‡ SIGNET

2540 High Performance Flow Sensor

Page 4 of 8

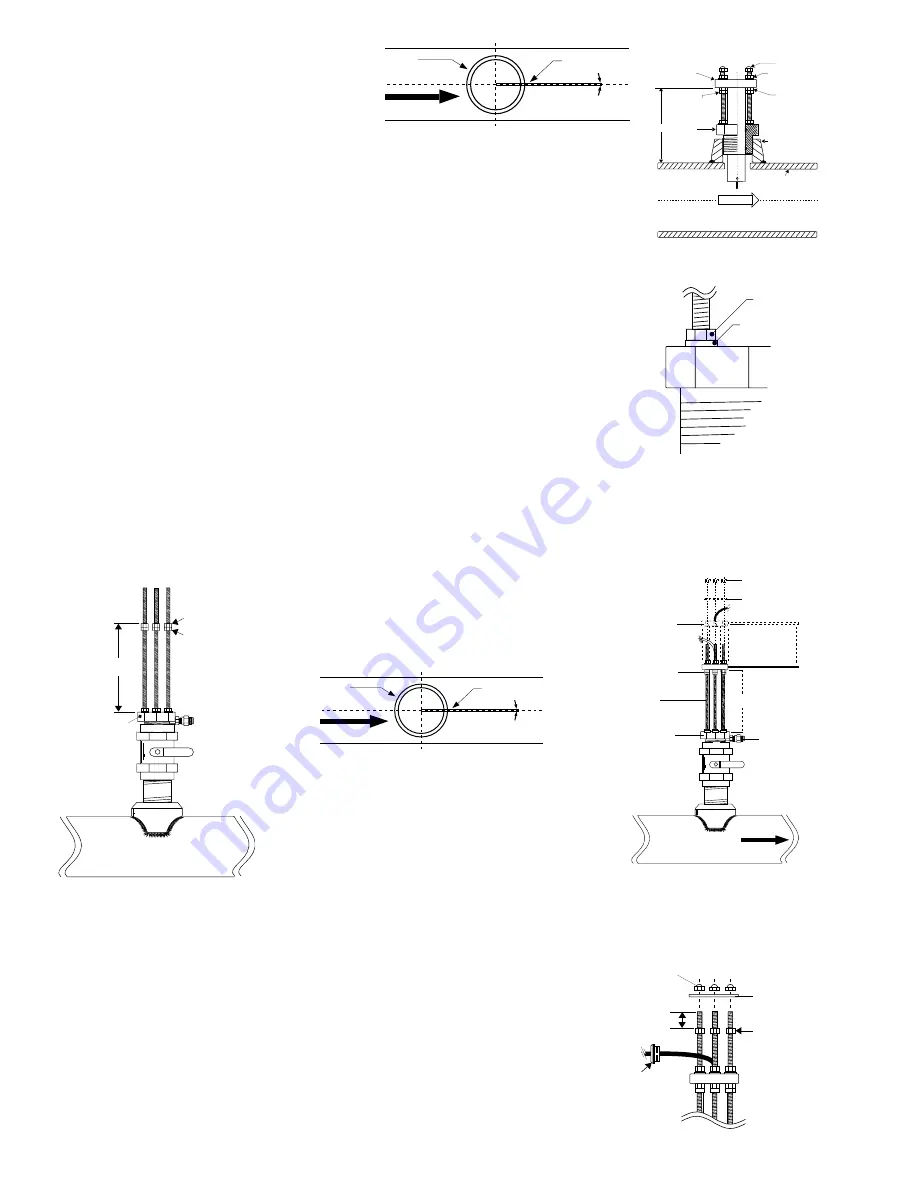

lower hex nut

and jam nuts

sensor flange

18 inch

threaded rods

359 mm (14.14 in)

process pipe (side view)

direction of flow

alignment rod

Upper hex nuts

(3/16 x 1/4-20)

1/4 in. lock

washers

sensor

fitting

bleed valve

cable

grommit

25mm

(1.0 in.)

protector plate

hex nut (3/16 x

1/4-20)

protector plate

removed during

sensor installation

protector plate

cap nuts

lower hex nuts

(3/16 x 1/4-20)

jam nuts

(5/32 x 1/4-20)

359 mm

(14.14 in.)

sensor

fitting

UNDER PRESSURE!

alignment

rod

sensor

flange

process pipe

(top view)

The flow alignment rod

MUST

be

parallel to the process pipe as shown.

flow direction

F.

Thread protector plate hex nuts onto each of the three threaded rods. Adjust each hex nut to a

height of approximately 25 mm (1 in.) from the top of each rod. Remove the black plastic cable

grommet in top of sensor with a screwdriver. Slide the grommet up the cable away from sensor.

(Fig. 12)

Fig. 9

Fig. 10

Fig. 11

D.

Place the alignment rod in the alignment hole on the

sensor flange. Align the flange so rod is parallel to the

process pipe. (Fig. 6)

E

.

Thread upper hex nuts with lock washers until they

contact the sensor flange and tighten. Check for proper "H"

dimension and readjust if necessary. (Fig. 7)

4.7 Hot-Tap Sensor Installation

A.

Thread one hex nut onto each of the three threaded

rods included in package. Install threaded rod with a lock

washer onto the sensor fitting. Secure rods in place by tightening each hex nut against the sensor fitting.

(Fig. 8)

B.

Thread one jam nut and lower hex nut onto each threaded rod so that the top surface of each

nut is 359 mm (14.14 in.) from the top surface of the sensor fitting. Secure each hex nut with a

jam nut. (Fig. 9)

CAUTION: This setting is critical to ensure an adequate sensor seal and to prevent the rotor

from hitting the isolation valve orifice during installation.

C.

Wipe the sensor body with a dry, clean cloth. Orient the alignment hole on the sensor flange

to point

downstream

. Place the slotted flange over the threaded rods. Lower the sensor into the

fitting until the sensor flange rests on the lower hex and jam nuts.

D.

Secure the sensor with lock washers and upper hex nuts on the top of the flange. Before

tightening, align the sensor flange so that the alignment rod is parallel and level with the process

pipe. (Fig. 10 & Fig. 11)

E.

Make sure the bleed valve is closed (full clockwise position).

"

H

"

process

pipe wall I.D.

sensor

fitting

upper hex nuts

& lockwashers

lower hex nuts

jam nuts

sensor

flange

cap nuts

female pipe fitting

FLOW

sensor fitting

hex nut

Lock washer

alignment

rod

sensor

flange

process pipe

(top view)

The flow sensor alignment rod

MUST

be

parallel to the process pipe as shown.

flow direction

Fig. 6

Fig. 7

Fig. 8

Fig. 12