12

instructions given in section 4.3. The

gas feed pressure must under no

circumstances exceed 50 mbar.

– after have ultimated the conversion

of the boiler, please stick onto the

casing panel the plate showing the

relevant feeding gas which is inclu-

ded into the conversion kit.

NOTE: After assembling all the gas

connections, a test for gas tightness

must be carried out using soapy

water or special products. DO NOT

USE NAKED FLAMES.

4.6

DISASSEMBLY OF

EXPANSION VESSEL

To disassemble the boiler expansion

vessel, proceed as follows:

– make sure that the water has been

emptied out of the boiler;

– unscrew the connection connecting

the expansion vessel to the boiler

and the two self-tapping screws that

fasten the system to the bracket.

NOTE: Before refilling the system,

make sure that the expansion vessel

is pre-loaded at 1 bar pressure.

4.7

CLEANING AND

MAINTENANCE

At the end of each heating season, it is

essential to have the boiler thoroughly

checked and cleaned out. Proceed as

follows:

– turn the switching knob to OFF to stop

electric power reaching the boiler;

– close the gas feed cock;

– disassemble the outer casing;

– remove the smoke chamber,

unscrewing the screws that fasten it

to the combustion chamber;

– disassemble the gas burner-manifold

unit, as described in Section 4.5;

– to clean the burners, blow in a jet of

air, so as to remove any dust parti-

cles that may have accumulated;

– clean the heat exchanger, removing

any dust or residue from combustion;

– when cleaning the heat exchanger or

the burners, chemical products or

steel brushes MUST NOT BE USED;

– make sure that the tops of the bur-

ners with the holes are free from

encrustations;

– reassemble the items removed from

the boiler, making sure to follow the

correct sequence;

– check the chimney to make sure

that the flue is clean;

– check operation of the equipment

and of the main burner.

Preventive maintenance and checking

of efficient operation of equipment

and safety devices must be carried

out at the end of each season.

4.8

FAULT FINDING

Main burner does not start either to

draw off D.H.W. or heating.

– Check operation of smoke pressure

switch.

– Check, and if necessary replace,

smoke pressure switch.

– Replace electronic card.

– Check if SM is interrupted.

Fan turns but burner does not start.

– Check whether connection tubes of

smoke pressure switch PF are

obstructed and, if necessary, clean

away impurities or condensate.

– Smoke pressure switch PF needs

recalibrating or, better still, replacing

with a new factory-calibrated one.

Fan fails to turn.

– Check whether electric power is rea-

ching the terminals of the activator

motor.

– Motor winding is burnt out; replace.

– Replace electronic card.

Main burner fails to modulate both in

D.H.W. phase and in heating phase.

– Modulator M has a break in winding;

replace.

– Electronic card is faulty; replace.

Boiler makes noises and a sizzling

sound.

– Check whether circulating pumps

are obstructed; if necessary, clear

them out.

– Unclog impeller of circulating pump,

clearing away any impurities or sedi-

ments.

– Circulating pump is burnt out; replace.

– Check boiler output is adequate for

actual needs of heating system.

Boiler safety valve keeps going into

action.

– Check whether system cold charge

pressure is too high; keep to recom-

mended values.

– Check whether safety valve is out of

calibration; if necessary, replace.

– Check pre-loading pressure of

expansion vessel.

– Replace expansion vessel if faulty.

Radiators fail to heat up in winter.

– Knob is set to SUMMER. Turn it to

WINTER.

– Room stat TA is set too low or needs

replacing because faulty.

– Electrical connections of room stat

TA are wrong.

Radiators warm up also in summer.

– Check for right setting of knob.

– Check no impurities are present in

the non-return valve seat.

– Non-return valve is faulty; replace.

– Install non-return valve on system

return pipe.

Main burner burns badly: flames too

high, too yellow.

– Check that pressure of gas reaching

burner is regular.

– Check burners are clean.

Water from boiling unit isn’t suffi-

ciently hot.

– Air is still present at the top of the

boiler. Purge off through air relief

valve.

– Reduce hot-water drawing-off rate.

Smell of unburnt gases.

– Check boiler is properly clean.

– Check draught is sufficient.

– Check whether gas consumption is

too high.

Boiler operates but does not increa-

se temperature.

– Check whether gas consumption is

not lower than it should be.

– Check boiler is clean.

– Check boiler is sized in proportion to

system.

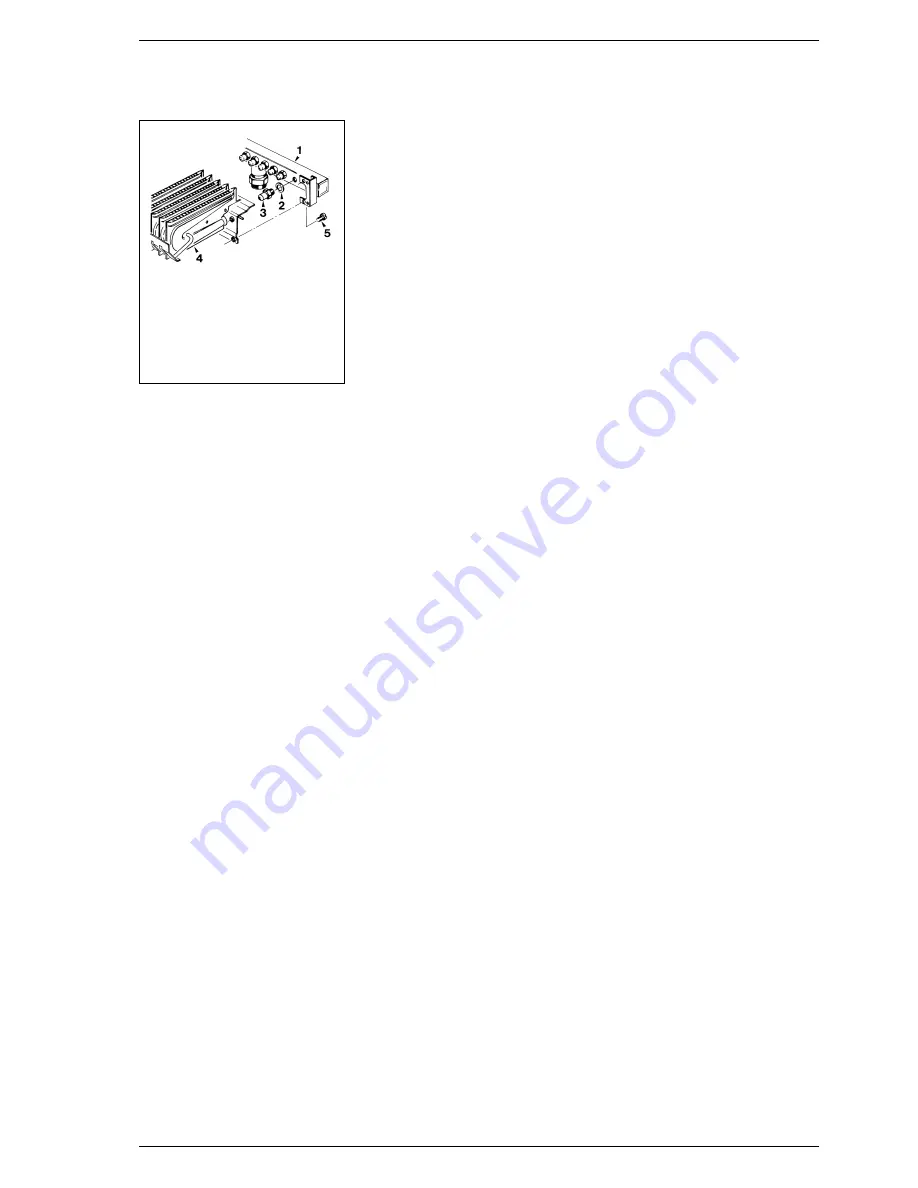

KEY

1

Burner manifold

2

Copper washer ø 6.1

3

Nozzle M6

4

Burner unit

5

Screw TCB M4 x 6

Fig. 19

Содержание Super four

Страница 1: ...Super four Installation and servicing instructions GB...

Страница 15: ......