84/238

Building Technologies

Modular Heating Controller RMH760B

CE1P3133en

HVAC Products

6 Boiler temperature control

05.02.2007

313

3S

73

MnPu

TBo

TRtBo

BoPu

VlvRtMx

VlvShOff

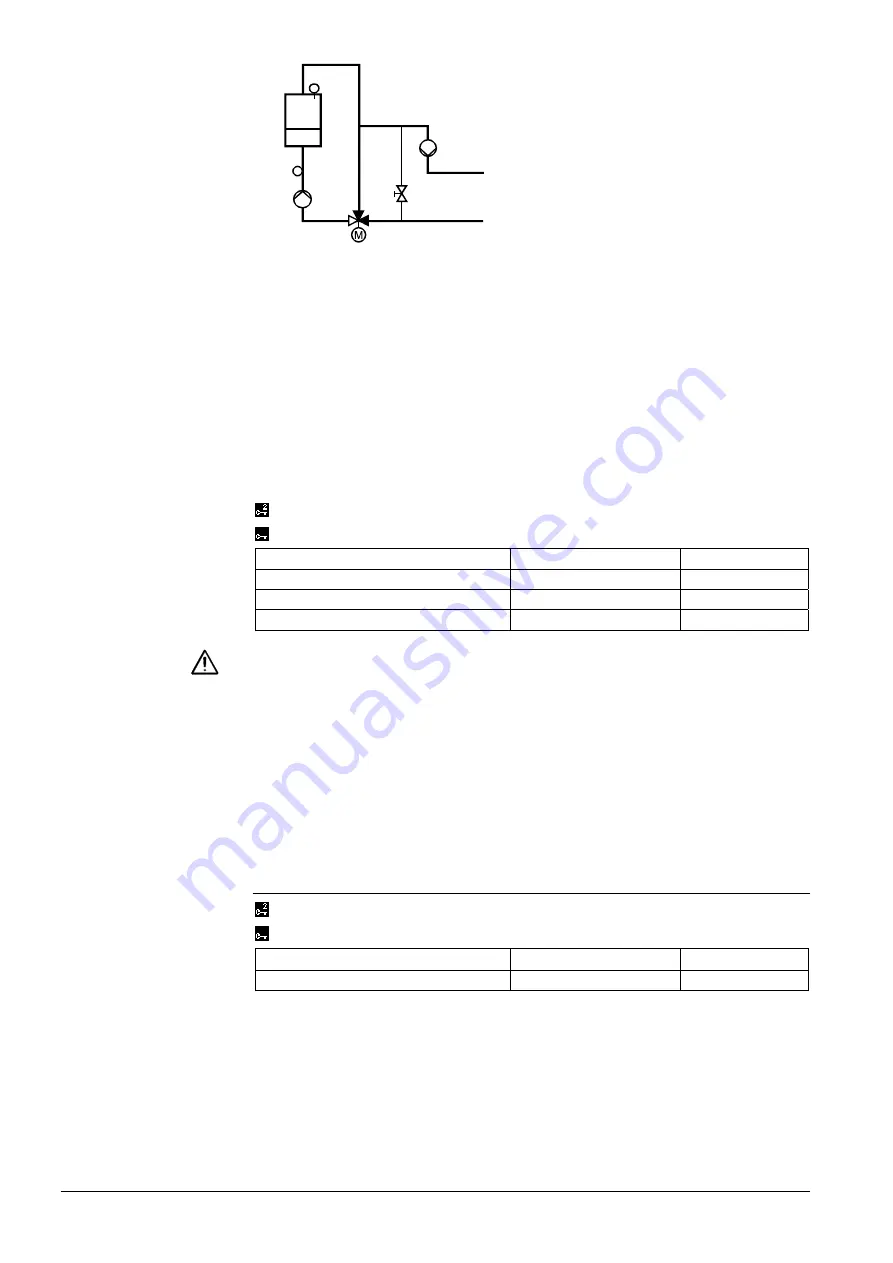

The 3-port mixing valve ensures both protective boiler startup and maintained boiler

return temperature.

The main pump can also be configured, in addition to the boiler pump. In that case, it

must be made certain that the main pump will not operate when the mixing valve is fully

closed. To prevent this, a bypass or overflow valve can be installed.

In this type of plant, the main pump provides the function of a system pump. And with

this type of plant, it must be made certain that the main pump will not operate when the

main controller’s mixing valve is fully closed. It is recommended not to use a mixing

valve in connection with the main controller.

To adapt the control parameters to the type of plant (actuator and controlled system),

the same setting parameters as those used with the mixing heating circuit are available.

For more detailed information, refer to section 5.7 “Mixing valve control”.

Main menu > Commissioning > Settings > …

or

Main menu > Settings > Boiler > Return control

Operating line

Range

Factory setting

Actuator run time

1…600 s

120 s

P-band Xp

1…100 K

50 K

Integral action time Tn

0…600 s

60 s

If a minimum return temperature shall be ensured, the minimum boiler temperature

must be selected accordingly. The minimum boiler temperature must be higher than the

minimum return temperature.

In the case of plants with mixing valve for the maintained boiler return temperature, the

mixing valve will be driven to the fully closed position when the return temperature

sensor is faulty and then deenergized to allow manual adjustment.

If no return temperature sensor is configured, a fault status message will appear.

If a return temperature sensor is configured but no return temperature limitation set, the

sensor will only be used for display purposes.

6.6.12 Protection against pressure shocks

Main menu > Commissioning > Settings > …

or

Main menu > Settings > Boiler > Limitations

Operating line

Range

Factory setting

Delta boiler temp max (stage 2)

0…10 K

1 K

To prevent pressure shocks in the gas network when stages 1 and 2 are simultane-

ously switched off, stage 2 is switched off before the maximum boiler temperature is

reached, the difference being “Delta boiler temp max (stage 2)“.

When the boiler is locked, stage 1 is switched off after stage 2, the difference in time

being 10 seconds.

Faulty return tempera-

ture sensor