Sinterit LISA PRO User Manual | 8

3. Removing and cleaning the printout

1. Once the screen displays a message saying

FINISHED

the printing process is over. Choose

REMOVE PRINTOUT

to

retrieve it from the print chamber.

2.

After the print is finished, the screen may show a message saying

MAINTENANCE TIME

. It contains information on

required maintenance to certain components of the printer in the near future. For more information consult the full

instruction manual, section

13. Maintenance

. Press

GOT IT

. If the message hasn’t appeared, it means that at present

no components require any maintenance.

3. Press the

UNLOCK LID

button to release the electrolock and allow the print chamber to be opened

IMPORTANT!

After 10 seconds the lock will re-engage and it will no longer be possible to lift the lid. If you still

want to open the printer lid, press the

UNLOCK LID

button again on the screen.

4.

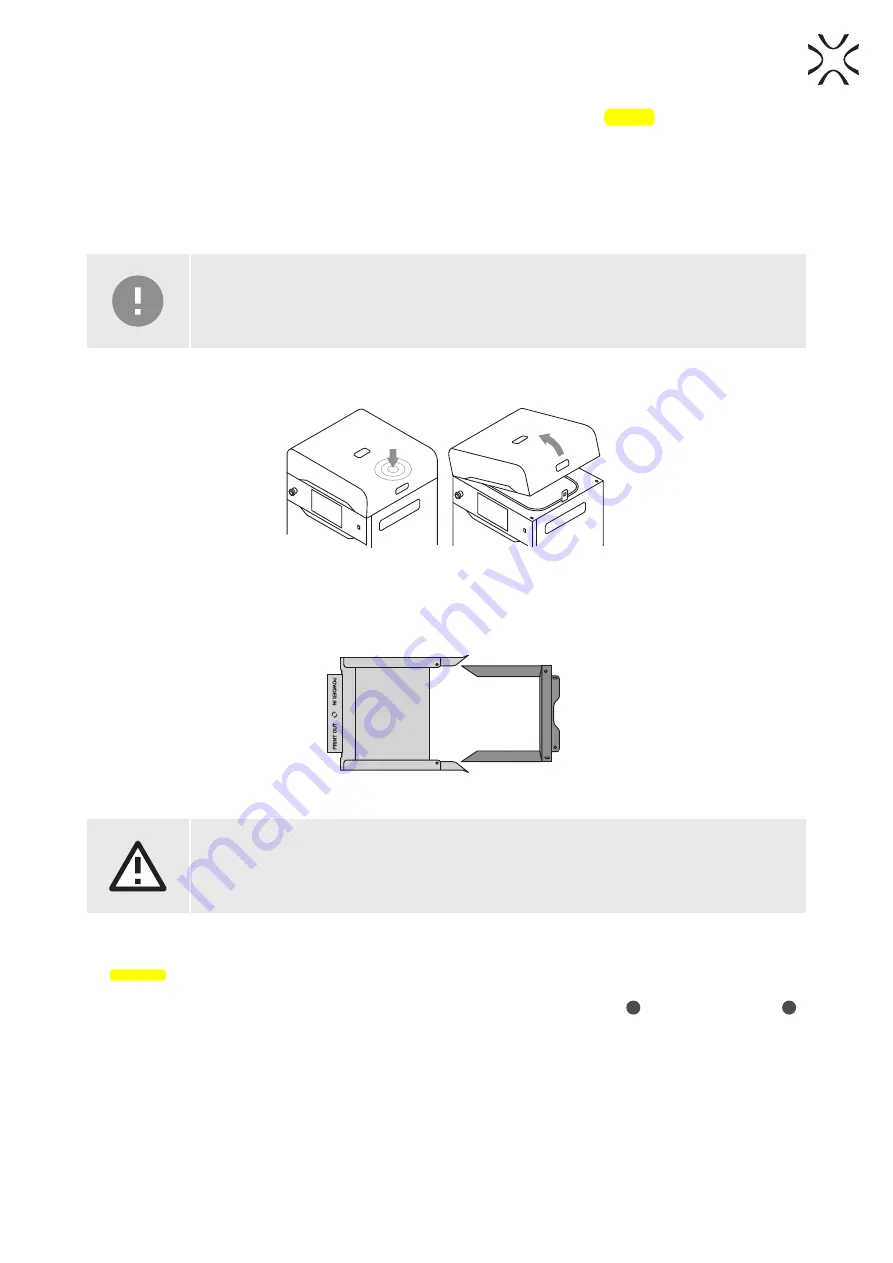

Push on the lid and pull it up using the handle (fig. 3.1).

Fig. 3.1 Lifting the printer lid

5.

Place the folded IO BOX inside the print chamber. Make sure its elements are arranged like in the picture (fig. 3.2.)

FEED BED

PRINT BED

Fig. 3.2 The proper arrangement of the IO BOX, allowing the user to remove the finished printout.

ATTENTION!

While placing the IO BOX in the chamber, make sure you do not accidentally damage its components.

6. Unfold the IO BOX elements as much as possible. Inside the IO BOX you should see a covered Feed Bed and an

uncovered Print Bed.

7. Choose

REMOVE PRINTOUT

and wait until the contents of the Print Bed (the cake) are ejected.

8. Join the IO BOX elements together.

9. Carry the IO BOX and its contents onto the foldable tray from Dedicated Powder Tools

1

or on the PHS worktop

2

then press

DONE

on the screen.