REKORD AY

Operating manual - English

8

Copyright Silca 2019

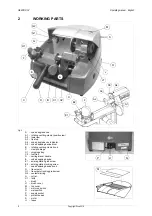

3.1

Further Risks

ATTENTION: there are residual hazards in the cutting zone (A) where the

cutter is located. Carefully observe the warnings in the manual.

•

To fit or remove keys from the clamp STOP THE

MOVEMENT OF THE CUTTER by means of the switch (N). If

this is not done the carriage may cause a hazard by going

unexpectedly towards the moving cutter.

•

After setting up the cutting code take care NOT TO MOVE

your free hand towards the cutter zone (A).

Fig. 5

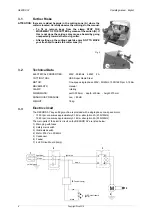

3.2

Technical Data

ELECTRICAL PROPERTIES:

230V - 50/60Hz 440W 2A

CUTTING TOOL:

HSS Super Rapid Steel

MOTOR:

One-speed single phase 230V - 50/60Hz; 1350/1620 rpm 0,18 Kw

MOVEMENTS: manual

CLAMP: rotating

DIMENSIONS:

width: 330mm - depth: 430mm - height: 270mm

SONOROUS PRESSURE:

Leq. = 83 dB

WEIGHT: 18

kg.

3.3

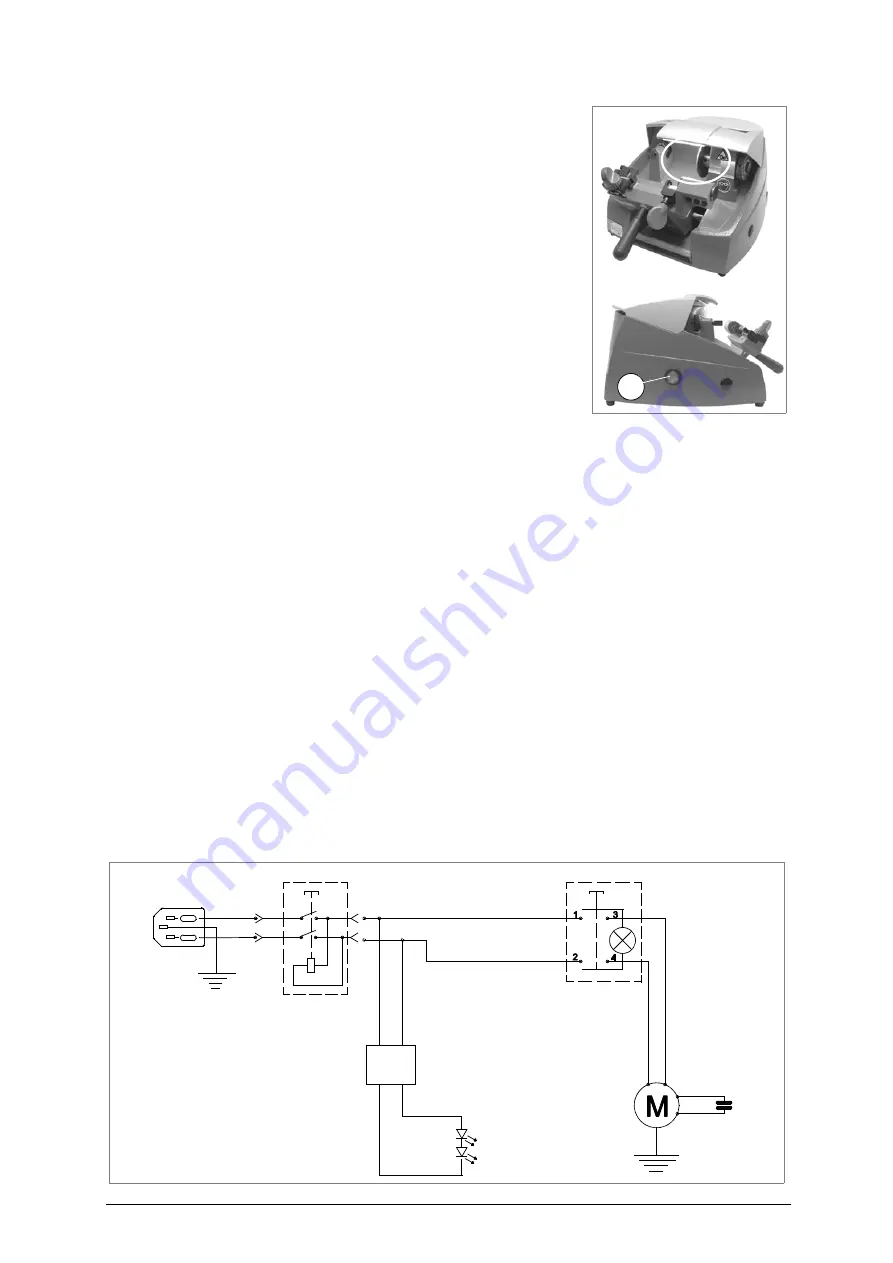

Electric circuit

The REKORD AY key-cutting machine is provided with a single phase one-speed motor;

-

1350 rpm, consumes approximately 0.18 Kw, absorption 2A (230V/50Hz)

-

1620 rpm, consumes approximately 0.18 Kw, absorption 2A (230V/60Hz)

The main parts of the electric circuit on the REKORD AY are listed below:

1) Main plug with fuses

2) Safety main switch

3) Illuminated switch

4) Motor: 230V a.c. 50/60Hz

5) Condenser

6) Feeder

7) 6 LED circuit board (lamp)

A

N

black

red

Feeder (lamp)

6 LED circuit board

brown

light blue

light blue

brown

yellow/green

1

2

3

6

4

7

5

(

)

(

)

(lamp)

Содержание Rekord AY

Страница 1: ...D434249XA vers 4 0 Operating manual Translation of the original instructions...

Страница 4: ......