General cutting

Use scrap lumber to check the

settings and to get the feel of

operating the band saw before attempting regular

work.

• Do not turn the power on before all adjustments have

been made. Check to make sure the upper guide is in

place. Always keep the upper blade guide close to

your work, approximately 1/8" (3.2 mm) above the

workpiece.

• Do not force the workpiece against the blade. Light

contact permits easier cutting and prevents unwanted

friction and heating of the blade.

• Sharp saw blades need little pressure for cutting.

Steadily move the workpiece against the blade without

forcing it.

Use the band saw for straight line operations such as

cross-cutting, ripping, miter cutting, beveling, compound

cutting, and resawing.

To avoid twisting the blade, do not turn sharp corners;

instead, saw around corners.

A band saw is basically a “curve-cutting” saw. It is not

capable of doing intricate inside cutting as can be done

with a scroll saw.

Do not use this band saw to cut

ferrous metals.

When backing out the workpiece, the blade may bind in

the kerf (cut). This is usually caused by sawdust

clogging the kerf or when the blade comes out of the

guides. If this happens:

• Place the switch in the OFF position. Wait until the

saw has come to a complete stop, then remove the

switch key from the switch assembly. Store key in a

safe place.

• Unplug the saw from the power source.

• Wedge the kerf open with a flat screwdriver or

wooden wedge.

• Open front cover and turn the upper wheel by hand

while backing out the workpiece.

17.

Operation

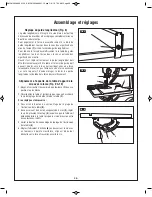

Cutting curves

When cutting curves, carefully turn the workpiece so the

blade follows without twisting. If the curve

is so sharp that you repeatedly back up and cut new

kerf, use a narrower blade, or a blade with more set

(teeth further apart). When a blade has more set, the

workpiece turns easier but the cut is rougher.

When changing a cut, do not withdraw the workpiece

from the blade. The blade may get drawn off the

wheels. To change a cut, turn the workpiece and saw

out through the scrap material area.

When cutting long curves, make relief cuts as you go

along.

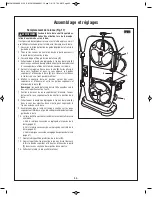

Circle cutting (Fig. 23)

1. Adjust the upper blade guard to 1/8" (3.2 mm) above

the workpiece.

2. Use both hands while feeding the work into the blade.

Hold the workpiece firmly against the table.

Use gentle pressure. Do not force the work, allow the

blade to cut.

3. The smallest diameter circle that can be cut is

determined by the width of the blade. For example, a

1/4" (6.4 mm) wide blade will cut a minimum diameter of

approximately 1 1/2" (38.1 mm).

76.2

FIG. 23

WARNING

!

WARNING

!

Minimum Circle Diameter

Minimum Radius

Blade Width

1

1/2” (12.7 mm)

1/4” (6.4 mm)

1/8” (3 mm)

2

1” (25.4 mm)

1/2” (12.7 mm)

3/16” (4.7 mm)

3

1-1/2” (38.1 mm)

3/4” (19.05 mm)

1/4” (6.4 mm)

4

3” (76.2 mm)

1-1/2” (38.1 mm)

3/8” (9.5 mm)

SM 2610028633 01-13_SM 2610028633 01-13.qxp 1/9/13 7:24 AM Page 17