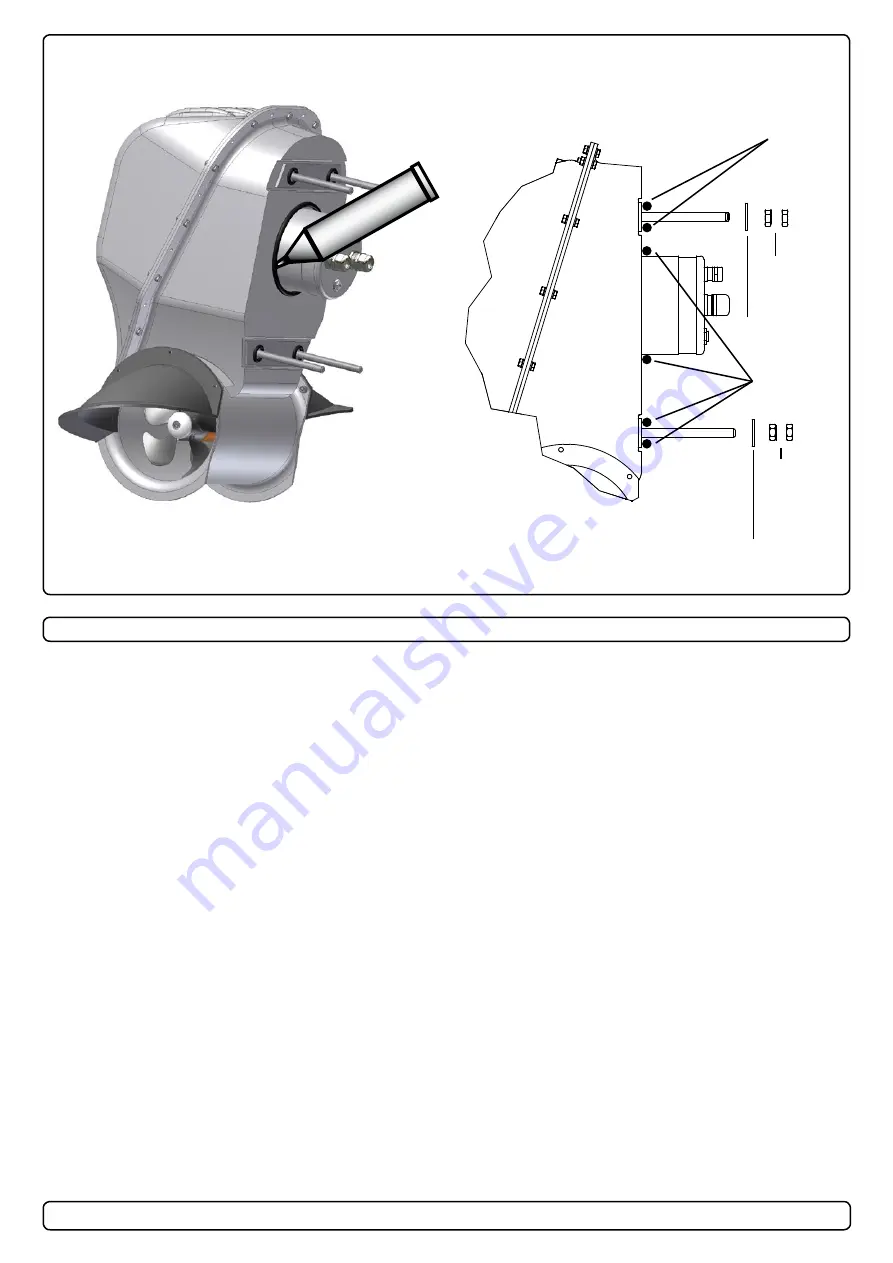

Bolt on installation of the sternthruster assembly

1. Make sure that there are enough space both inside and out-

side the transom of the boat.

NOTE:

Make sure no part of the thruster is lower than the tran-

som or protrudes outside the transom on either side - the

lowest part of the thruster must be minimum 19mm over

the bottom of the transom. Please take note of both A

and B minimum measurements on the dimension draw-

ing, page 5. A is most significant if the hull bottom angle

is more than 24 degrees, B is most significant if the hull

bottom angle is less than 24 degrees.

Refer to drawing on page 5 and attached drilling template.

2. Once the place for the installation has been decided, use the

drilling template and drill the holes.

3. It is important that the thruster assembly sits flush on the

transom. If this is not so, then the area on the transom will

have to be flattened to ensure a snug fit.

PS ! Take care with grinders as it is very easy to remove to

much in fibreglass

4. When fitting the thruster assembly, ensure that there is ample

sealant (Sikaflex or similar) around the center tube with cable

connectors and around the bolts to make a water tight fitting

(Fig. 1/2).

Bolts diameter: ø 12mm stainless steel

If a bow thruster is also installed, we strongly advice to

use separate battery banks for the two thrusters to avoid

extreme voltage drop if both thrusters are to be used at the

same time. Refer to the thruster manuals for adviced battery

capacity and cable sizes for each thruster.

Also ensure that you do not have direct connections of both +

and - if you have built together controls for both thrusters to

avoid current leakage between separate battery banks.

If you are installing the standard Sidepower dual joystick

panel this is already secured.

SEALANT

SEALANT

WASHER

NUT+

LOCKING

NUT

WASHER

SEALANT

Fig. 1

Fig. 2

NUT+

LOCKING

NUT